Automatic electroplating production process

A technology of production process and electroplating box, which is applied in the field of automated electroplating production process, can solve the problems of low degree of automation, achieve the effect of high degree of automation, improve surface finish, and reduce manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The automated electroplating production process includes the following steps:

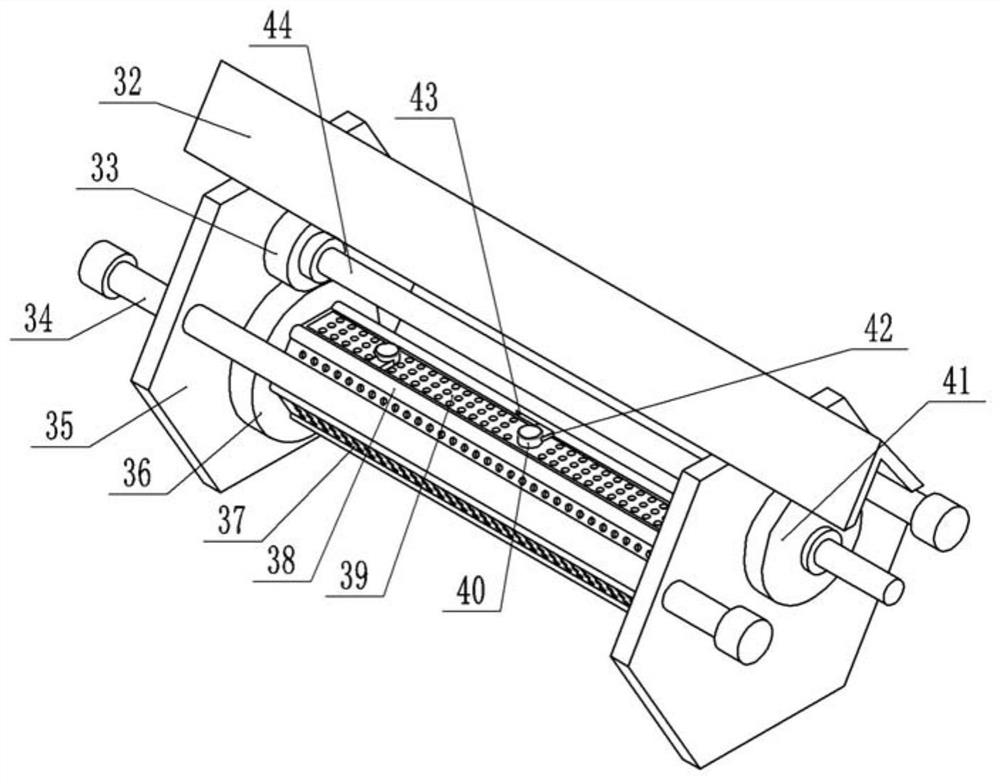

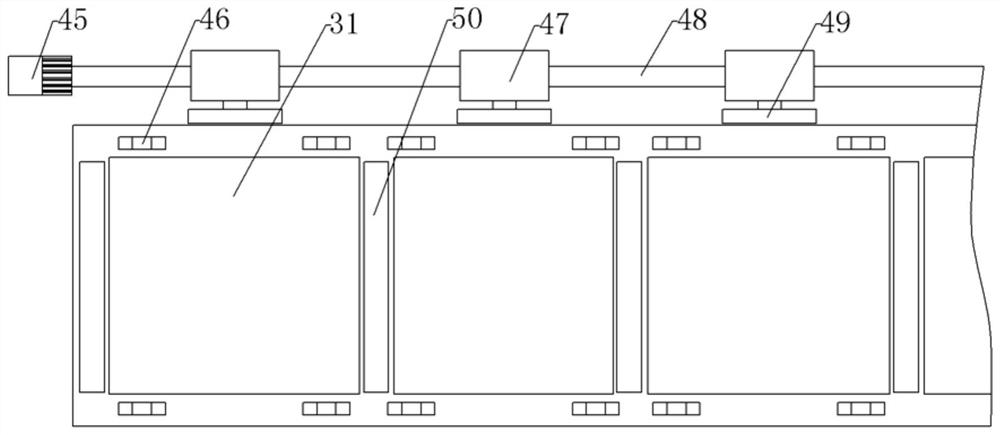

[0040] S1: put the workpiece into the grinding machine for grinding, the grinding machine in this embodiment adopts the vibration type grinding machine in the prior art; the workpiece after grinding is put into such as figure 2 shown in the electroplating box, and then transported to the treatment pool 31 for a water wash, and the first water wash adopts three-stage countercurrent water wash;

