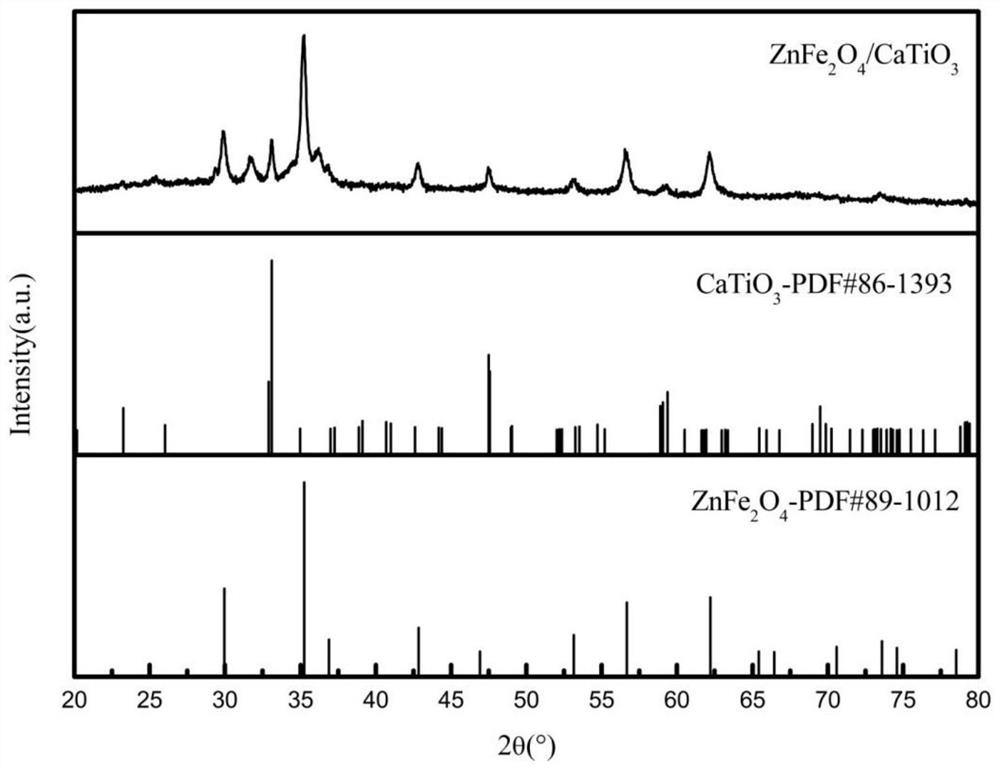

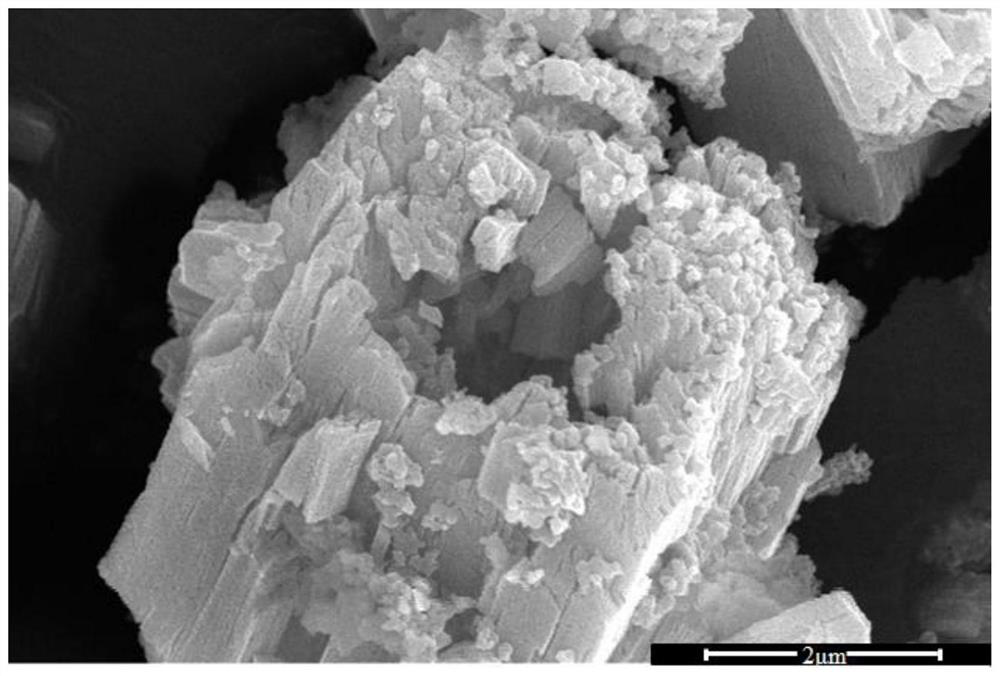

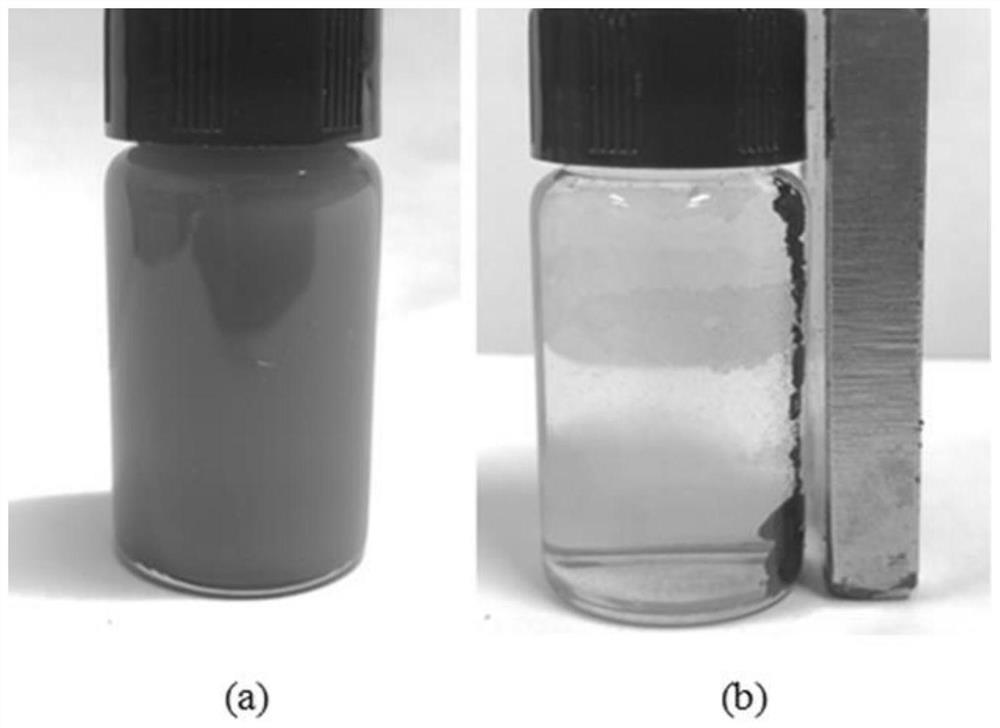

Hollow columnar ZnFe2O4/CaTiO3 composite material and preparation method thereof and application thereof

A composite material, znfe2o4 technology, applied in water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalyst, other chemical processes, etc., can solve problems such as high energy consumption, high price, and difficult recycling , to achieve energy saving, uniform distribution, and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Wash the fresh leaves with deionized water first, cut off the edges of the leaves with scissors, cut the leaves into pieces of about 3mm*3mm, and store them in a dark place for later use;

[0050] (2) Weigh 0.3525g CaCO 3 Place in 10mL deionized water and stir 180W ultrasonically for 20min to obtain calcium source suspension, weigh 0.5287g TiOSO 4 Place in 10mL of deionized water with 180W ultrasonic stirring for 20min, then continue stirring at 40°C to obtain a titanium source solution, and weigh 0.1438g of ZnSO 4 ·7H 2 O was dissolved in 5mL deionized water to obtain a zinc source solution, and 0.2781g FeSO was weighed 4 ·7H 2 O was dissolved in 8 mL deionized water to obtain iron source solution, and 0.1796 g H 2 C 2 o 4 Place in 10mL deionized water and stir to dissolve to obtain H 2 C 2 o 4 solution, weigh 1.000g CO(NH 2 ) 2 Place in 10mL deionized water and stir evenly to obtain CO(NH 2 ) 2 solution;

[0051] (3) mixing and stirring the zinc sour...

Embodiment 2

[0061] (1) Wash the fresh leaves with deionized water first, cut off the edges of the leaves with scissors, cut the leaves into pieces of about 3mm*3mm, and store them in a dark place for later use;

