Standby power supply system of steel rail milling and grinding vehicle and seamless switching method thereof

A technology for rail milling and grinding vehicles and backup power supply, which is applied in the direction of power network operating system integration, emergency power supply arrangement, information technology support system, etc. Loss and other problems, to avoid the loss of processing data, facilitate maintenance and maintenance, and improve the effect of operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

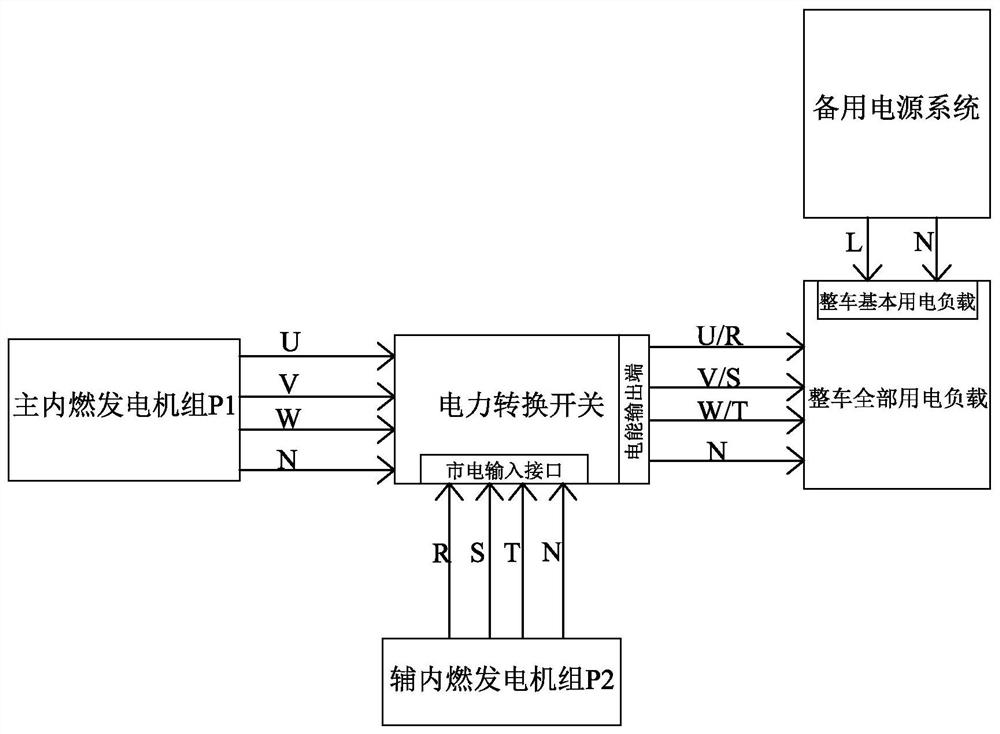

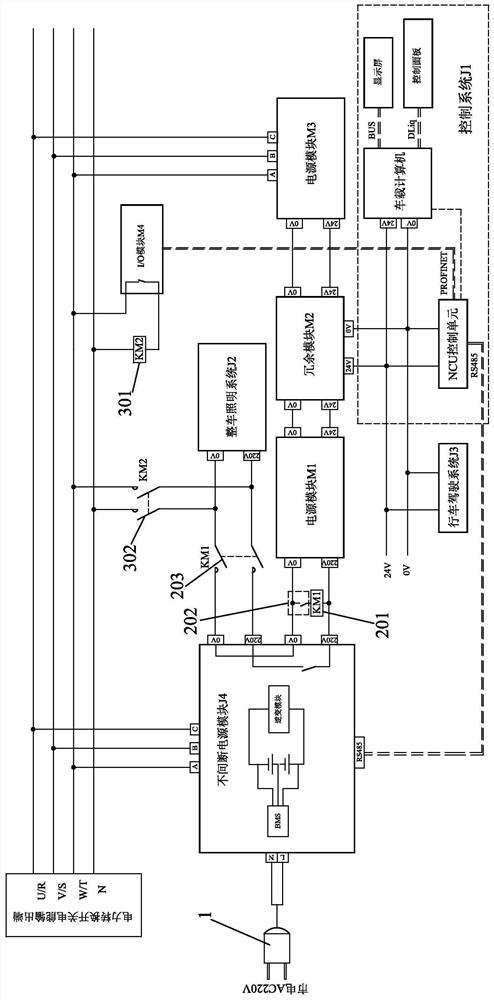

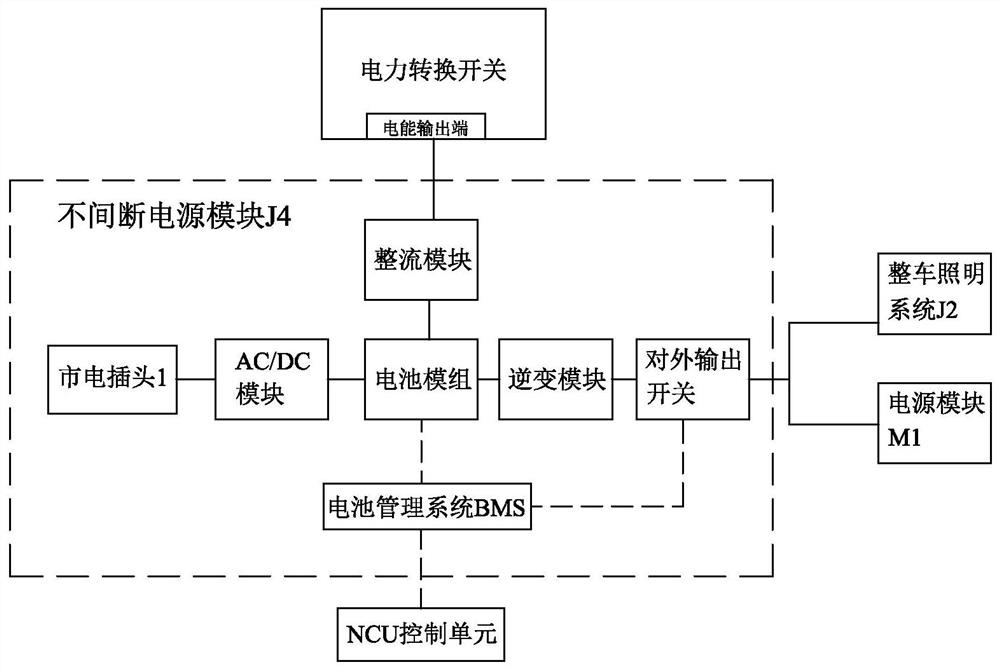

[0035] see Figure 1 to Figure 3In this embodiment, a backup power supply system for a rail milling and grinding car includes a power car II, a power car I and an operating vehicle that are sequentially connected from back to front in the working direction of the rail milling and grinding car. The operating car performs milling and grinding operations in front, The power car Ⅰ is polished and polished behind and provides the power source of the whole vehicle to drive the work vehicle. The power car Ⅱ is set behind the power car Ⅰ as a backup power source. The power car I is equipped with a main internal combustion generator set P1, and the power car II is equipped with an auxiliary internal combustion generator set P2. The power output terminal of P2 is connected to the mains input interface of the power c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com