Rack gear-sector pair with variable transmission clearance characteristic and automobile steering gear

A rack-tooth and variable transmission technology, which is applied to steering gears, mechanical steering gears, steering mechanisms, etc., can solve problems such as complex manufacturing process, high difficulty in processing and testing, and transmission gap characteristic curves that cannot meet the design requirements. Process and detection of simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with accompanying drawing.

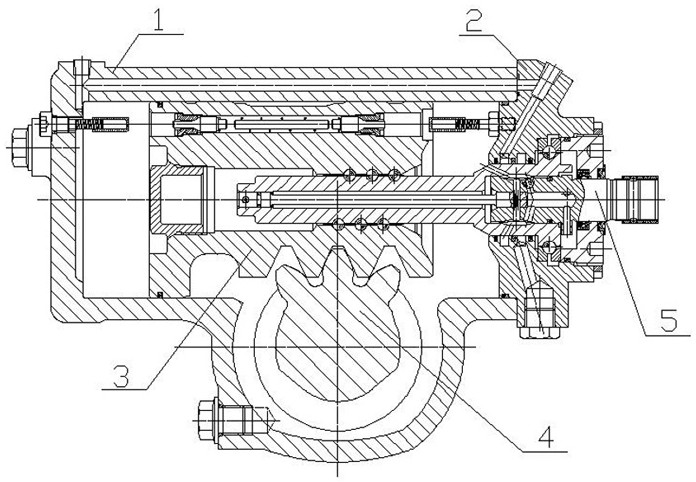

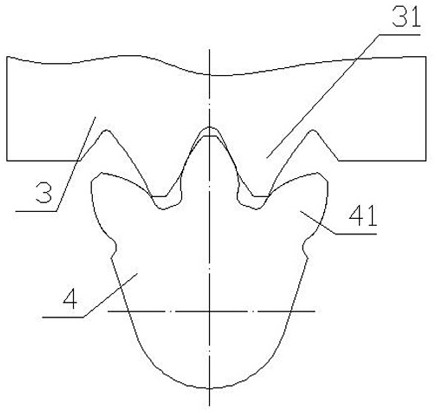

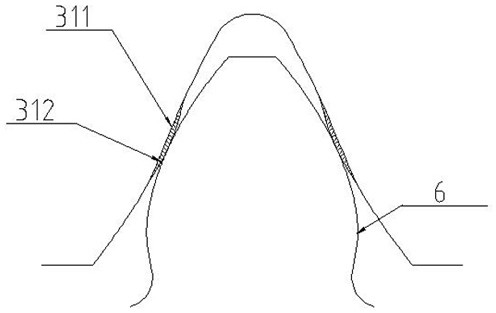

[0017] figure 1 The automobile steering gear involved in the present invention includes a housing 1, a valve body 2, a piston 3, a rocker shaft 4, and a steering control valve 5. The housing 1 and the valve body 2 are fixedly connected, and the steering control valve 5 is installed on the valve body 2. and cooperate with the piston 3, the rocker shaft 4 is installed on the housing 1, the gear fan on the rocker shaft 4 cooperates with the rack function part on the piston 3, the piston 3 is located in the inner cylinder hole of the housing 1 and can Moving left and right, the rocker shaft 4 is driven to rotate clockwise or counterclockwise through the cooperation of the teeth. The tooth fan and the rack function part in the example of the present invention adopt the variable transmission ratio design, so the tooth shape of the rack tooth part is not the straight line tooth shape of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com