[0062] (2) Weigh 0.5000g CaCO 3 Place in 15mL deionized water and stir 180W ultrasonically for 30min to obtain calcium source suspension, weigh 0.7000g TiOSO 4 Place in 15mL of deionized water and stir 180W ultrasonically for 30min, then continue to stir at 40°C to obtain a titanium source solution, weigh 0.1650g ZnSO 4 ·7H 2 O was dissolved in 5mL deionized water to obtain a zinc source solution, and 0.3350g FeSO 4 ·7H 2 O was dissolved in 10mL deionized water to obtain iron source solution, and 0.2178g H 2 C 2 o 4 Place in 10mL deionized water and stir to dissolve to obtain H 2 C 2 o 4 solution, weigh 1.000g CO(NH 2 ) 2 Place in 15mL deionized water and stir evenly to obtain CO(NH 2 ) 2 solution;

[0063] (3) mixing and stirring the zinc source solution and the ir...

Embodiment 3

[0072] (1) Wash the fresh leaves with deionized water first, cut off the edges of the leaves with scissors, cut the leaves into pieces of about 3mm*3mm, and store them in a dark place for later use;

[0073] (2) Weigh 0.8000g CaCO 3 Place in 15mL deionized water and stir 180W ultrasonically for 25min to obtain calcium source suspension, weigh 1.3280g TiOSO 4 Place in 15mL of deionized water and stir 180W ultrasonically for 30min, then continue to stir at 40°C to obtain titanium source solution, weigh 0.2180g ZnSO 4 ·7H 2 O was dissolved in 8mL deionized water to obtain a zinc source solution, and 0.4500g FeSO was weighed 4 ·7H 2 O was dissolved in 15mL deionized water to obtain iron source solution, and 0.2870g H 2 C 2 o 4 Place in 12mL deionized water and stir to dissolve to obtain H 2 C 2 o 4 solution, weigh 1.000gCO(NH 2 ) 2 Place in 10mL deionized water and stir evenly to obtain CO(NH 2 ) 2 solution;

[0074] (3) mixing and stirring the zinc source solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com