Articulated engineering machinery, panoramic look-around system and calibration method thereof

A technology for construction machinery and panoramic surround view, which is applied in control devices, transportation and packaging, and vehicle parts, etc. It can solve the problems of limited high field of vision in the cab, increased operational difficulty, and blind spots in the driver's field of vision, and achieves the effect of easy image splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

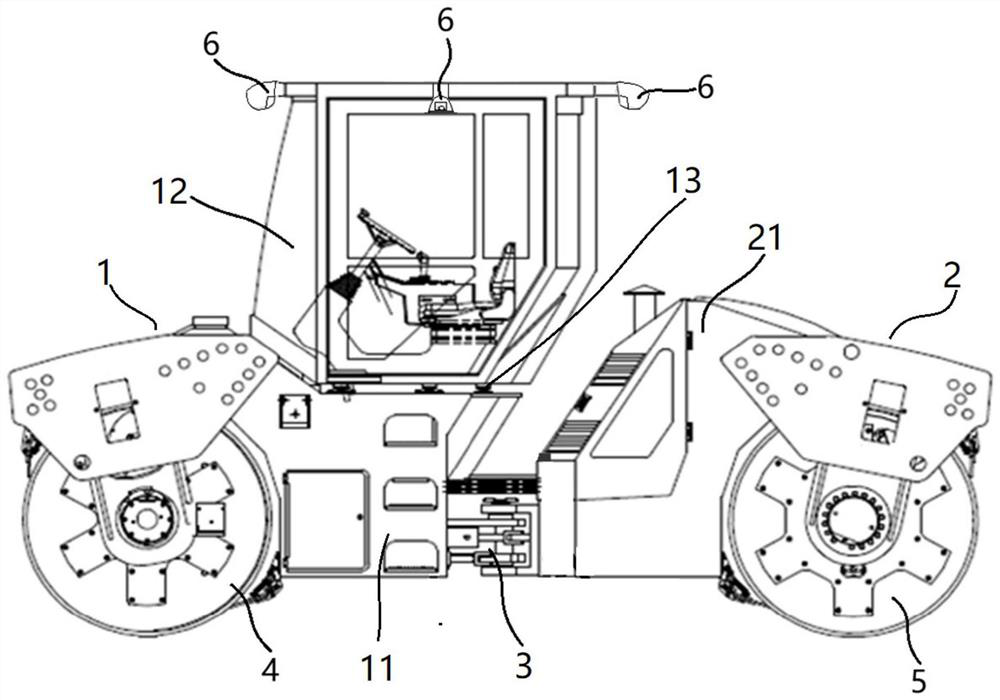

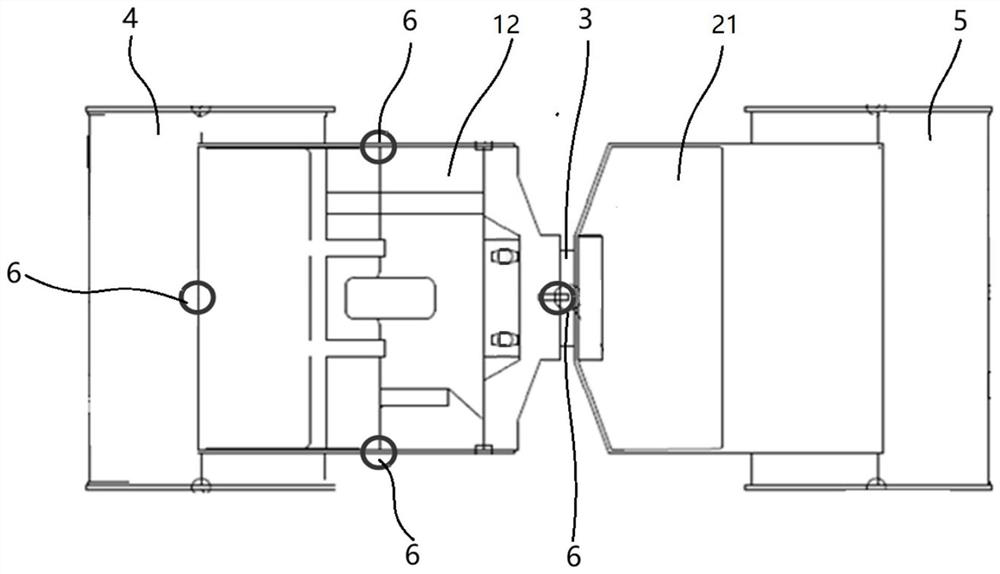

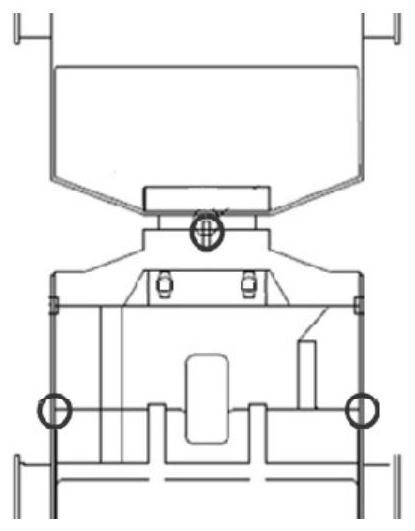

[0116] For the first embodiment, such as Figure 3A to Figure 3D As shown, the four shooting components 6 are all arranged on the cab 12, and four calibration devices 7 are arranged on the reference plane outside the preset reference frame K. The specific method is as follows:

[0117] 1. If Figure 3A , to obtain the overall top view model of the articulated construction machinery;

[0118] 2. If Figure 3B , only keep the partial model of the area where the outline of the cab 12 is kept in the overall top view model, and the outline of the cab 12 refers to the actual outer edge of the cab 12;

[0119] 3. If Figure 3C , find the actual area corresponding to the part of the model in the actual vehicle body, and offset the preset distance L outward relative to the actual area, mark the preset reference frame K on the reference plane, and the preset reference frame K is a rectangle;

[0120] 4. If Figure 3D , the length of the first articulated structure section 1 is less...

no. 2 example

[0134] For the second embodiment, the arrangement of multiple calibration devices 7 differs from that of the first embodiment in that six calibration devices 7 are arranged on a reference plane outside the preset reference frame K, and the specific method is as follows:

[0135] 1. If Figure 6A , to obtain the overall top view model of the articulated construction machinery;

[0136] 2. If Figure 6B , the overall top view model retains only a partial model of the area where the first hinged structure section 1 outline is located, and the first hinged structure section 1 outline refers to the actual outer edge of the first hinged structure section 1;

[0137] 3. If Figure 6C , find the actual area corresponding to the part of the model in the actual vehicle body, and offset the preset distance L outward relative to the actual area, mark the preset reference frame K on the reference plane, and the preset reference frame K is a rectangle;

[0138] 4. If Figure 6D , when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com