Method for predicting dynamic re-crystallization fraction of Nb microalloyed steel

A technology of micro-alloy steel and recrystallization, which is applied in the interdisciplinary field of steel research and machine learning, can solve the problems of low accuracy of model parameters, long simulation time, and a large number of thermal simulations, so as to achieve wide applicability, reduce workload, and reduce The effect of single-pass compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

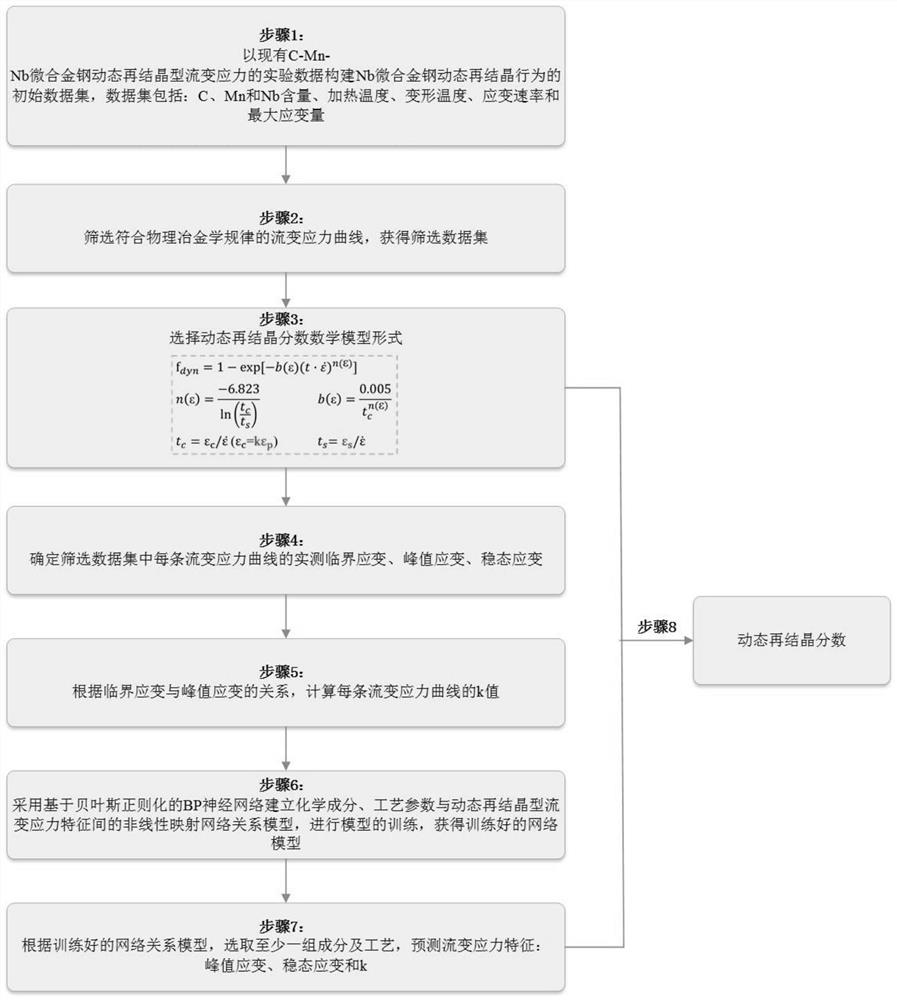

[0032] The method for predicting the dynamic recrystallization fraction of Nb microalloyed steel, the flow chart is as follows figure 1 shown, including the following steps:

[0033] Step 1. Construct the initial data set of dynamic recrystallization behavior of Nb microalloyed steel with the experimental data of 410 existing C-Mn-Nb microalloyed steel dynamic recrystallization flow stress curves. The data set includes: C, Mn and Nb content, heating temperature, deformation temperature, strain rate and maximum strain;

[0034] Step 2. Screen the flow stress curves conforming to the laws of physical metallurgy. The screening criteria are: ① judge whether the flow stress curve conforms to the laws of physical metallurgy under different deformation conditions of the same composition. For example, under the conditions of different deformation temperatures of the same composition, as the deformation temperature decreases, the flow stress increases gradually at the same strain; und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com