Electroplating wastewater treatment process

A technology for treating process and electroplating wastewater, which is applied in metallurgical wastewater treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problems of low impurity removal efficiency and cumbersome procedures, and achieve good flocculation, simple operation procedures, The effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

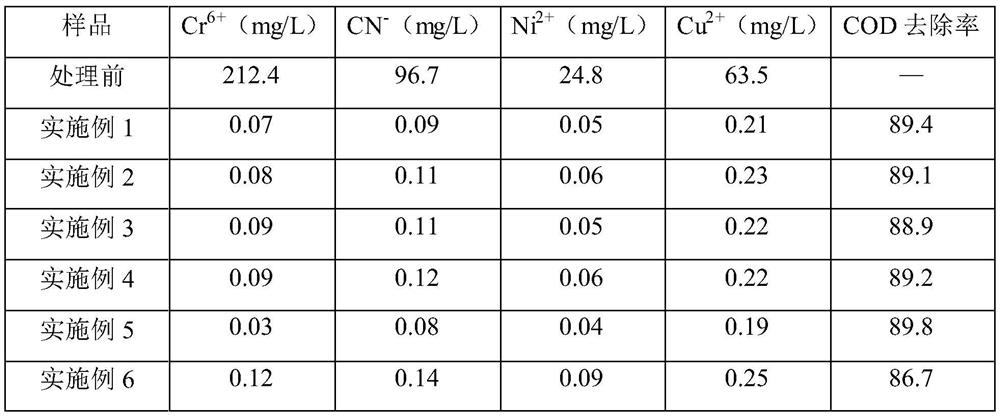

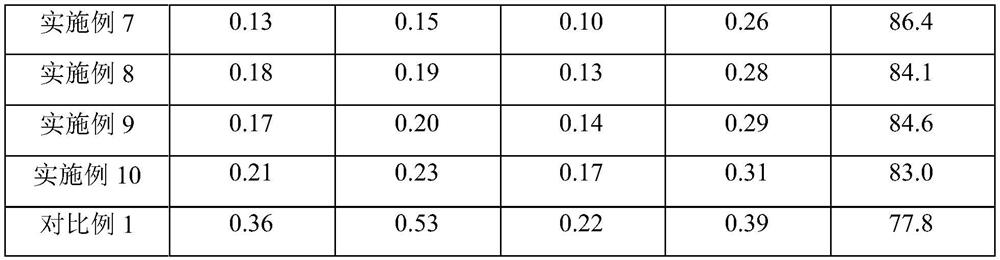

Examples

Embodiment 1

[0038] A treatment process for electroplating wastewater, specifically comprising the following treatment steps:

[0039] S1. Pre-treat the cyanide-containing electrochrome plating wastewater, and sequentially feed the wastewater into the degreasing tank and filter tank to remove the slick oil and impurities in the wastewater;

[0040] S2. Feed the wastewater into the regulating tank, and add dilute H into the regulating tank through the dosing system2 SO 4 The solution adjusts the pH value of the wastewater to 3;

[0041] S3. Feed the wastewater into the Fenton reaction tank, and add FeSO to the Fenton reaction tank through the dosing system 4 , after reacting for 15min, add 25% H 2 o 2 solution, H 2 o 2 with Fe 2+ The molar ratio is 8:1, and the residence time of the wastewater in the Fenton reaction tank is 50min;

[0042] S4. Feed the waste water into the flocculation tank 1, add polyphosphorus ferric chloride into the flocculation tank 1 through the dosing system, ...

Embodiment 2

[0051] A treatment process for electroplating wastewater, specifically comprising the following treatment steps:

[0052] S1. Pre-treat the cyanide-containing electrochrome plating wastewater, and sequentially feed the wastewater into the degreasing tank and filter tank to remove the slick oil and impurities in the wastewater;

[0053] S2. Feed the wastewater into the regulating tank, and add dilute H into the regulating tank through the dosing system 2 SO 4 The solution adjusts the pH value of the wastewater to 2;

[0054] S3. Feed the wastewater into the Fenton reaction tank, and add FeSO to the Fenton reaction tank through the dosing system 4 , after reacting for 15min, add 25% H 2 o 2 solution, H 2 o 2 with Fe 2+ The molar ratio is 6:1, and the residence time of the wastewater in the Fenton reaction tank is 40min;

[0055] S4. Feed the waste water into the flocculation tank 1, add polyphosphorus ferric chloride into the flocculation tank 1 through the dosing system...

Embodiment 3

[0064] A treatment process for electroplating wastewater, specifically comprising the following treatment steps:

[0065] S1. Pre-treat the cyanide-containing electrochrome plating wastewater, and sequentially feed the wastewater into the degreasing tank and filter tank to remove the slick oil and impurities in the wastewater;

[0066] S2. Feed the wastewater into the regulating tank, and add dilute H into the regulating tank through the dosing system 2 SO 4 The solution adjusts the pH value of the wastewater to 3.5;

[0067] S3. Feed the wastewater into the Fenton reaction tank, and add FeSO to the Fenton reaction tank through the dosing system 4 , after reacting for 15min, add 25% H 2 o 2 solution, H 2 o 2 with Fe 2+ The mol ratio is 10:1, and the residence time of waste water in the Fenton reaction tank is 60min;

[0068] S4. Feed the waste water into the flocculation tank 1, add polyphosphorus ferric chloride into the flocculation tank 1 through the dosing system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com