Rock wall crane beam structure and construction method thereof

A technology of crane beams and rock walls, which can be applied to basic structure engineering, underwater structures, artificial islands, etc., and can solve problems such as unfavorable stability of caverns, failure to meet structural safety requirements, and insufficient anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

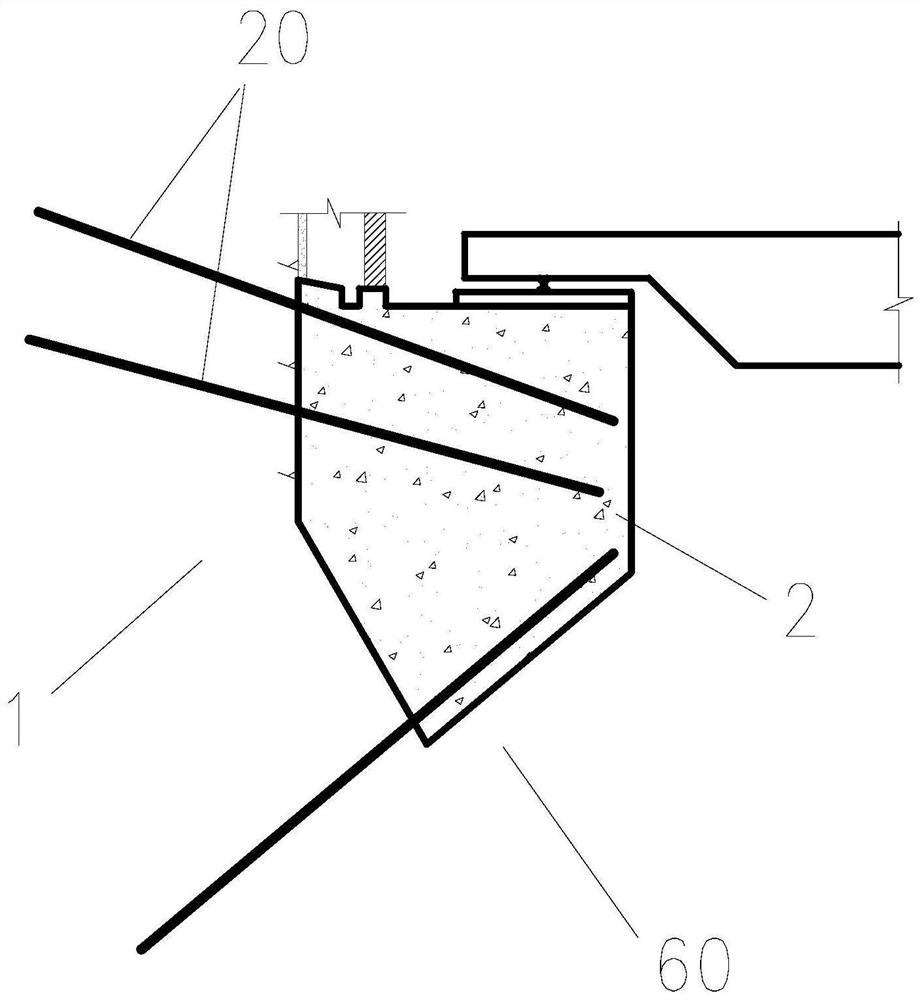

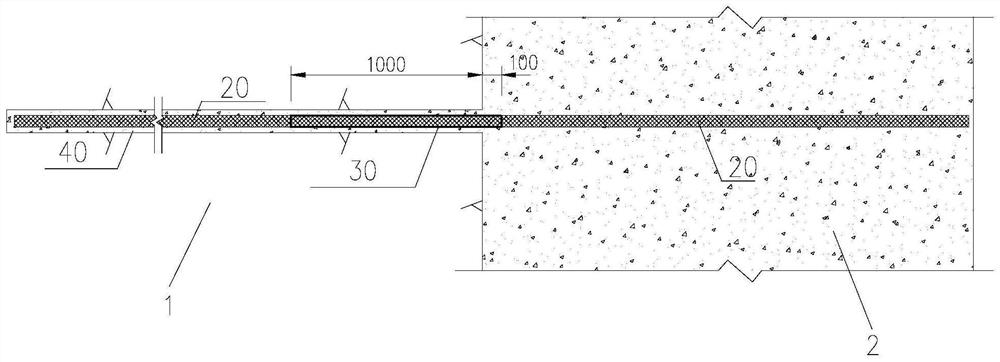

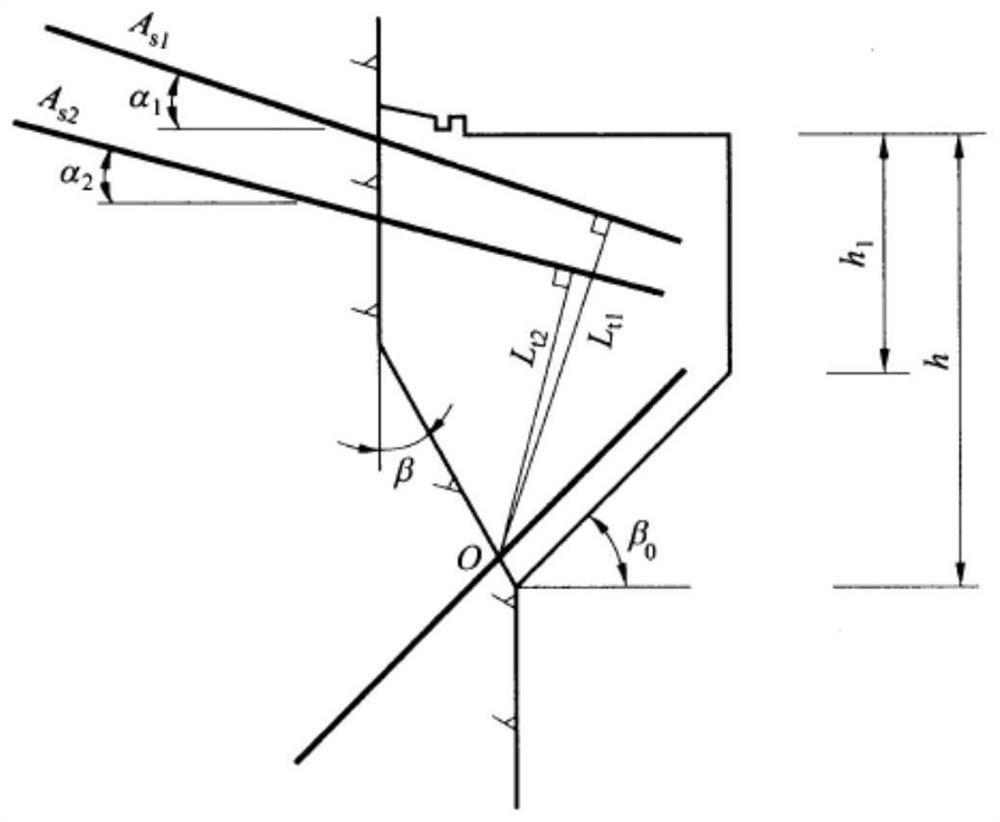

[0142] Such as Figure 4 As shown, the rock wall crane beam structure of this embodiment includes a rock wall crane beam 2 fixed on the wall surface of the surrounding rock 1 , and a plurality of prestressed anchor rods 3 connecting the surrounding rock 1 and the rock wall crane beam 2 .

[0143] The wall surface of the surrounding rock 1 is provided with anchor holes 11 corresponding to the prestressed anchor rods 3 one-to-one. The air pipe 8 and the accommodation pipe 7 run through the two walls of the rock wall crane beam 2 along the length direction of the prestressed anchor rod 3, and the inner cavity of the accommodation pipe 7 forms a through hole 21, and the anchor hole 11 communicates with the corresponding through hole 21 to form Accommodating holes.

[0144] One end of the oil injection pipe 7 is fixedly connected and communicated with the end of the accommodation pipe 6 near the anchor hole 11, and the other end of the oil injection pipe 7 is provided with an oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com