Multi-stage depressed collector with deflection magnetic field

A deflection magnetic field and collector technology, which is applied to collectors, discharge tubes, and electrical components of time-of-flight electron tubes, can solve the problems of electron injection backflow and low heat dissipation efficiency, and achieve simple structure, easy processing, and collection high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the implementation methods and accompanying drawings.

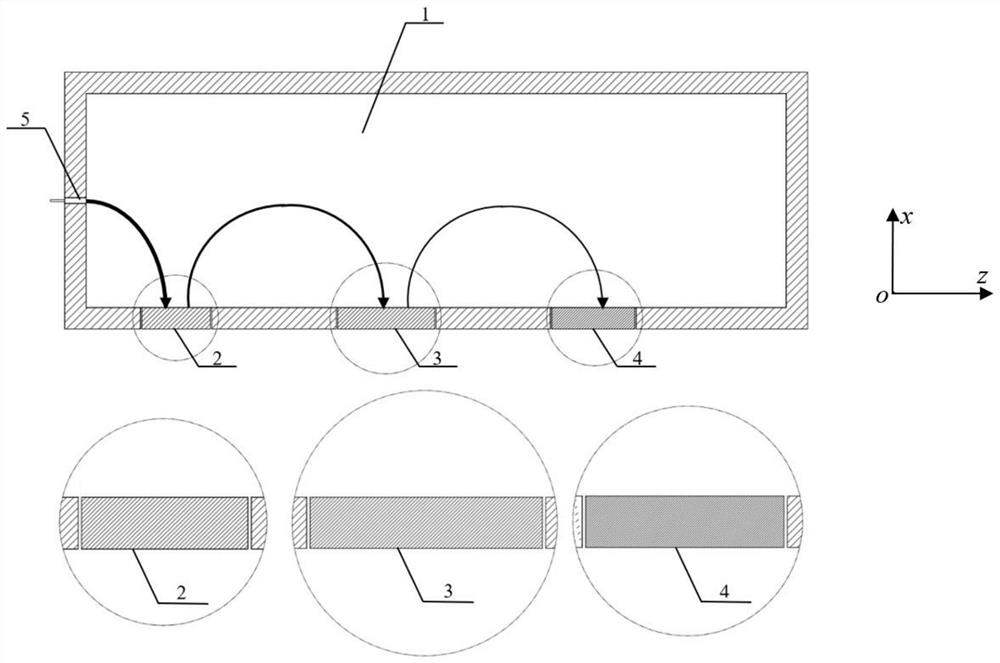

[0030] figure 1 It is a schematic diagram of the working principle of the cross section of the present invention perpendicular to the direction of the inlet electron injection channel. After the interaction of the slow wave structure of the traveling wave tube, the remaining electrons decelerate through the electron beam channel in the first-stage cavity electrode and enter the rectangular cavity. Under the action of the magnetic field, they pass through the second-stage blade electrode and the third-stage blade. The electrodes and the fourth-stage blade electrodes are respectively connected to power supplies of different voltages, and the collected current is fed back to the power supply for reuse. In addition, due to the action of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com