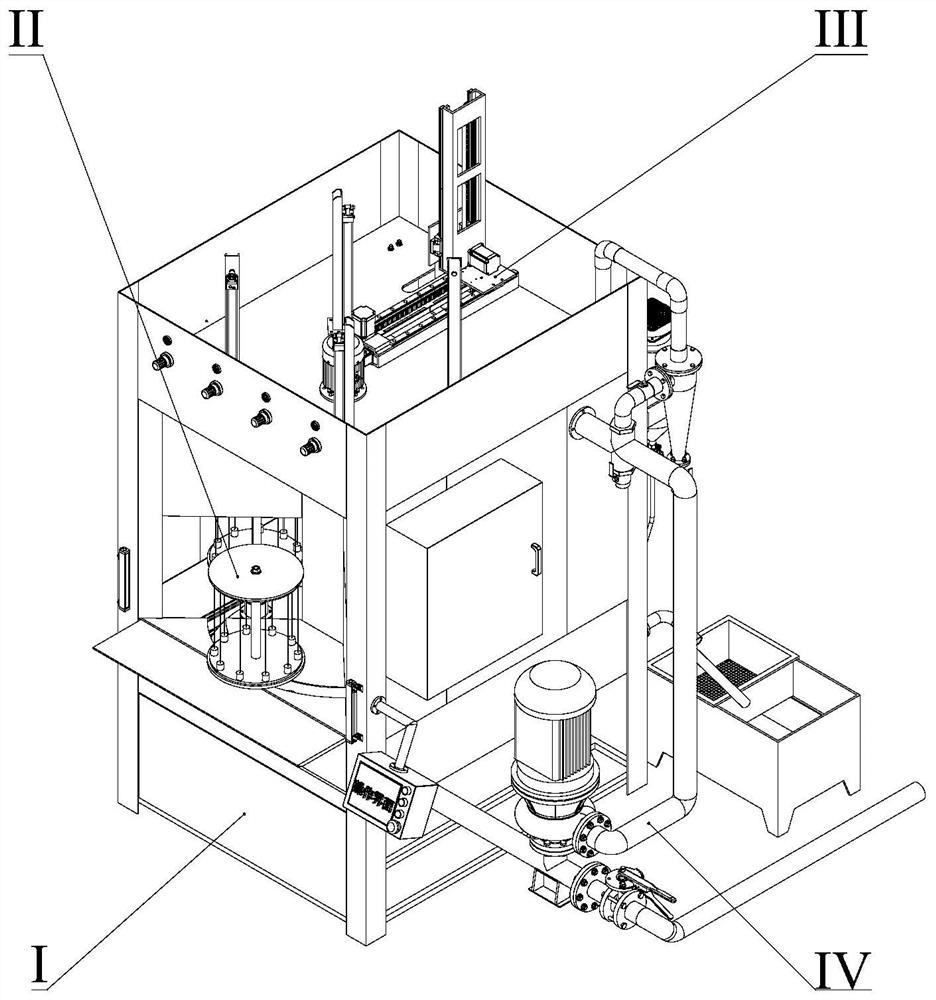

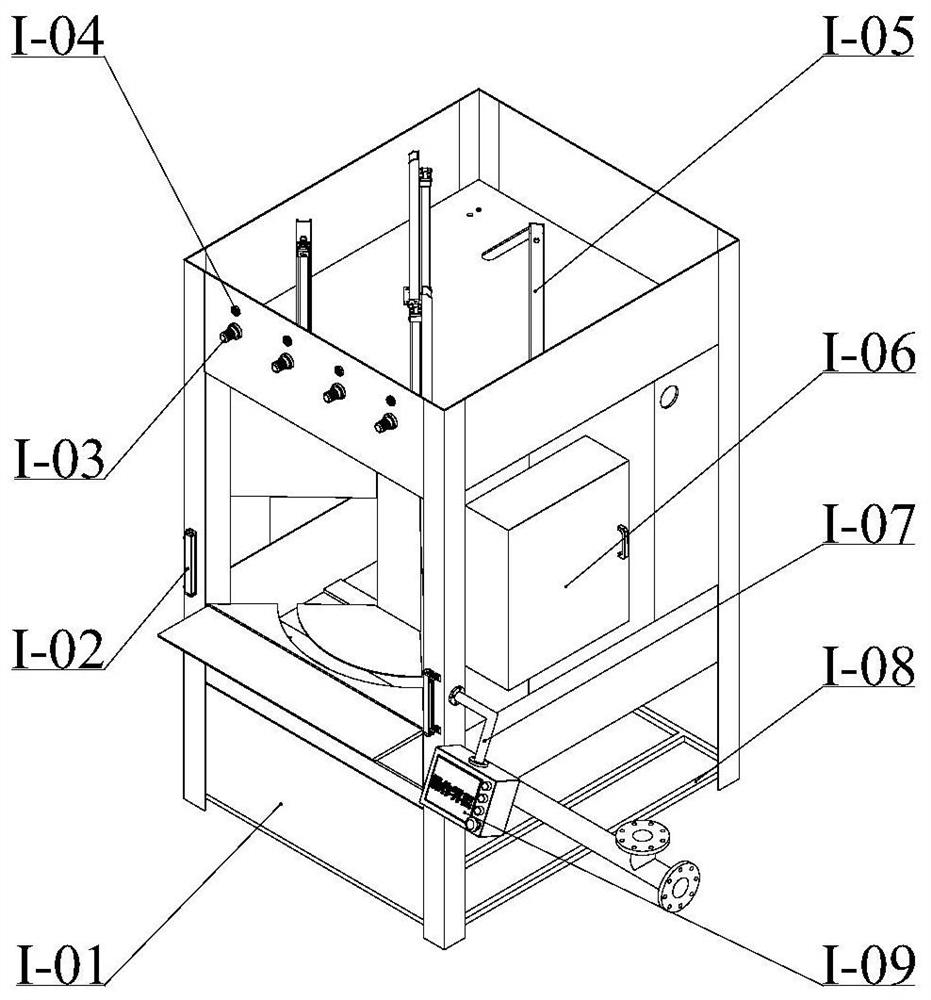

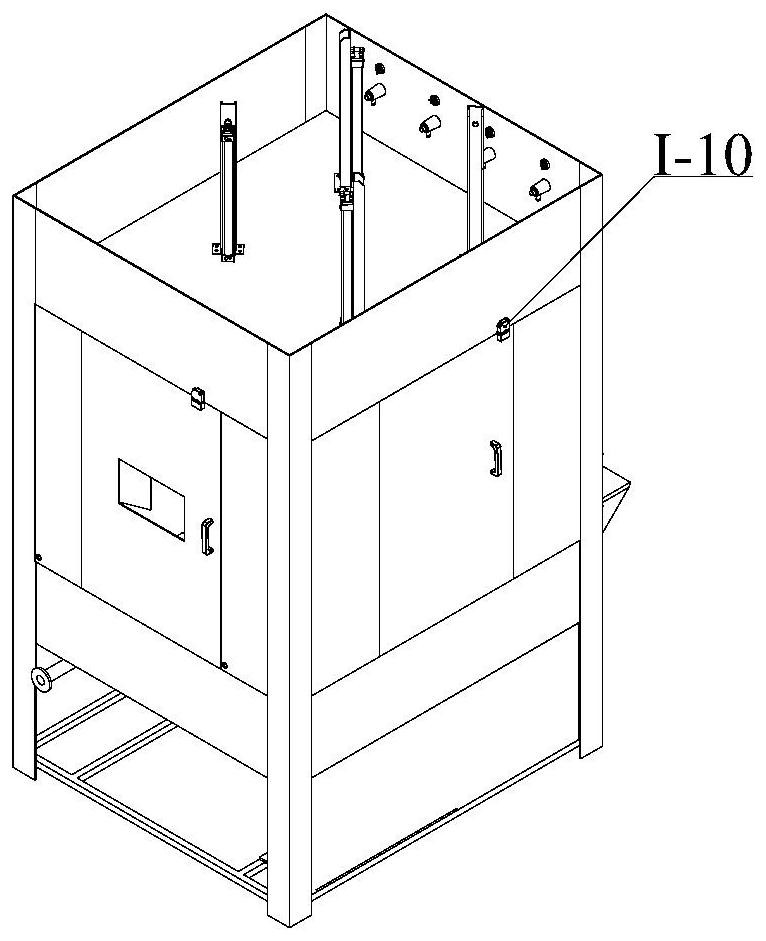

A hard alloy tool passivation device and working method

A cemented carbide and cutting tool technology, which is applied in the field of cemented carbide cutting tool passivation devices, can solve the problems of environmental pollution, small sandblasting coverage, hidden dangers to the safety of workers, etc. Sand uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0158] This embodiment discloses the working method of the cemented carbide tool passivation device described in Embodiment 1:

[0159] Abrasives are placed in the collection hopper. The abrasives can be added with vegetable abrasives, such as walnut sand and other soft abrasives, which can improve the passivation effect of the cutting edge. During the passivation work, the agitator installed in the collection hopper IV-09 starts to work. , stir the sand-water mixture evenly, start the grinding liquid pump IV-04, and transport the sand-water mixture in the collection bucket IV-09 along the sand suction pipe IV-03 to the sand outlet pipe assembly IV-07, and the sand-water mixture enters the outlet. The sand pipe IV-0702 and the sand outlet pipe IV-0702 have four outlets. The sand-water mixture enters the sand blasting pipe IV-0704 through the sand outlet pipe IV-0702 and then is transported all the way to the sand inlet joint III-010502 and enters the spray gun seat III -010503...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com