A Chip Clamping and Fixing and Chip Parallelism Measuring Structure for Ultrasonic Bonding

A clamping and fixing, ultrasonic bonding technology, applied in the direction of measuring devices, mechanical measuring devices, workpiece clamping devices, etc., can solve the problems of worn chip back, difficult relative displacement, reduced bonding efficiency, etc., to reduce mutual Friction, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

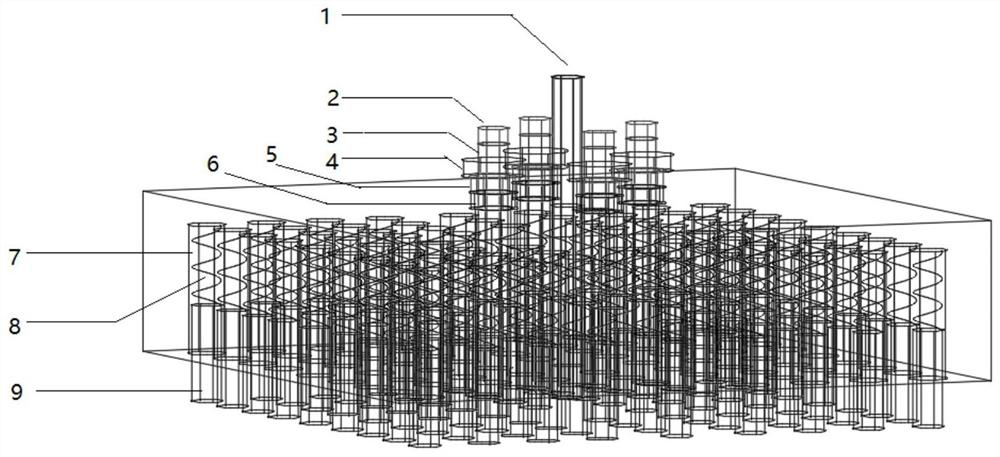

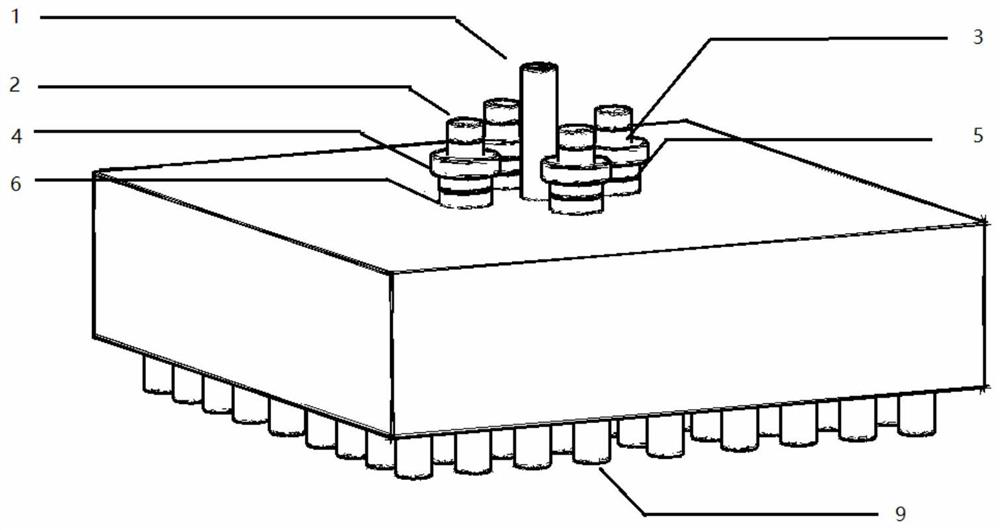

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

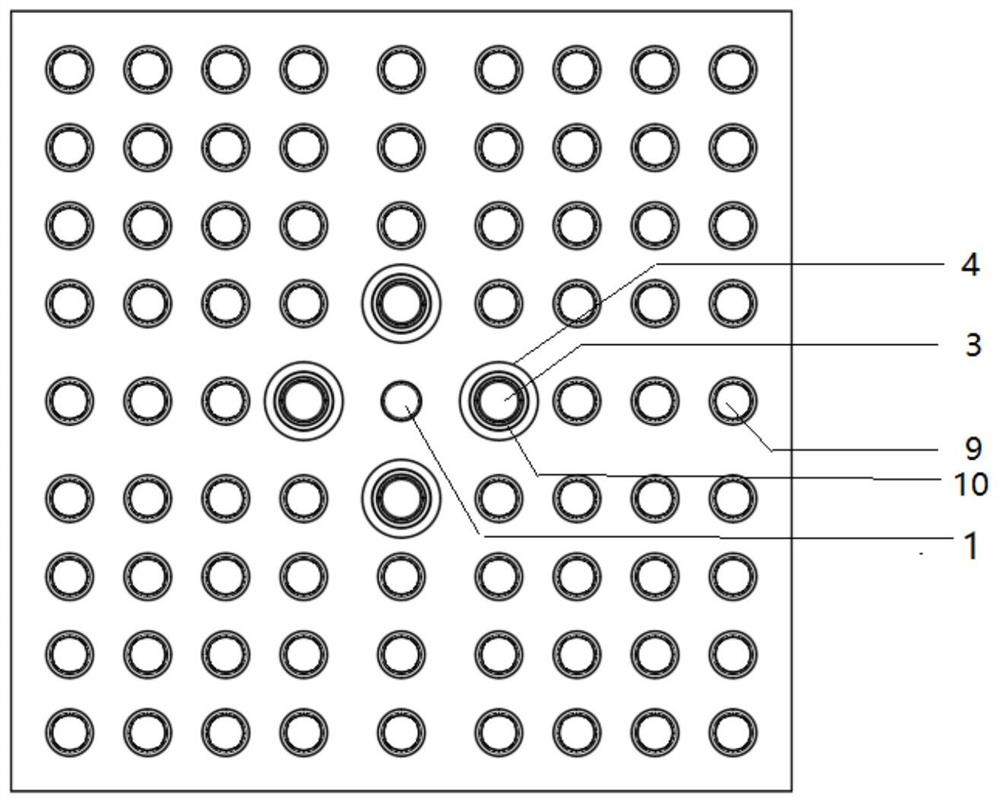

[0029] The invention designs a structure for ultrasonic flip-chip bonding chip clamping and chip parallelism measurement, which includes a long-pin chip parallelism measurement structure near the suction nozzle and a short-pin chip clamping and fixing structure outside.

[0030] like Figure 1-3 As shown, the long stitch parallelism measuring structure includes four fixing holes 10 , and the fixing holes 10 are evenly distributed around the suction nozzle 1 in a 90° distribution. 4 identical long pins 3 are located in the fixing holes 10 and can move up and down. The diameter of the long pins 3 is slightly smaller than the diameter of the fixing holes. Near the upper end of the long pin 3, an anti-falling cylindrical ring 4 with a diameter larger than the fixing hole 10 is arranged to prevent the long pin 3 from falling, and at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com