New energy automobile hub forging process

A new energy vehicle and wheel hub forging technology is applied in the field of wheel hub forging, which can solve the problems of increasing the work tasks of lathes, reducing the wheel hub forging efficiency, and the waste of wheel hub materials, so as to achieve the effects of improving cutting efficiency, reducing production costs and improving forging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

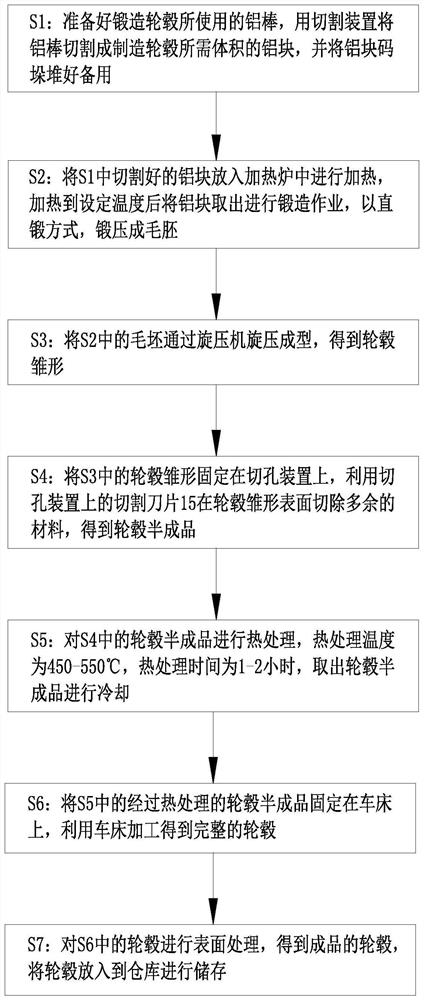

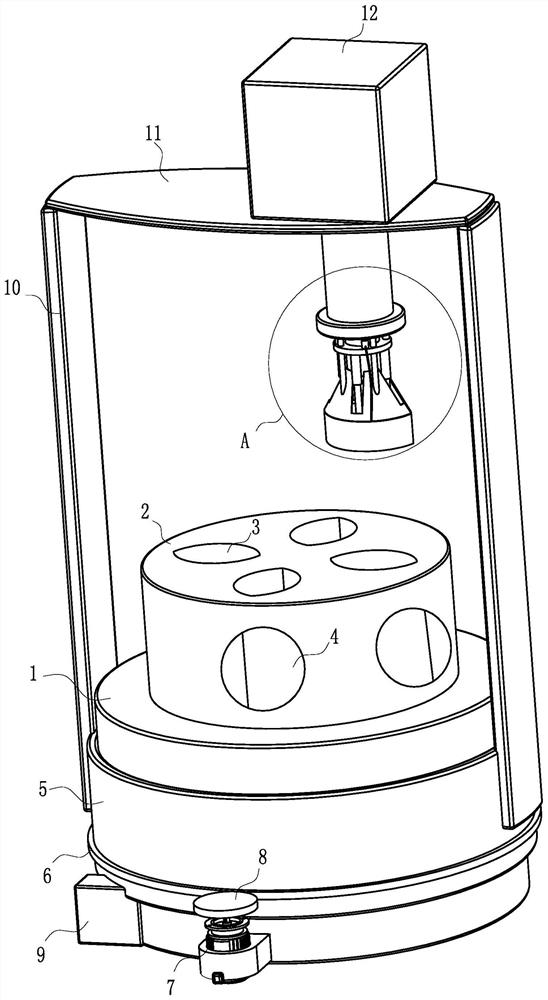

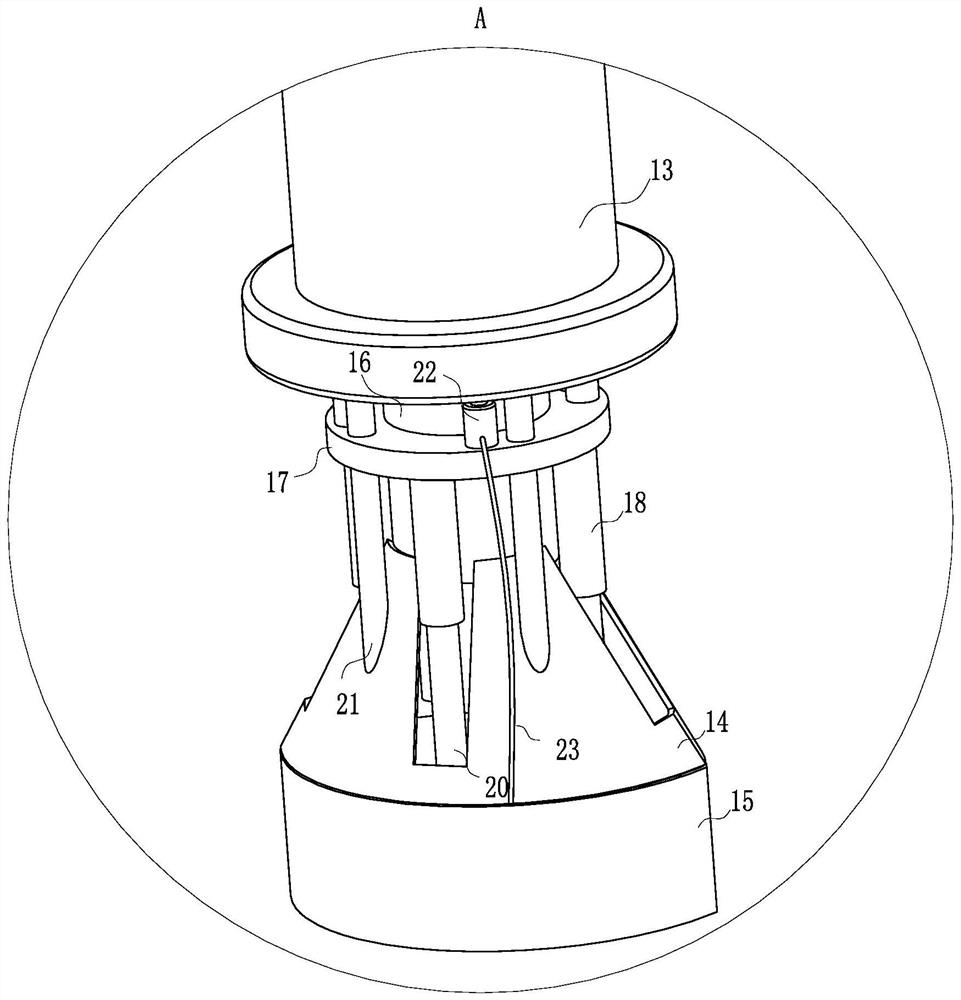

[0032] Such as Figure 1 to Figure 6 As shown, a kind of new energy vehicle hub forging process described in the present invention comprises the following steps:

[0033] S1: Prepare the aluminum rods used for forging the wheels, use the cutting device to cut the aluminum rods into aluminum blocks of the volume required for manufacturing the wheels, stack the aluminum blocks for use, and cut out different sizes of aluminum according to different sizes of wheels block, which not only ensures the accurate size of the finished product, but also avoids the waste of materials;

[0034] S2: Put the aluminum block cut in S1 into the heating furnace for heating, and after heating to the set temperature, take out the aluminum block for forging operation, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap