Control device and method for gas pressure in silver slurry curing oven

A gas pressure and control device technology, which is applied in the direction of drying gas arrangement, liquid coating device on the surface, drying, etc., can solve the problems of easy oxidation and corrosion of internal equipment, low bonding strength, etc., and achieve convenient process adjustment and control , reduce contamination, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

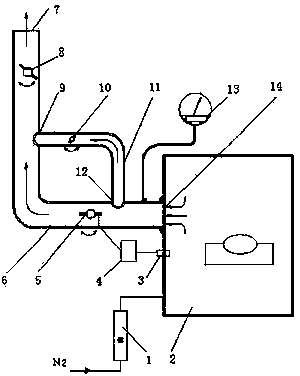

[0033] Such as figure 1 The gas pressure control device in the silver paste curing oven is composed of main exhaust duct 6, auxiliary exhaust duct 11, micro-pressure measuring gauge 13, oven 2, pneumatic automatic damper 5, manual negative pressure regulating valve 8, manual positive pressure regulating Valve 10, micro pressure gauge 13, temperature sensor 3, automatic control device 4 and other components.

[0034] The air outlet 7 of the main exhaust duct is connected to the exhaust fan, and the oven 2 is connected to the N 2 The gas source 1 is used as an inert protective gas in the oven 2. The oven 2 is connected to the air inlet 14 of the main exhaust duct, and the main exhaust duct 6 is connected to the air inlet 12 of the auxiliary exhaust duct and the air outlet 9 of the auxiliary exhaust duct.

[0035] A pneumatic automatic damper 5 is arranged in the main air duct 6 between the air inlet 12 of the auxiliary air duct and the air outlet 9 of the auxiliary air duct, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com