Online hot standby method for fan device of ethylene cracking furnace

An ethylene cracking furnace and a technology for cracking furnaces, which are applied to pump devices, mechanical equipment, and components of pumping devices for elastic fluids, etc., can solve problems such as affecting the normal operation of ethylene cracking furnaces and affecting the production efficiency of ethylene cracking furnaces. To achieve the effect of increasing elasticity and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

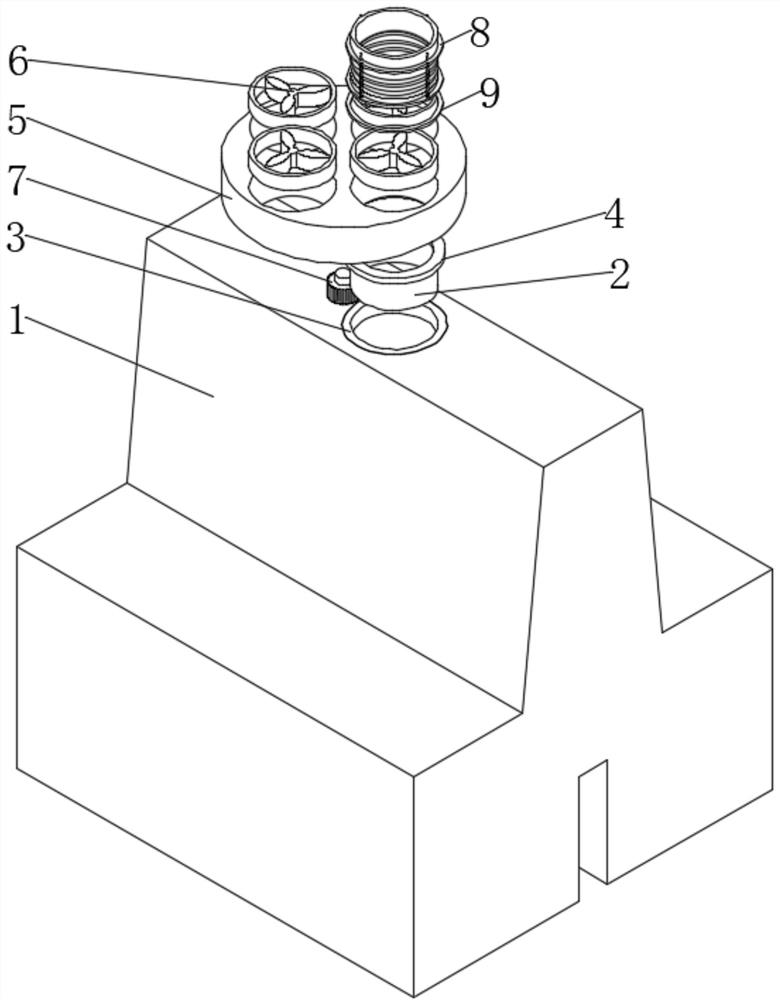

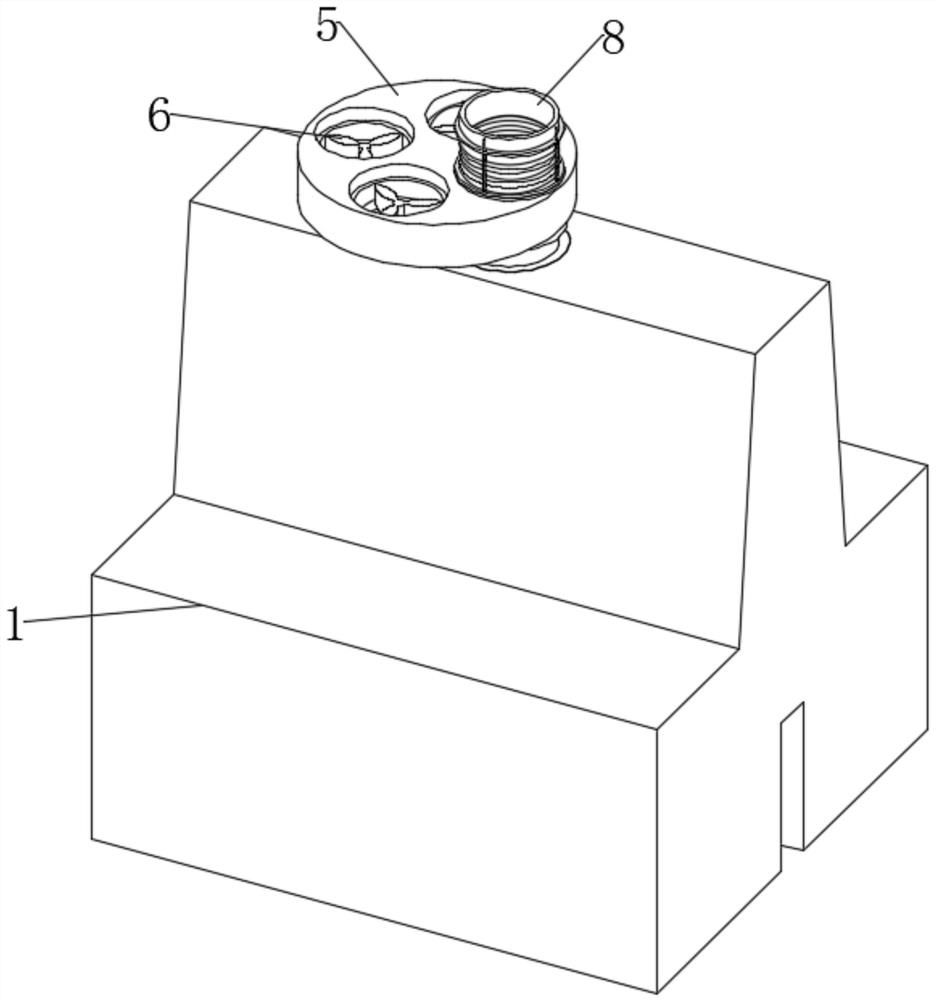

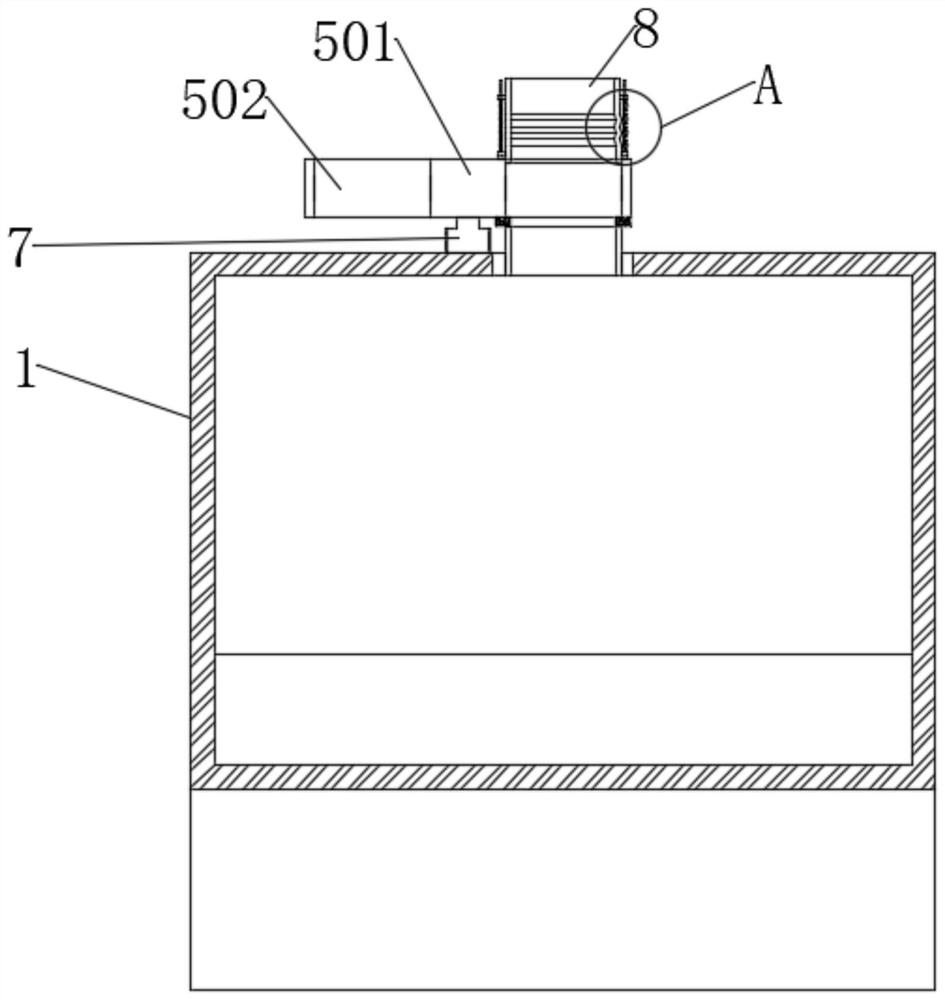

Image

Examples

Embodiment 1

[0037] Preparation Method A thermal line ethylene cracking furnace blower apparatus, comprising the main steps:

[0038]S1, fan monitoring, the fan for ventilation of the ethylene cracking furnace is set to a working fan, using the sensor loaded in the fan to real-time monitoring of the working position fan speed and working temperature, where the sensor setting is the monitoring method The technical technician is known to the present application, and those skilled in the art can easily complete the setting and use of the sensor according to the prior art;

[0039] S2, fan replacement, in the wind turbine working time reaches the preset standard or the speed of the fan does not reach the preset standard, in a state where the ethylene cleavage furnace is not stopped, the fans of the working position are replaced, and the technical personnel are arranged The fan replaced on the workplace is maintained and maintained, of which preset criteria requires preset according to the actual p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com