An open experimental device and method for simulating single-slug plugging removal process

An experimental device and process technology, applied in the direction of measuring device, chemical method analysis, weighing by removing certain components, etc., can solve the problems of complex experiments, large differences in clogging degree, long experimental cycle, etc., and achieve experimental repetition Good performance, reduce human error, and short experiment period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

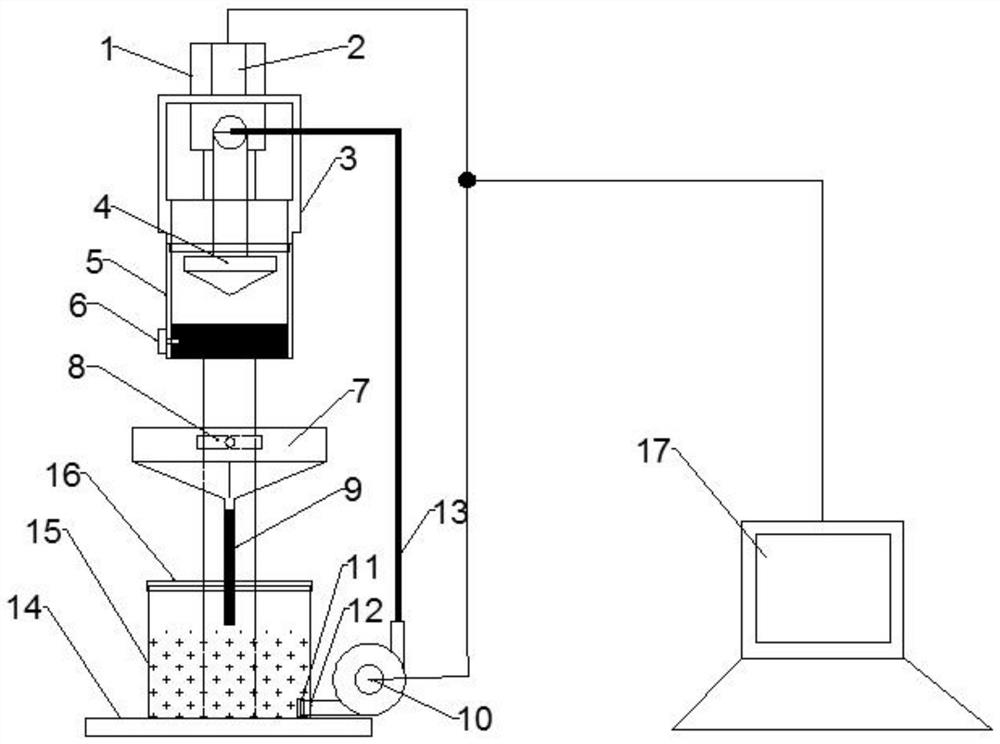

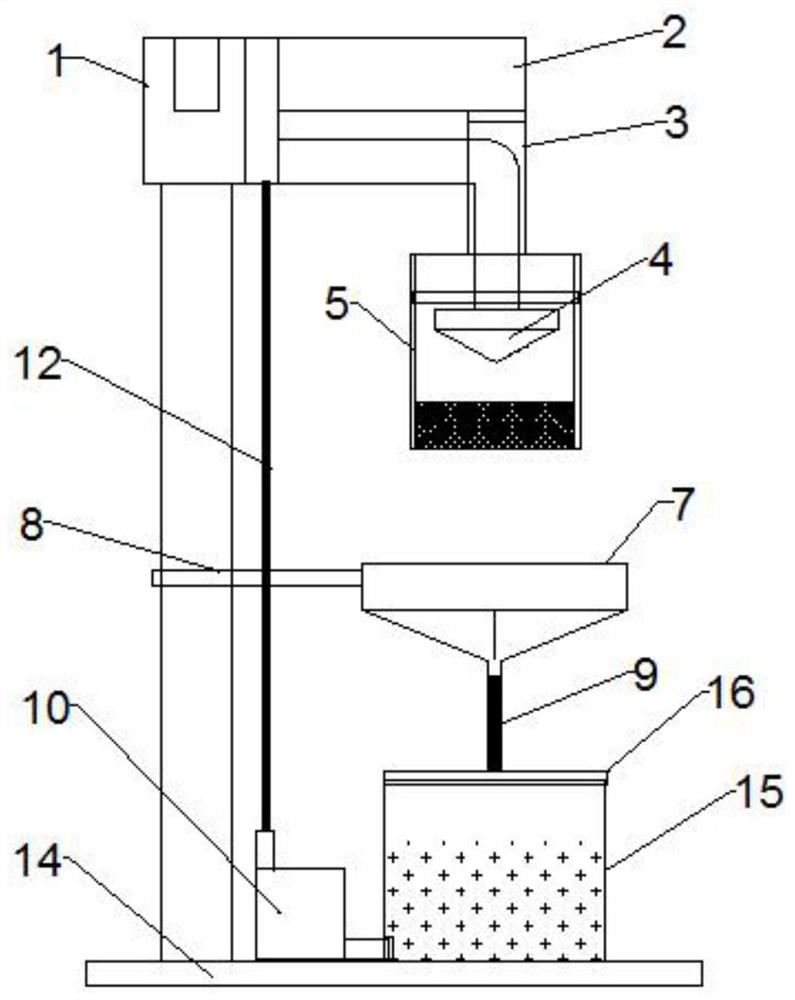

[0084] The single-node blockage circulation flushing simulation method is used to optimize the type of plugging agent and parallel experiments. The operation methods are as follows:

[0085] Step 1: Connect the outlet of the liquid supply pump 10 to the flushing nozzle 4, and connect the outlet of the liquid collecting funnel 7 to the constant temperature tank 15;

[0086] Step 2: The constant temperature tank 15 is loaded with a plugging remover; the plugging remover is 600 g of ammonium persulfate prepared with a concentration of 1%; the temperature is set to the downhole plugging removal temperature of 60°C;

[0087] Step 3: The measuring cup 5 is fixed on the measuring cup fixing frame 3, the control device 17 controls the mass sensor 2 to clear the zero; the measuring cup 5 is removed, the blockage 52 is inserted, and the mass m at this time is recorded 0 =150.825g; fix the measuring cup 5 on the measuring cup holder 3;

[0088] Step 4: The flow rate of the liquid supply...

Embodiment 2

[0096] The existing soaking and dissolving experimental methods (such as the method in "SZ36-1 Oilfield Polymer Injection Well / Production Well Plug Removal Technology Research") are used to compare with the method of the present invention. The process of the method of the present invention is as in Example 1.

