Intelligent water hammer eliminating tank system and use method

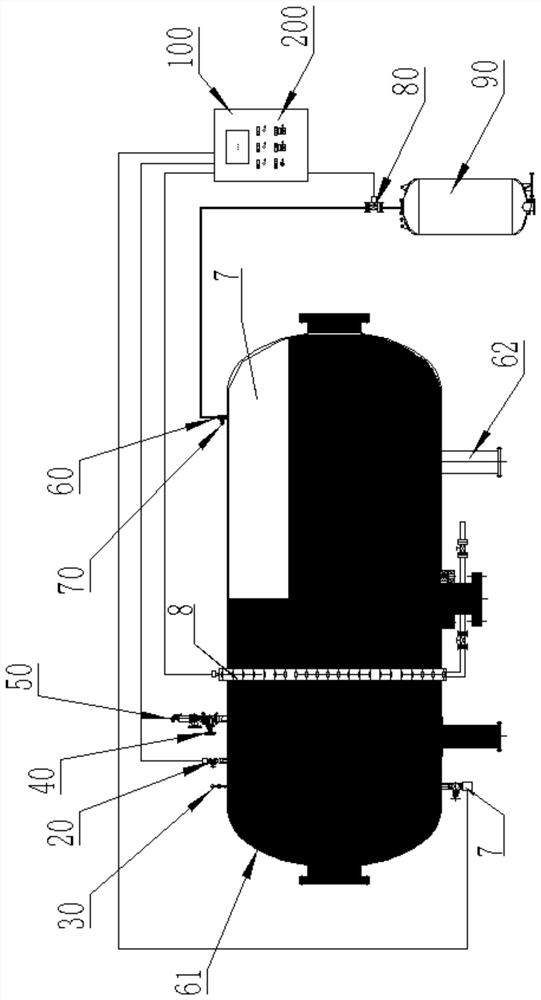

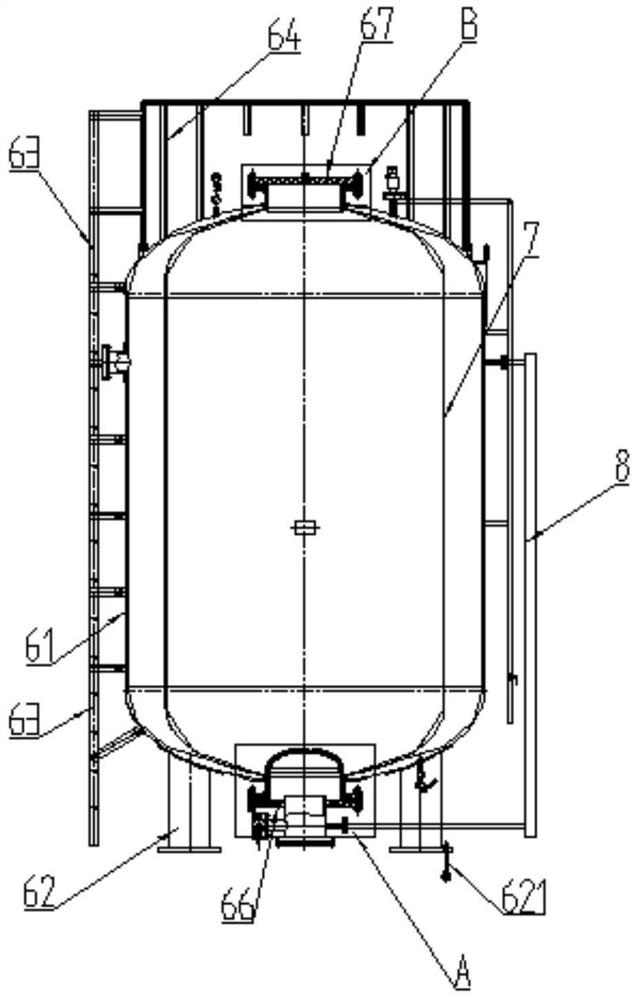

A water hammer and intelligent technology, applied in the field of pipeline transportation equipment, can solve the problems that the water hammer elimination tank does not have parameter state detection and protection, and the vertical and horizontal water hammer elimination tanks do not have intelligent control functions, so as to prevent shutdown Pump water hammer, prevent bridging water hammer, simple body structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

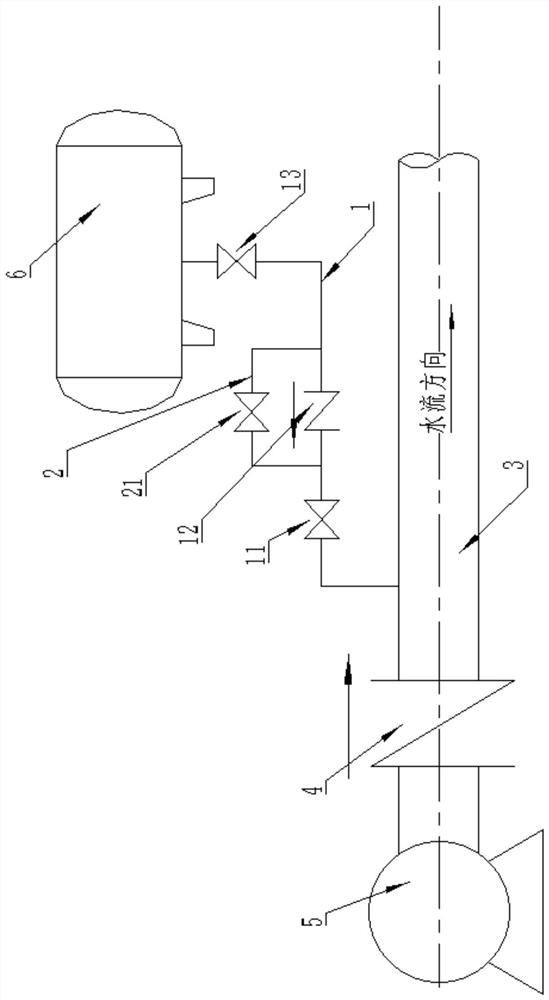

[0083] Implementation plan: when the water pump 5 is turned on and the pipeline starts to feed water into the liner type water hammer elimination tank 6, record the corresponding data of pressure and liquid level and draw it into a curve, and draw a set value, such as Figure 8 90% curve of (actual pressure and volume product value), as shown by line B in Figure 8 As shown in the A line, when the actual liquid level is higher than the red line under the corresponding pressure, an alarm signal will be sent.

[0084] S3. Real-time monitoring during operation and judgment on whether to supplement gas. According to the judgment result, whether to supplement gas is performed. The pressure of the pre-charged compressed gas is set to P1, the volume of the water hammer elimination tank is V1, and the gas pressure is P2 during operation. The volume of compressed gas is V2 when working;

[0085] V1 is the input of known initialization parameters, and P1 and P2 are collected by pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com