Scrap iron-doped fine sand sleeve grouting material and preparation method and matched strength detection method thereof

A technology of sleeve grouting and iron filings, which is applied in the direction of material magnetic variable, etc., can solve the problems of insufficient strength and poor strength of fine sand, improve the strength and crack resistance of the slurry, improve the crack resistance, and reduce the deterioration of mortar Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

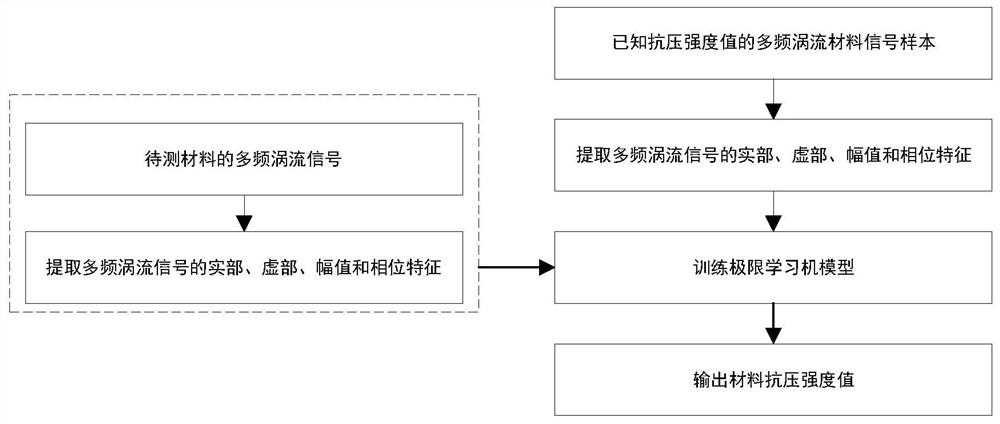

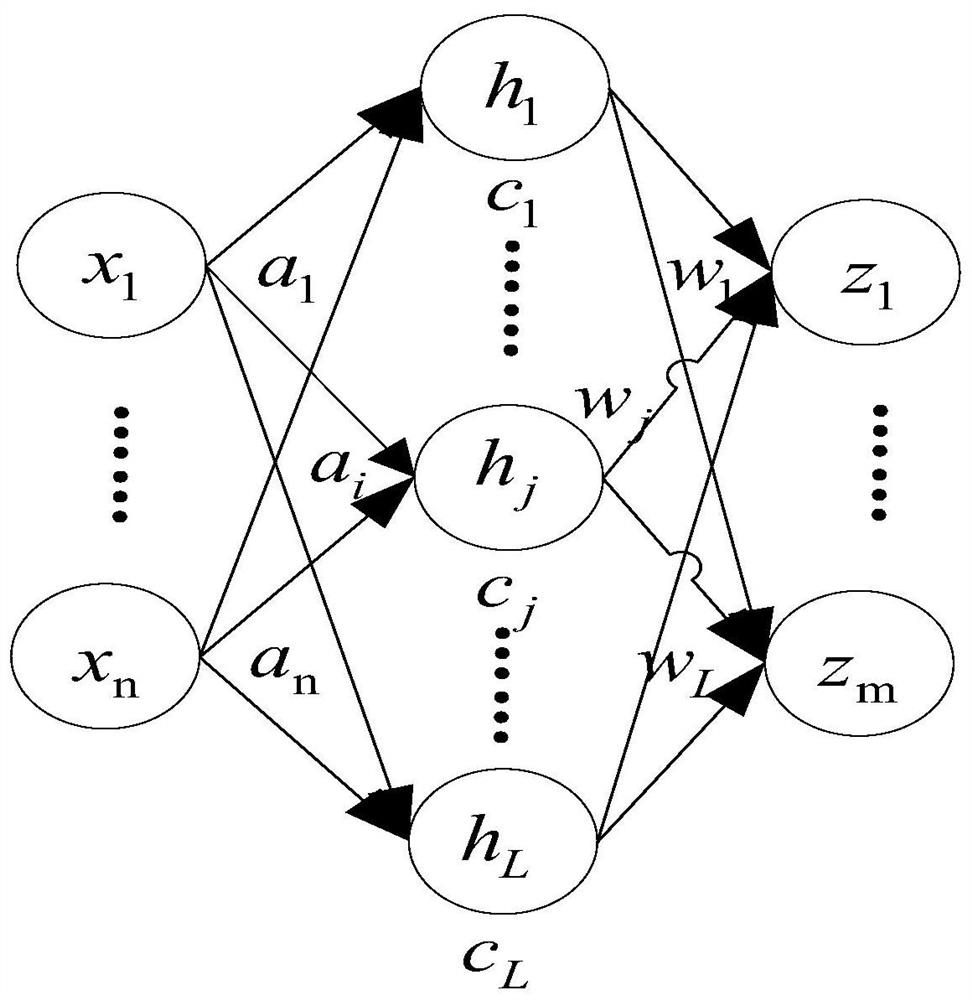

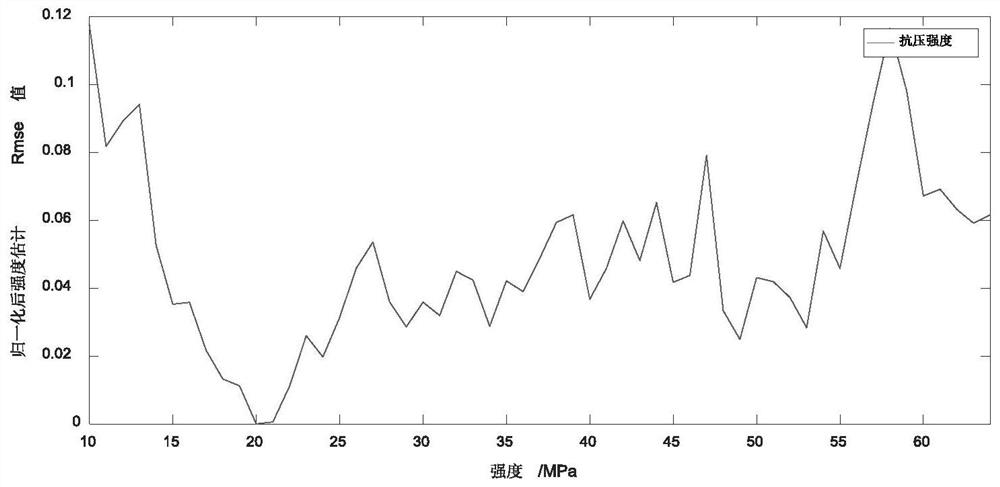

[0045] The present invention provides a sleeve grouting material mixed with iron filings and fine sand, and a preparation method and a supporting strength detection method. This application uses processed iron filings and fine sand to replace the aggregate in the original sleeve grouting material, which can greatly improve the sleeve after use. The strength of the barrel grouting material is low in cost because the application mainly uses pig iron filings to prepare it, and the prepared barrel grouting material can ensure product reliability through real-time rapid analysis and detection of compressive strength.

[0046] As a specific example of the sleeve grouting material mixed with iron filings and fine sand in the present invention, the sleeve grouting material of the present invention is calculated in parts by weight, including the following compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com