[0097] The existing methods are as follows:

[0098] Step 1: Prepare a threaded bottle according to the experimental requirements, weigh a certain amount of polymer injection well and record it as w 1 ;

[0099] Step 2: prepare ammonium persulfate (APS) with a concentration of 1%, and mix the ammonium persulfate and the polymer injection well rebate in a mass ratio of 4:1;

[0100] Step 3: static reaction at 60°C for 24h;

[0101] Step 4: Test the quality of the polymer injection well after the reaction 2 ;

[0102] Step 5: Calculate the corrosion rate of the return material, and the calculation formula is β=(w 1 -w 2 ) / w 1 ×100%

[0103] Step 6: The experiment...

Embodiment 3

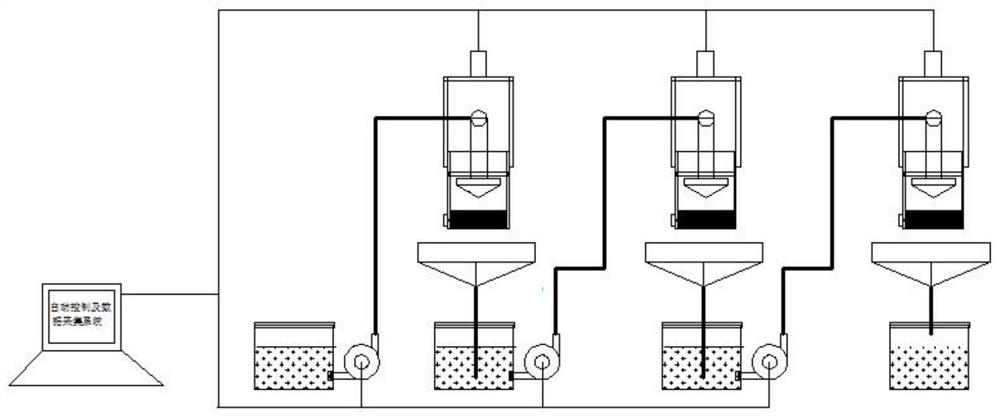

[0108] The multi-node blockage series continuous flushing plugging removal simulation experiment method is used to simulate the continuous plugging removal effect evaluation on site. The blockages at different nodes use the backflow materials of different flowback volumes from the injection well. The process is as follows:

[0109] Step 1: Determine the number of series units to be 3, connect the outlet of the liquid supply pump 10 of each node to the flushing nozzle 4; the outlet of the liquid collecting funnel 7 of the previous node is connected to the constant temperature tank 15 of the next node;

[0110] Step 2: The first constant temperature tank 15 is filled with a blocking agent; the blocking agent is selected to be 1% sodium percarbonate, and the temperature of the constant temperature tank 15 is set to be 60°C for the downhole blocking removal operation temperature;

[0111] Step 3: Each measuring cup 5 is fixed on the measuring cup fixing frame 3, and the control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com