Lath type carbon dioxide glass tube laser

A technology of carbon dioxide and lasers, applied in lasers, laser parts, laser parts, etc., to reduce production costs, maintain stability, and increase discharge volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

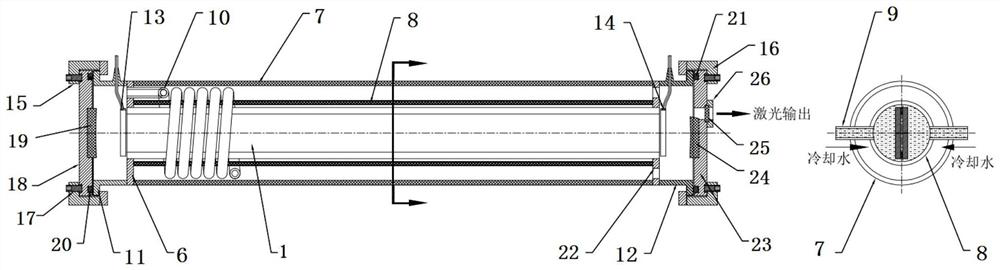

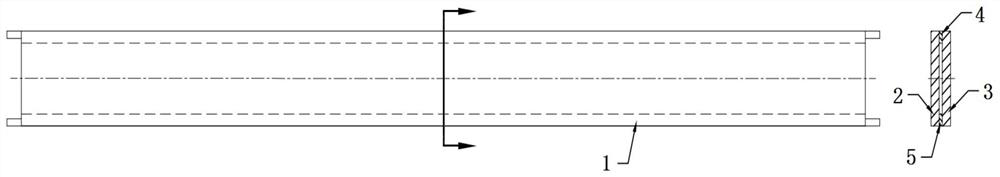

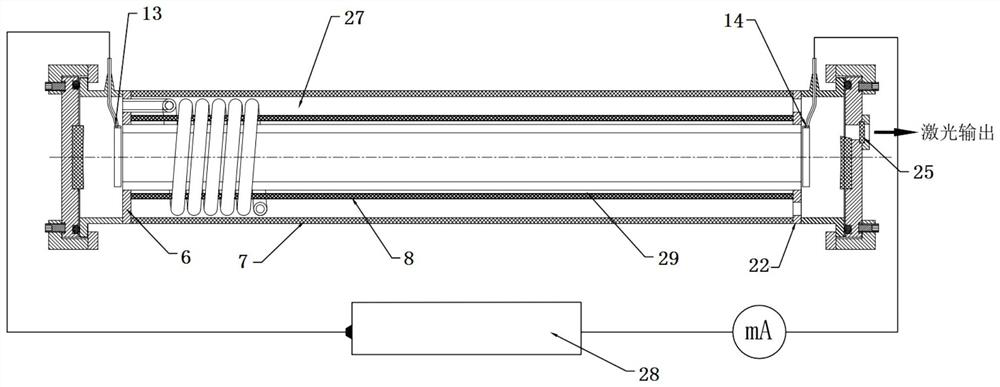

[0028] Such as figure 1 As shown, a slab-type carbon dioxide glass tube laser includes a core discharge chamber 1, the core discharge chamber 1 is successively covered by an inner glass tube 8 and an outer glass tube 7, and the left end of the core discharge chamber 1 is connected from the return gas disc The center of 6 passes through and is welded together, and outer glass tube 7, inner glass tube 8 are installed on the right side of return air disc 6 and are coaxial with return air disc 6, outer glass tube 7 and inner glass tube 8 are equipped with The water pipe 9 and the air return pipe 10 are set on the outside of the inner glass tube 8, and one end is welded to the air return disc 6; the first end face flange 11 and the positive discharge electrode 13 are installed on the right side of the return air disc 6, and the first end face method The outer side of the flange 11 is equipped with a first locking end cover 15, and the adjusting set screw 17 on the first locking end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com