Anti-blocking heat exchanger

A technology for heat exchangers and anti-clogging, which is applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. Can not be dismantled and other problems, to achieve the effect of easy cleaning and maintenance, improve heat exchange efficiency, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

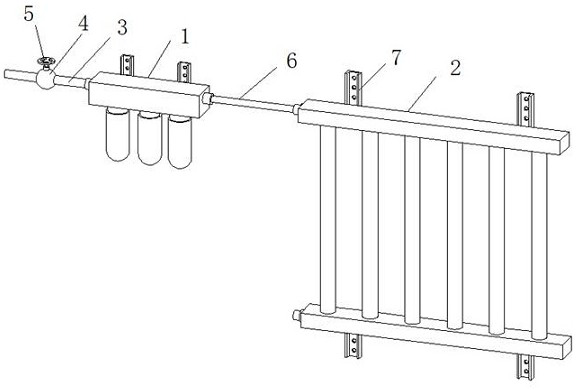

[0035] An anti-clogging heat exchanger such as figure 1As shown, it includes a three-stage filter 1 and a heat exchanger body 2. The left end of the three-stage filter 1 is connected with a liquid inlet metal pipe 3, and a control valve 4 is installed on the liquid inlet metal pipe 3. The top of the control valve 4 is provided with a flow rate Adjust the switch 5, the right end of the three-stage filter 1 is connected with a liquid metal pipe 6, and the liquid metal pipe 6 is connected with the heat exchanger body 2; the rear side walls of the three-stage filter 1 and the heat exchanger body 2 are fixed There is a mounting frame 7, and a fixing hole is provided on the mounting frame 7. The setting of the mounting frame 7 facilitates fixing the three-stage filter 1 and the heat exchanger body 2 on the wall or other frames.

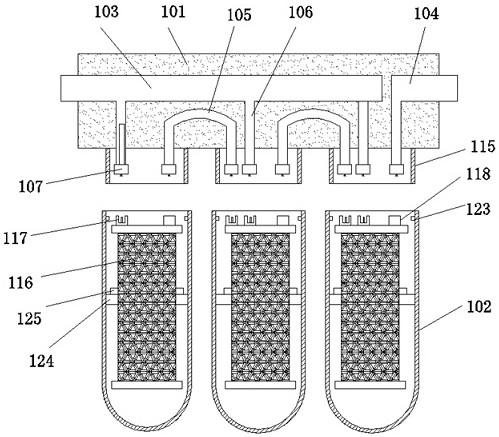

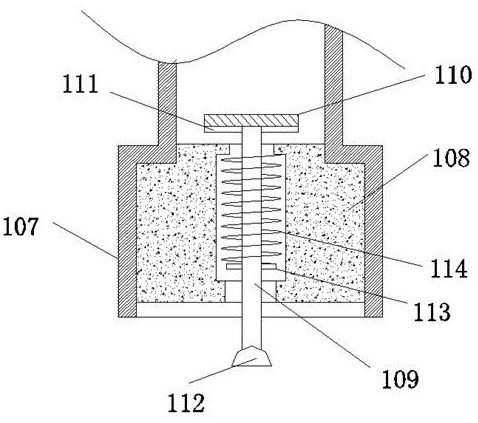

[0036] Among them, such as Figure 2-6 As shown, the three-stage filter 1 includes a top base 101 and a filter pipe 102. A liquid inlet main pipe 103, a l...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 8 As shown, the heat exchanger body 2 includes a liquid inlet manifold 201 and a liquid outlet manifold 202, and there are several guide pipes 203 arranged at equal intervals in communication between the liquid inlet manifold 201 and the liquid outlet manifold 202. The left side wall of the pipe 201 is equipped with a liquid inlet connector 204, and the left side wall of the liquid outlet manifold 202 is equipped with a liquid outlet connector 205; the downstream of the liquid outlet connector 205 is connected with a recovery container 207 through a liquid outlet hose 206, The side wall of the recovery container 207 is connected with a recovery pipe 209 and a recoil pipe 208, and the liquid outlet end of the recoil pipe 208 is connected with three recoil branch pipes 210, and the bottom ends of the three recoil branch pipes 210 respectively pass through the top seat 101 and extend into the To the inside of the three filter tube...

Embodiment 3

[0044] On the basis of Example 2, such as Figure 9 with Figure 10 As shown, the heat exchanger body 2 includes a liquid inlet manifold 201 and a liquid outlet manifold 202, and there are several equal-spaced guide tubes 203 connected between the liquid inlet manifold 201 and the liquid outlet manifold 202; the guide tubes The outer wall of 203 is provided with annular mounting groove 215, and the outer wall of annular mounting groove 215 is sleeved with a pair of arc-shaped pieces 216, and the pair of arc-shaped pieces 216 are fixed and installed by bolts, and the outer walls of a pair of arc-shaped pieces 216 are integrated There are cooling fins 217 fixed therein.

[0045] When this embodiment is in use, a pair of bolts can be used to fix the arc-shaped piece 216 on the outer wall of the annular installation groove 215, and the heat dissipation fins 217 integrally fixed on the outer wall of the arc-shaped piece 216 can increase the heat dissipation area, thereby improving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com