Dewatering treatment method for steeply inclined strip-shaped interbed composite stratum foundation pit

A treatment method, a strip-shaped technology, applied in the fields of construction engineering, urban rail transit, tunnel and underground engineering, can solve problems such as engineering and surrounding environmental safety accidents, upper diving and surrounding environmental changes, and prolonging the construction period, so as to reduce precipitation The number of wells, good economic and safety benefits, and the effect of saving construction period and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

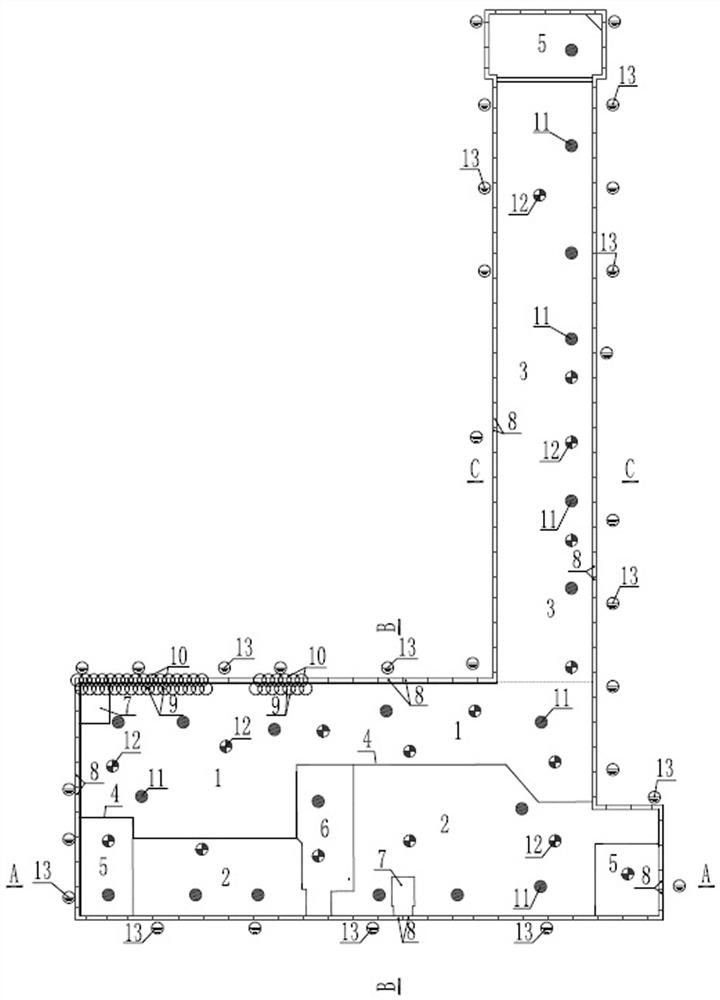

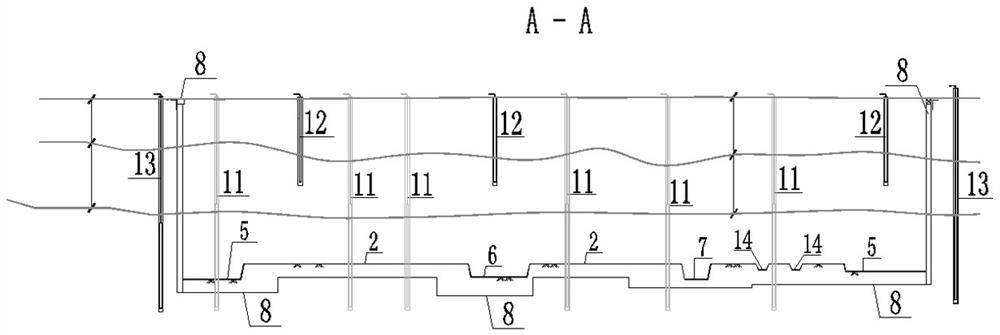

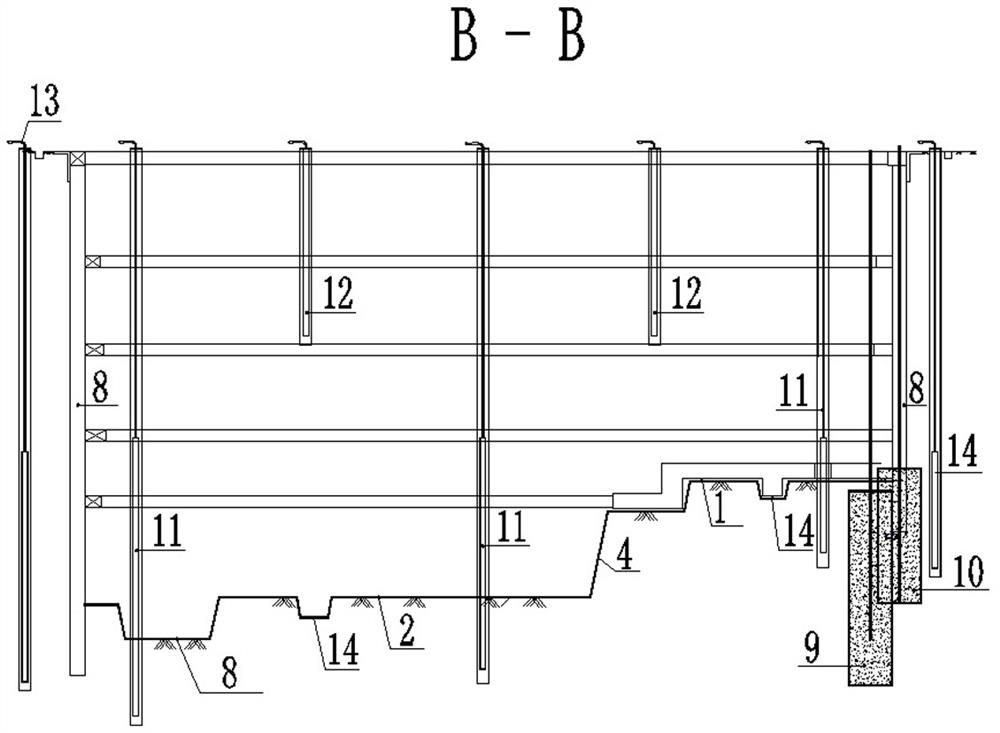

[0033] Such as Figure 1-4 As shown, a method for dewatering treatment of foundation pits in steeply inclined strip-shaped interlayer composite strata, the specific construction method is as follows:

[0034] Step 1, the underground diaphragm wall 8 of the foundation pit is completed; the foundation pit is composed of the shallow pit 1 of the open excavation hall, the deep pit 2 of the open excavation hall and the shallow pit 3 of the station; Excavation, and the shallow pit 1 of the open excavation hall and the deep pit 2 of the open excavation hall are connected by the shallow-deep pit boundary line 4;

[0035] Step 2. Drill grouting holes in the pre-buried casing of the underground diaphragm wall 8, and perform grouting 10 in the limestone cracks at the bottom of the wall according to the karst cave at the bottom of the wall; The surface is 5m below the bottom of the underground diaphragm wall 8, and the length is 9.5m;

[0036] Construct the inner grouting hole of the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com