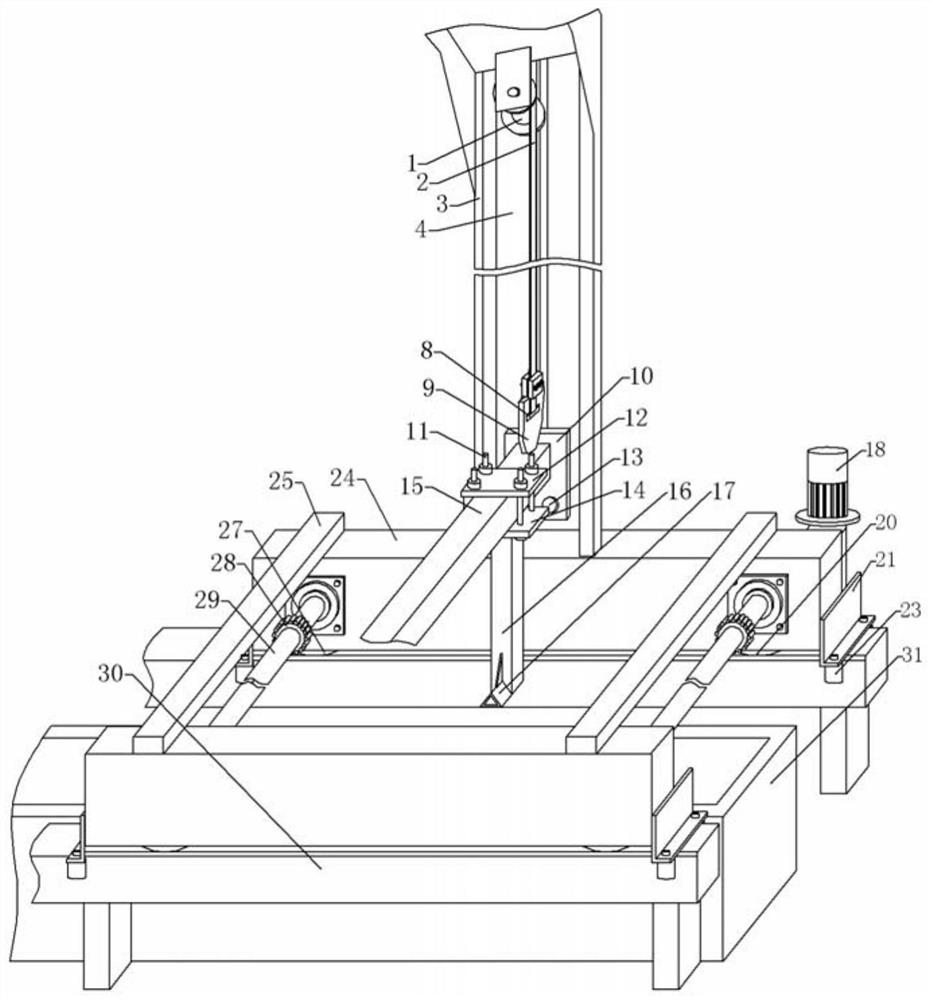

[0041] S2: Using as figure 1 The crane 24 shown transports the workpieces washed once to different treatment tanks 31 for pickling, second washing, activation, third washing, electroless nickel plating, spray washing, passivation, pure water washing, and hot pure water washing. , wherein the second washing is the second-level countercurrent washing, the third washing is the third-level counter-current washing, and the pure water washing is the second-level counter-current pure water washing;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com