A special drainage sand for high manganese and high aluminum steel and its application method

A technology for draining sand and high-aluminum steel, applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of rising production costs and high prices, and achieve the effects of cost reduction, cost control, and risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

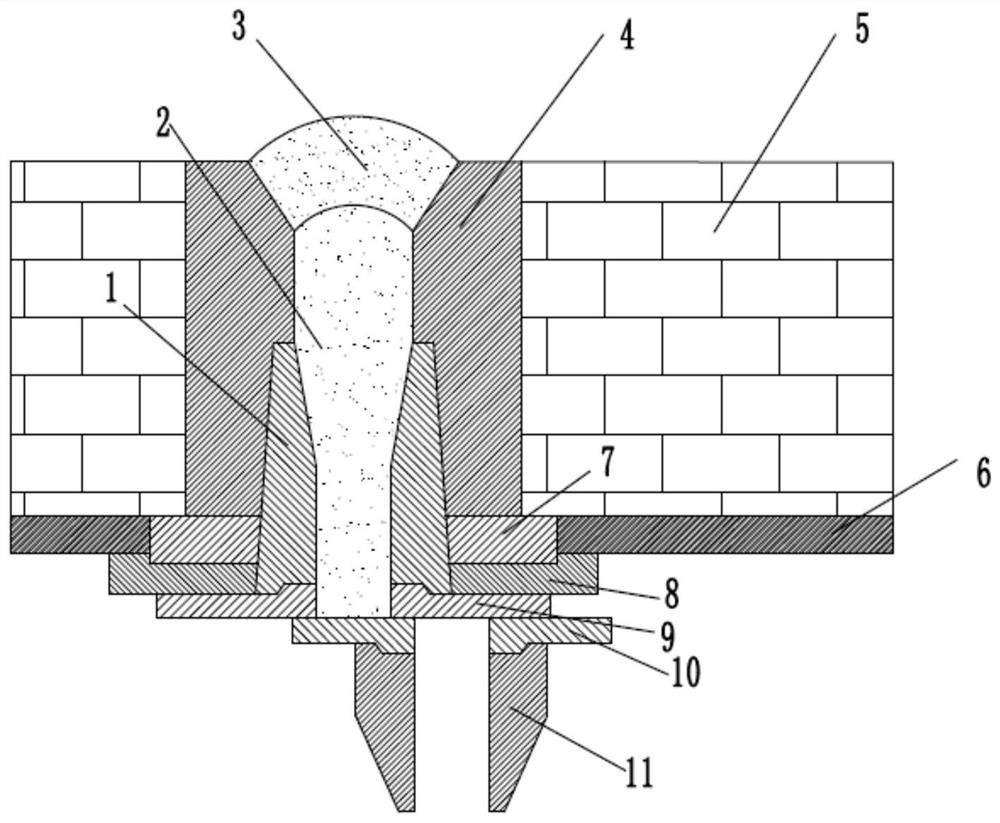

[0029] A special drainage sand for high manganese and high aluminum steel and its application method, such as figure 1 shown. The present embodiment is applied to a 120-ton ladle to produce the technological process of 20Mn23AlV.

[0030] Such as figure 1 As shown, after the ladle has been used for one heat, the lower nozzle, slide plate and upper nozzle are cleaned by burning oxygen; the oxygen blowing pipe is aligned with the nozzle and pushed in parallel to clean the cold steel and residue in the nozzle for 3 minutes about. Lift the ladle with the nozzle cleaned to the ladle car, transport the ladle to the drainage sand installation platform through the ladle car, close the sliding nozzle, install the conduit through the drainage sand, add the chrome drainage sand to the ladle nozzle block, The chrome drainage sand, Cr 2 o 3 =40%, Al 2 o 3 =10%, SiO 2 =20%, Fe 2 o 3 = 25%, MgO = 5%, sand size: 0.1-1mm, of which 15% are in the range of 0.1-0.3mm, 60% are in the ran...

Embodiment 2

[0032] A special drainage sand for high manganese and high aluminum steel and its application method, such as figure 1 shown. This embodiment is applied to an 80-ton ladle to produce the technological process of X35Mn18.

[0033] Such as figure 1As shown, after the ladle is used for one heat, the ladle is maintained, the ladle with the nozzle cleaned is hoisted to the ladle car, and the ladle is transported to the drainage sand installation platform by the ladle car, the sliding nozzle is closed, and the drainage sand is added. Install the conduit, add chrome drainage sand to the ladle nozzle seat brick, the chromium drainage sand, Cr 2 o 3 =35%, Al 2 o 3 = 7%, SiO 2 =25%, Fe 2 o 3 = 25%, MgO = 8%, sand size: 0.1-1mm, of which 20% are in the range of 0.1-0.3mm, 60% are in the range of 0.3-0.7mm, and 0.7- Particles in the 1mm range accounted for 20%. Fill the chrome drainage sand until the upper surface is 3-7cm lower than the top of the nozzle block. After filling th...

Embodiment 3

[0035] A special drainage sand for high manganese and high aluminum steel and its application method, such as figure 1 shown. The present embodiment is applied to a 100-ton ladle to produce the technological process of X120Mn12.

[0036] Such as figure 1 As shown, after the ladle is used for one heat, the ladle is maintained, the ladle with the nozzle cleaned is hoisted to the ladle car, and the ladle is transported to the drainage sand installation platform by the ladle car, the sliding nozzle is closed, and the drainage sand is added. Install the conduit, add chrome drainage sand to the ladle nozzle seat brick, the chromium drainage sand, Cr 2 o 3 =30%, Al 2 o 3 =12%, SiO 2 =28%, Fe 2 o 3 = 20%, MgO = 10%, sand size: 0.1-1mm, of which 30% are in the range of 0.1-0.3mm, 60% are in the range of 0.3-0.7mm, and 60% are in the range of 0.7-0.7mm Particles in the 1mm range accounted for 10%. Fill the chrome drainage sand until the upper surface is 3-7cm lower than the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com