Particle size crushing and screening equipment for feed

A technology of particle size and screening equipment, applied in the direction of feed, sieve, application, etc., can solve the problem of feeding small feed and cutting, and achieve the effect of improving quality, saving consumption and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

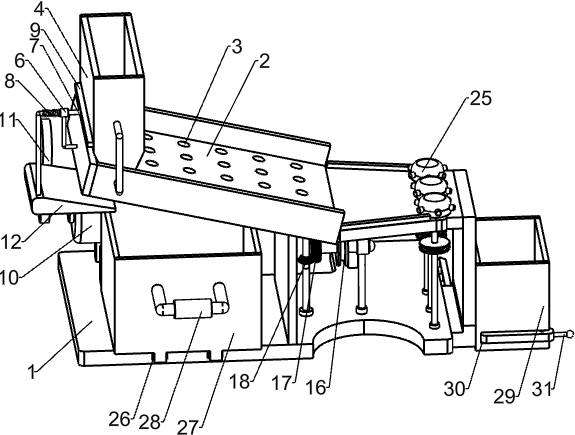

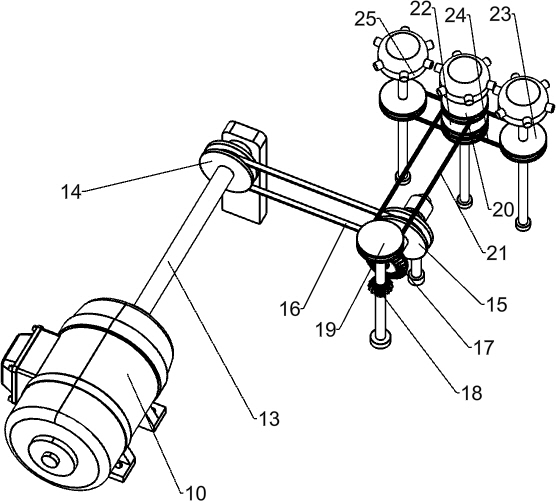

[0021] A particle size crushing and screening equipment for feed, such as Figure 1-4 As shown, it includes a base plate 1, a blanking assembly, a drive assembly, a crushing assembly, and a collection assembly. The base plate 1 is used to install the entire device. A drive assembly is welded and powered by a motor. A crushing assembly is welded on the left side of the top of the bottom plate 1 for crushing by rotation. The bottom plate 1 is provided with a collection assembly for collecting feed.

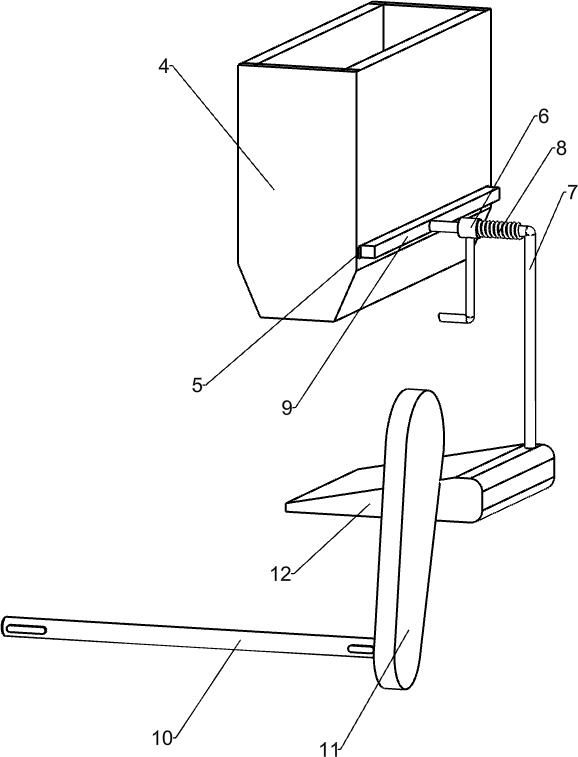

[0022] Such as Figure 1-3 As shown, the blanking assembly includes a slant plate 2, a material storage box 4, a first sliding sleeve 6, an L-shaped sliding rod 7, a first spring 8 and a baffle 9, and the top of the bottom plate 1 is welded with a slant plate 2, and the slant plate 2 There is a blanking hole 3 on the top, a material storage box 4 is welded on the right side of the sloping plate 2, a word hole 5 is opened on the lower part of the right side of the material storage b...

Embodiment 2

[0032] On the basis of Example 1, such as image 3 Shown, also include fork 31, the second collection frame 29 rear side bottoms have through hole 30, the second collection frame 29 rear side bottoms are rotatably provided with fork 31, fork 31 cooperates with through hole 30.

[0033] On the basis of embodiment 1-2, such as figure 1 As shown, it also includes a second sliding sleeve 32, a knock rod 33, a second spring 34, a contact plate 35 and a push rod 36, the middle part of the right side of the swash plate 2 is welded with a second sliding sleeve 32, and the second sliding sleeve 32 The sliding type is provided with a knocking rod 33, a second spring 34 is connected between the knocking rod 33 and the second sliding sleeve 32, a contact plate 35 is welded at the bottom of the knocking rod 33, and a push rod 36 is welded at the middle of the rotating rod 13 , The push rod 36 cooperates with the contact plate 35 .

[0034] The specific operation process of the above embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com