Steamer bottom structure of wine steamer for steaming Maotai-flavor wine

A sauce-flavored wine and retort bottom technology, which is applied in the field of winemaking, can solve the problems of uneven heat transfer and distillation, reduce distillation efficiency, and affect wine yield, etc., so as to improve distillation efficiency, ensure distillation effect, improve wine yield and The effect of distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

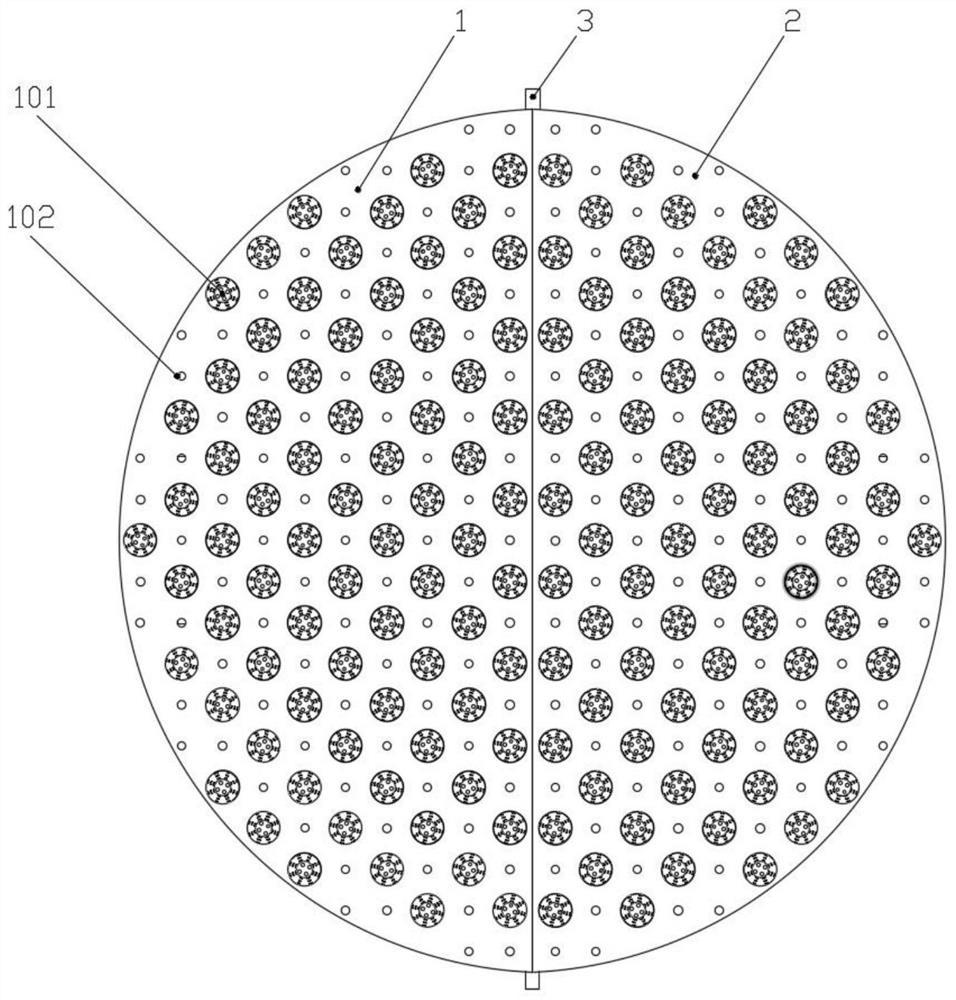

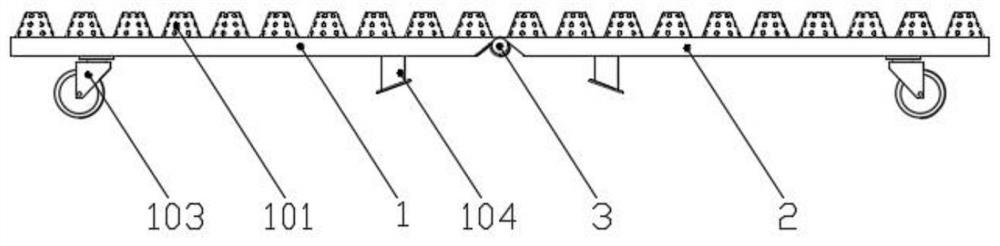

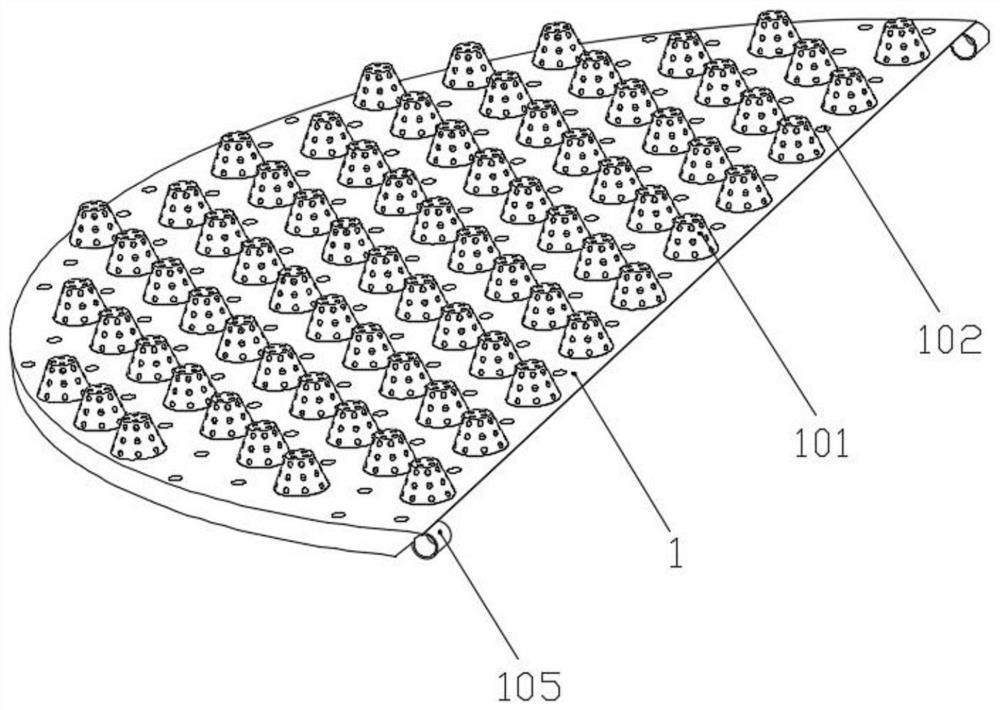

[0016] refer to Figure 1 to Figure 5 , this embodiment provides a wine retort bottom structure for steaming wine with sauce-flavored wine, including a circular retort bottom, the retort bottom is made of stainless steel, and the retort bottom is composed of semicircular and symmetrically arranged first retort bottom 1 and second retort bottom. The two retort bottoms 2 are butted together, and the first retort bottom 1 and the second retort bottom 2 are hinged through the hinge shaft 3 arranged along the symmetrical center line, and the upper surfaces of the first retort bottom 1 and the second retort bottom 2 are distributed with cones Platform 101 and circular hole 102, the diameter of circular hole 102 is 6mm, and conical truncated 101 is a hollow structure, and the bottom surface of conical truncated and the conical surface are distributed with the vent holes that run through the bottom of the retort and the conical surface, and the diameter of the vent holes is 3mm .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com