Production process of high-voltage-resistant connecting wire

A technology of high-voltage resistance and connecting wires, which is applied to bendable conductors, bendable cables, conductors, etc., can solve the problems of connecting wires being flammable and easy to break in high-temperature environments, and poor heat dissipation performance, so as to increase deformation flexibility, Good insulation effect, effect of increasing inner surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

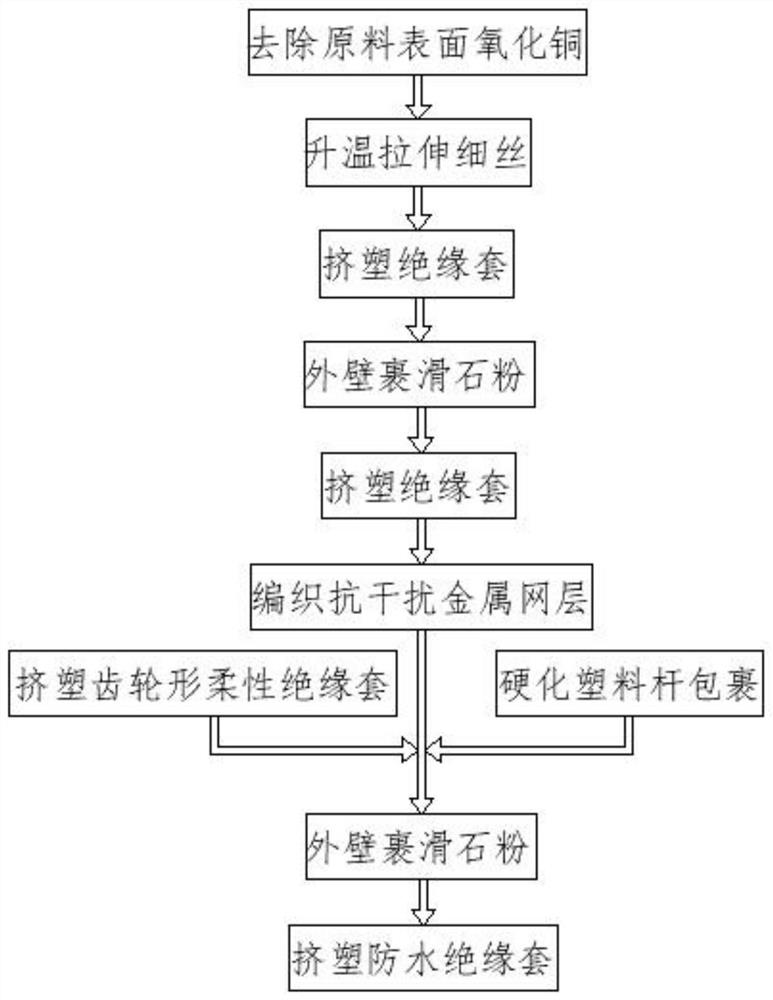

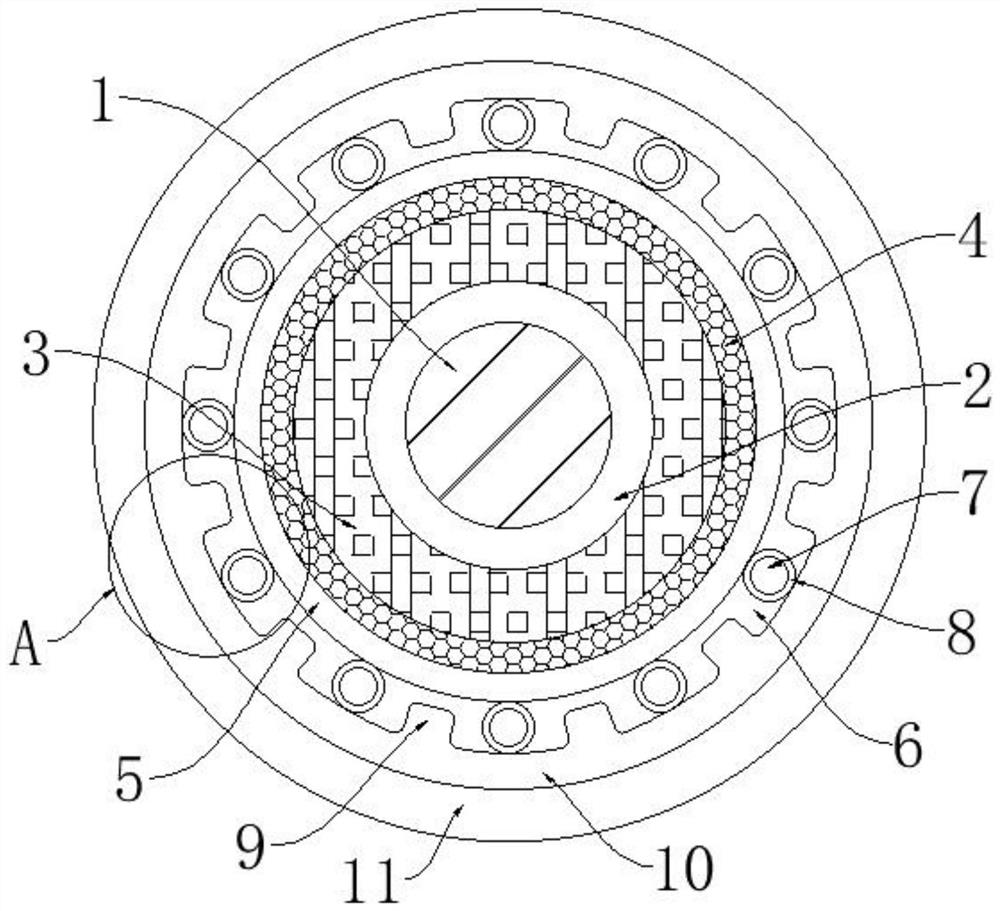

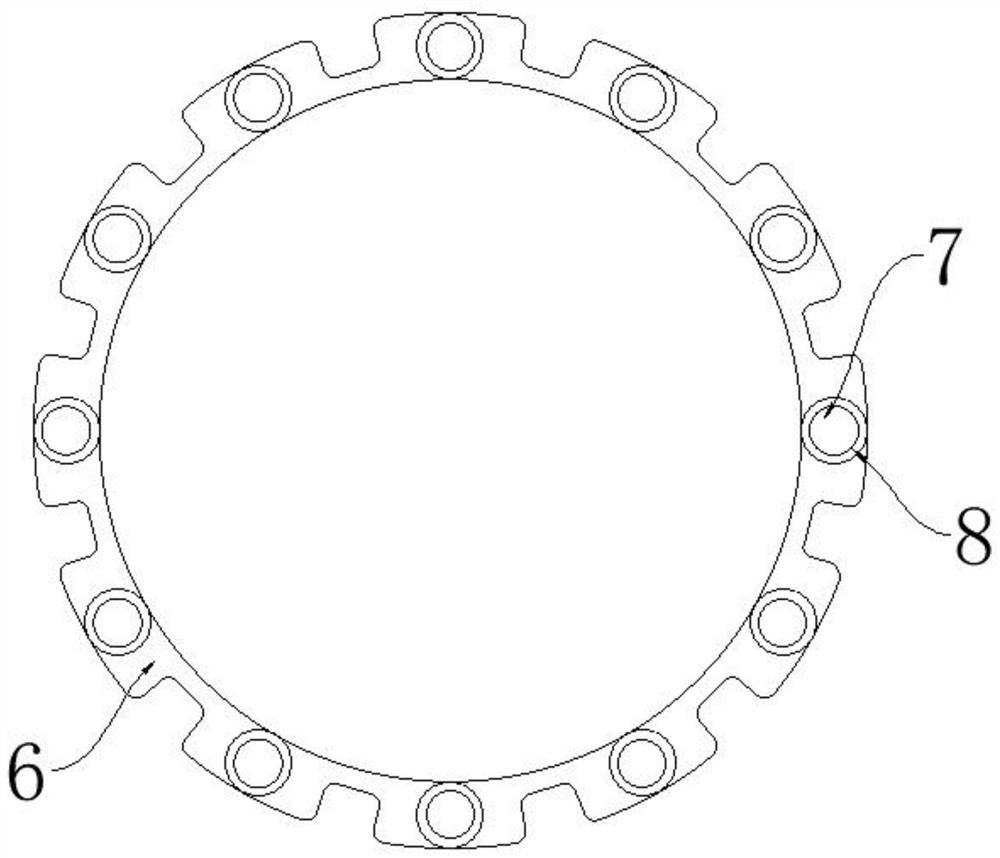

[0035] See Figure 1-5 , The present invention provides an embodiment: a production process for high-voltage connection wires, which includes a surface-removing copper core 1, the outer wall of the surface-removing copper core 1 is provided with an insulating sleeve 2, and the outer wall of the insulating sleeve 2 is provided with a first A talc powder layer 3, the outer wall of the first talc powder layer 3 is provided with a second insulating sleeve 4, the outer wall of the second insulating sleeve 4 is provided with an anti-interference metal mesh layer 5, and the outer wall of the anti-interference metal mesh layer 5 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com