Raw material mixing device and process for hygroscopicity-improved nylon 6

A mixing device and improved technology are applied in the field of raw material mixing devices of hygroscopic improved nylon 6, which can solve the problems of wide process temperature range, reduced hygroscopicity, and high shrinkage rate, and achieve effective hygroscopicity, reduced hygroscopicity, and improved hygroscopicity. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

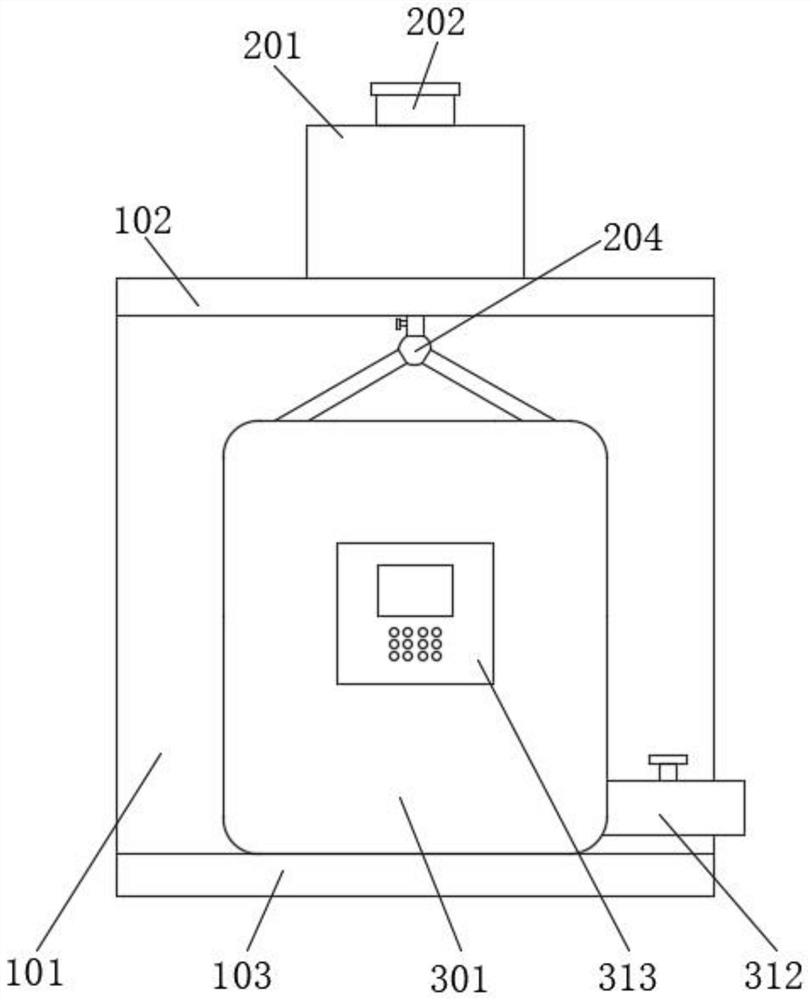

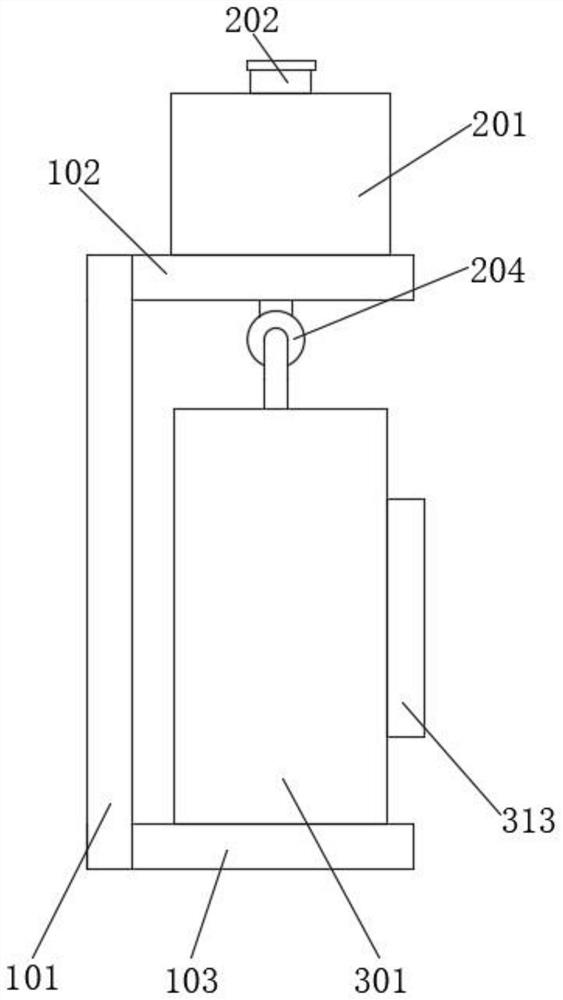

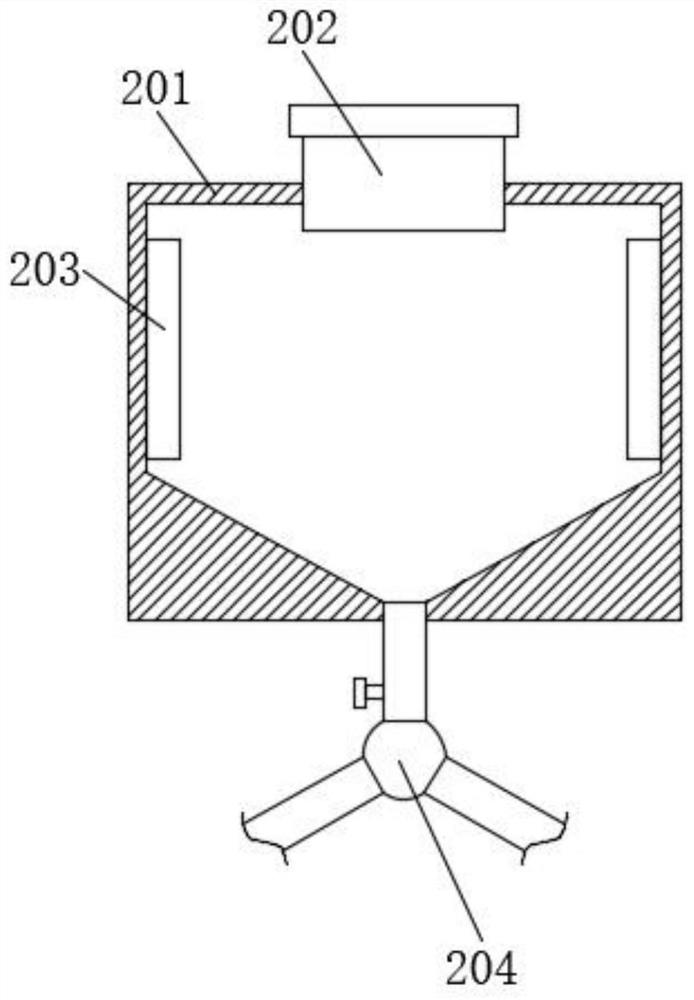

[0043] see Figure 1-7 , a raw material mixing device for hygroscopic improved nylon 6, including a support mechanism, a heating and mixing mechanism, and a stirring and mixing mechanism. The support mechanism includes a vertical support plate 101. The bottom end of the plate 101 is fixedly connected with a lower support plate 103, and the heating and mixing mechanism includes a heating box 201. The top outer wall of the heating box 201 is connected with a feed pipe 202, and the inner walls on both sides of the heating box 201 are fixedly connected with electric heating blocks. 203, through the setting of the heating box 201, the feed pipe 202, and the electric heating block 203, the raw materials can be heated and melted, so that the caprolactam and the modifier are initially mixed, and the bottom end of the heating box 201 is connected with a three-way pipe 204, stirring The mixing mechanism includes a stirring box 301, the heating box 201 is fixedly installed on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com