Sleeve grouting material mixed with iron filings and fine sand, its preparation method and supporting strength testing method

A sleeve grouting and fine sand technology, applied in the direction of material magnetic variables, can solve the problems of poor strength and insufficient fine sand strength, and achieve the effects of improving the strength and crack resistance of the slurry, reducing the deterioration of the mortar and reducing the overall cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

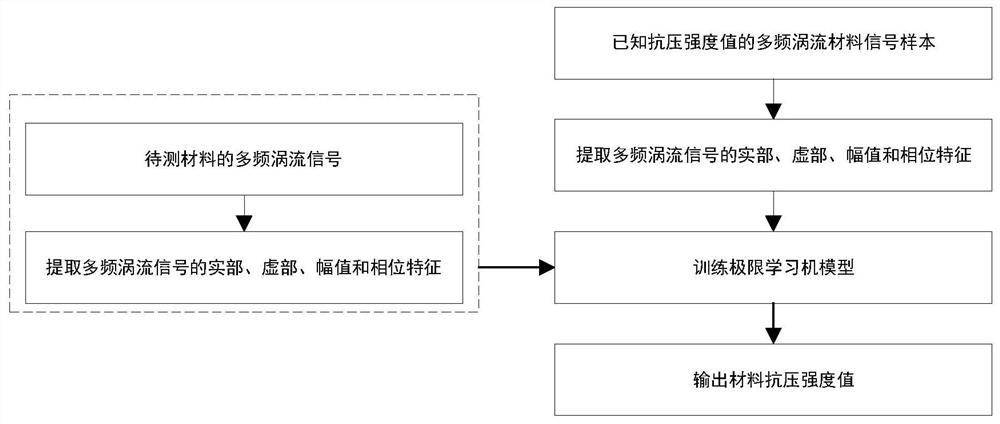

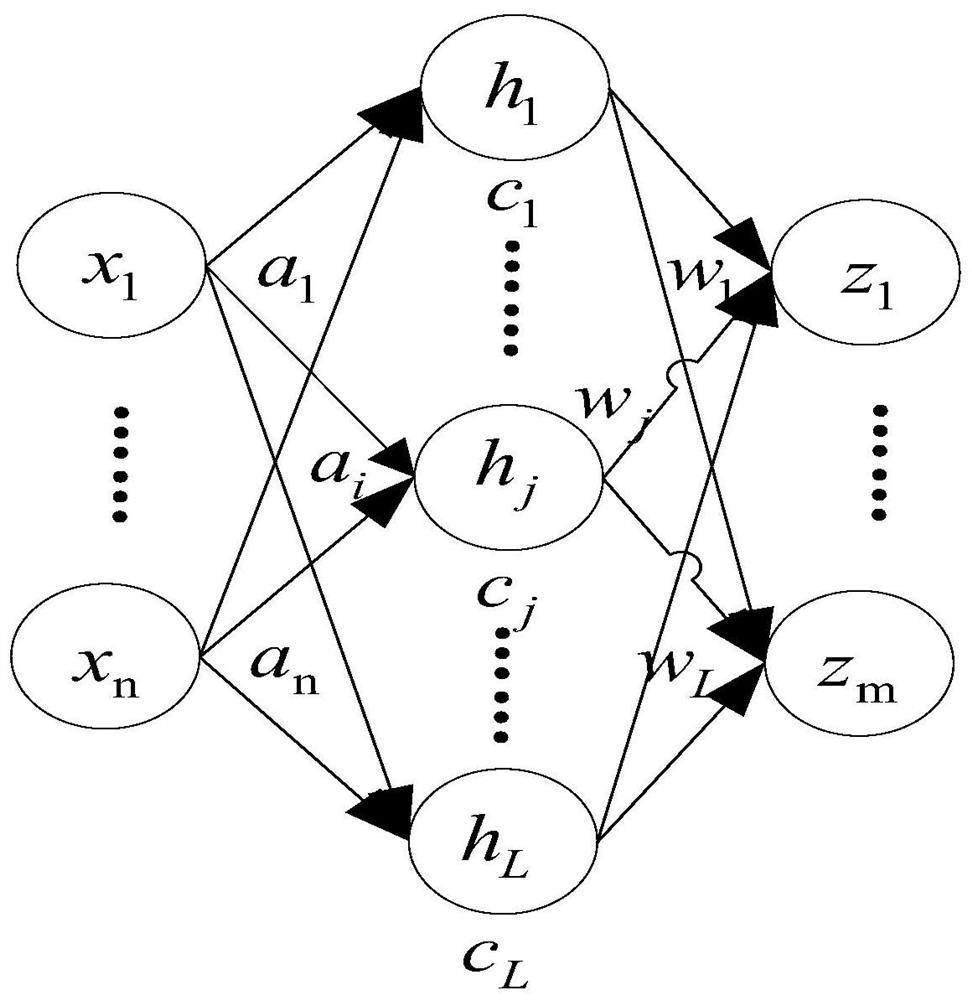

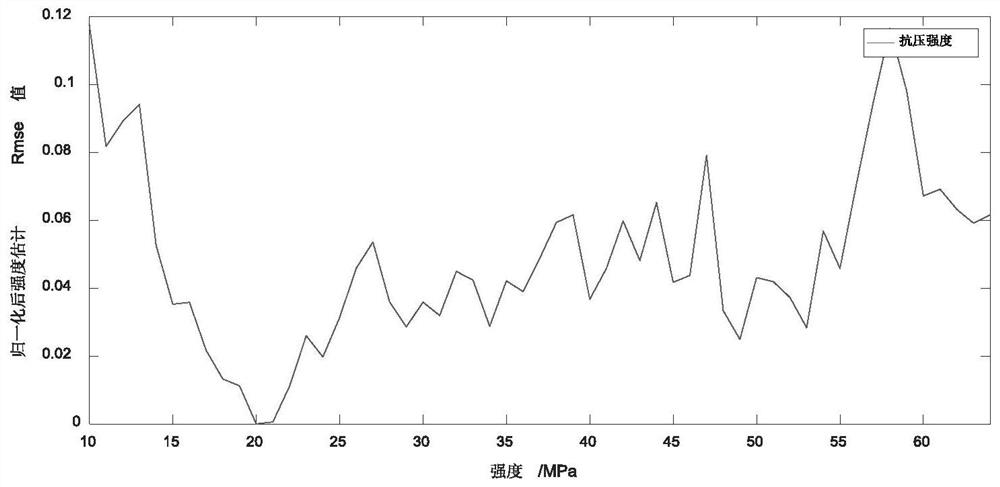

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0045] The invention provides sleeve grouting material mixed with iron filings and fine sand, its preparation method and matching strength detection method. This application uses processed iron filings fine sand to replace the aggregate in the original sleeve grouting material, which can greatly improve sleeve grouting after use. The strength of the sleeve grouting material, because this application is mainly prepared with pig iron filings, so the cost is low, and the prepared sleeve grouting material can be analyzed and tested in real time to ensure product reliability through compressive strength.

[0046]As a specific embodiment of the sleeve grouting material mixed with iron filings fine sand of the present invention, the sleeve grouting material of the present invention includes the following components in parts by weight: 100 parts of cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com