Flexible stretchable zinc-air battery based on foam-based metal electrode and preparation

A zinc-air battery and base metal technology, applied in electrical components, battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, etc. The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of described copper plating / nickel sponge layer comprises the following steps:

[0057] A1. Cut the sponge film into small pieces, and dry them completely after ultrasonic cleaning;

[0058] A2, stick the dried sponge film on the rubber film, then solidify to get the bonded sponge-rubber film;

[0059] A3, put the bonded sponge-rubber film on SnCl 2 Vacuum immerse in hydrochloric acid solution for 10-60min, take it out and put it in PdCl 2 Vacuum immersion in hydrochloric acid solution for 10-60min, take out, and freeze-dry to obtain a surface-activated sponge-rubber film;

[0060] A4, immerse the surface-activated sponge-rubber film in an electroless copper-plating solution or a nickel-plating solution to deposit metallic copper or nickel on the surface to form a copper-plated layer or a nickel-plated layer to obtain a copper-plated nickel sponge layer.

[0061] In step A1, the sponge film is a polyurethane sponge film with a thickness of 0.1-...

Embodiment 1

[0084] This embodiment provides a method for preparing a flexible and stretchable zinc-air battery based on a foam-based metal electrode, including the following steps:

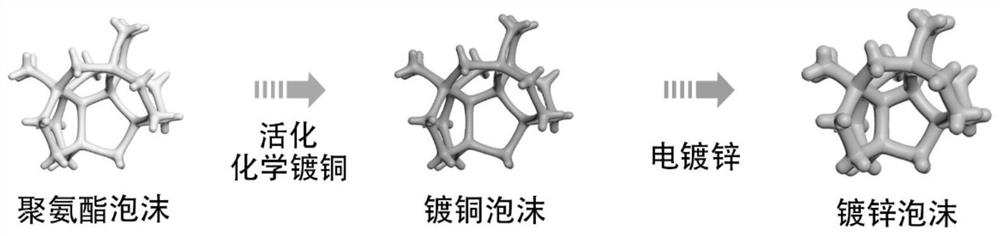

[0085] (1) Preparation of galvanized foam (anode) (such as figure 1 shown):

[0086] 1.1 Mix and stir Ecoflex-0030 silicone rubber A and B liquids at a weight ratio of 1:1 to form Ecoflex precursor liquid, pour Ecoflex precursor liquid into a glass mold with a depth of 1mm, put it in an oven at 60°C for 1 hour, and cross-link and cure to form Ecoflex rubber film.

[0087] 1.2 Cut the commercial polyurethane sponge film (~1mm thick) into small pieces, ultrasonically clean them with acetone, ethanol and deionized water for 10 minutes each, and put them in an oven at 60°C until they are completely dry.

[0088] 1.3 Stick a piece of dried polyurethane sponge film on the Ecoflex rubber film with Ecoflex precursor fluid, and cure at 60°C for 30 minutes. The polyurethane sponge film and the Ecoflex rubber film are...

Embodiment 2

[0103] This embodiment provides a method for preparing a flexible and stretchable zinc-air battery based on a foam-based metal electrode, including the following steps:

[0104] (1) Preparation of galvanized foam (anode):

[0105] 1.1 Mix and stir Ecoflex-0030 silicone rubber A and B liquids at a weight ratio of 1:1 to form Ecoflex precursor liquid, pour Ecoflex precursor liquid into a glass mold with a depth of 1mm, put it in an oven at 60°C for 1 hour, and cross-link and cure to form Ecoflex rubber film.

[0106] 1.2 Cut the commercial polyurethane sponge film (~1mm thick) into small pieces, ultrasonically clean them with acetone, ethanol and deionized water for 10 minutes each, and put them in an oven at 60°C until they are completely dry.

[0107] 1.3 Stick a piece of dried polyurethane sponge film on the Ecoflex rubber film with Ecoflex precursor fluid, and cure at 60°C for 30 minutes. The polyurethane sponge film and the Ecoflex rubber film are tightly bonded together. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com