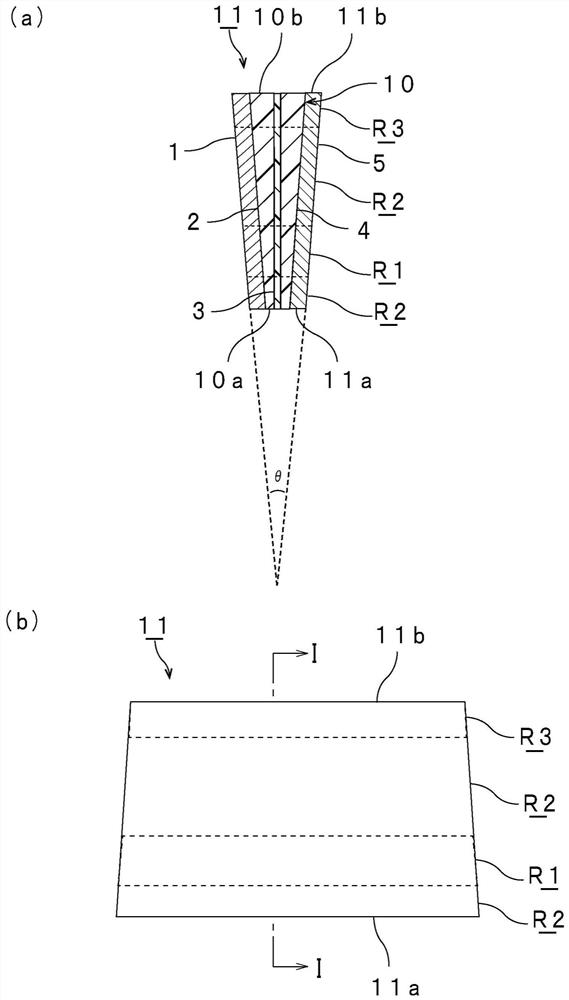

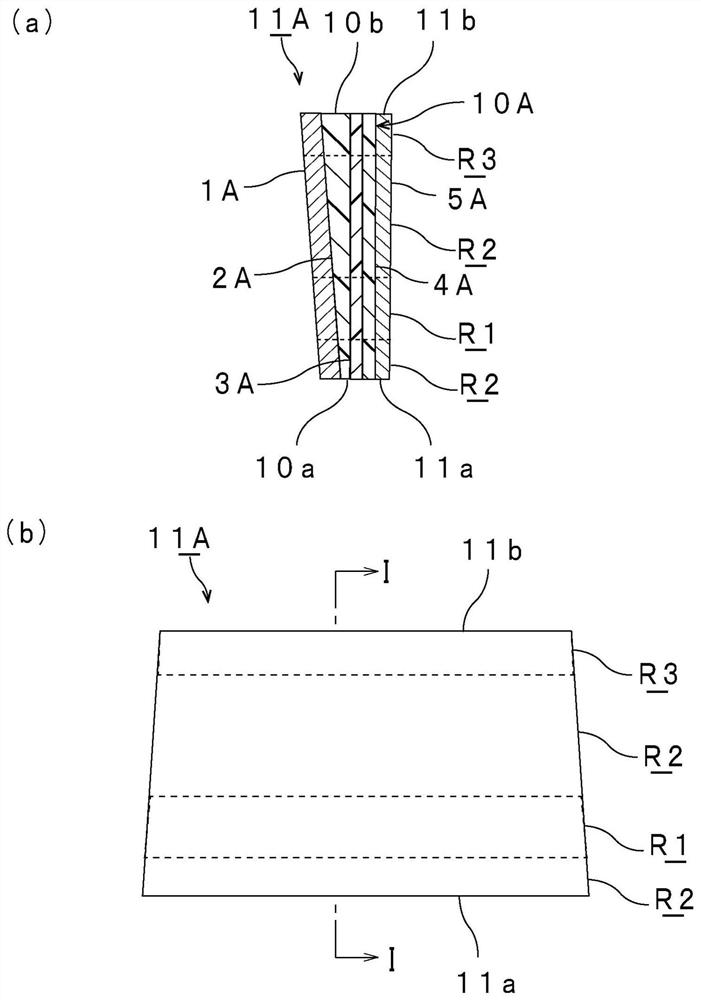

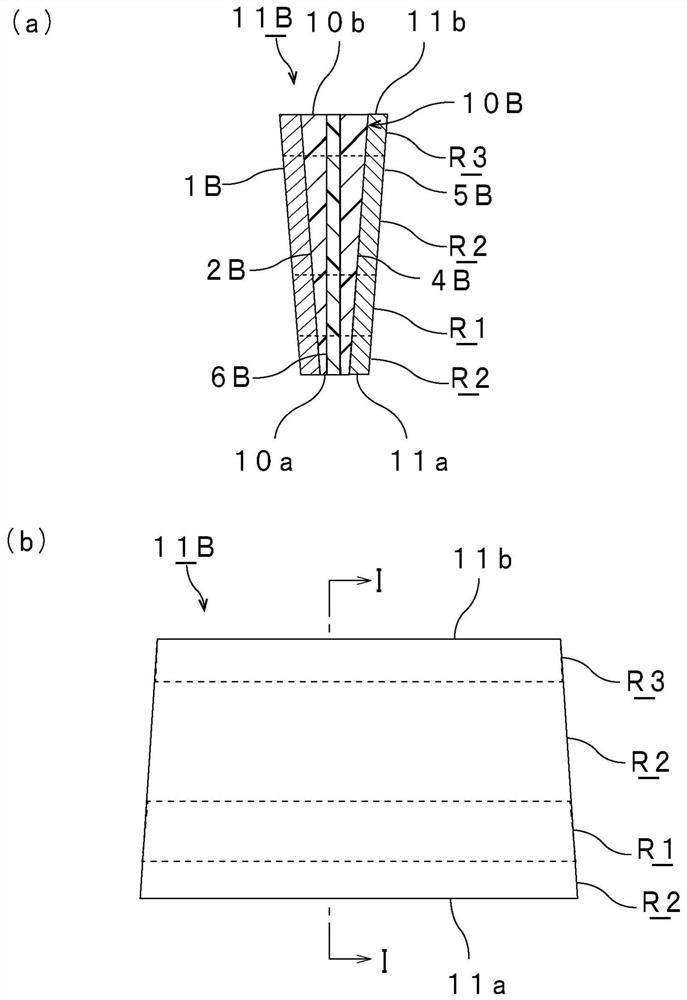

Laminated glass, head up display system, and method for manufacturing head up display system

A technology of laminated glass and head-up display, applied in chemical instruments and methods, windshields, glass/slag layered products, etc., can solve problems such as observed ghosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0337] Preparation of the first resin layer:

[0338] The following components were mixed and fully kneaded with a mixing roll to obtain a composition for forming the first resin layer.

[0339] Polyvinyl acetal resin (average degree of polymerization 1700, hydroxyl content 30.5 mol%, degree of acetylation 1 mol%, degree of acetalization 68.5 mol%) 100 parts by weight

[0340] 40 parts by weight of triethylene glycol di-2-ethylhexanoate (3GO)

[0341] Tinuvin326 (2-(2'-hydroxy-3'-tert-butyl-5-methylphenyl)-5-chlorobenzotriazole, manufactured by BASF Corporation in an amount of 0.2% by weight in the obtained resin layer Tinuvin326")

[0342] BHT (2,6-di-t-butyl-p-cresol) in an amount of 0.2% by weight in the obtained resin layer

[0343] The obtained composition for forming the first resin layer was extruded using an extruder to obtain a first resin layer having the thickness and wedge angle shown in Table 1 below.

[0344] Preparation of the second resin layer:

[0345] T...

Embodiment 2~15 and comparative example 1~19

[0359] Laminated glass was obtained in the same manner as in Example 1, except that the configuration of the interlayer film was changed as shown in Tables 1 to 6 below.

[0360] In Comparative Examples 1 to 11 and 15 to 17, no infrared reflection layer was used.

[0361] It should be noted that, in Examples 2 to 15 and Comparative Examples 1 to 19, in the first and second resin layers, the same ultraviolet shielding agent and antioxidant as in Example 1 were used in 100% by weight of the obtained resin layer. The same mixing amount as in Example 1 was mixed. The heat-shielding substance was mixed in the compounding quantity shown to the following Tables 1-6 with respect to 100 weight% of the obtained resin layer. In addition, in Examples 8 to 15 and Comparative Examples 15 to 19, the light emitting material in the amount indicated in the table was used in the obtained resin layer.

[0362] (Evaluation)

[0363] (1) Sunlight transmittance

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com