Vacuum pressure swing adsorption oxygen production equipment

A technology of vacuum pressure swing adsorption and oxygen equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

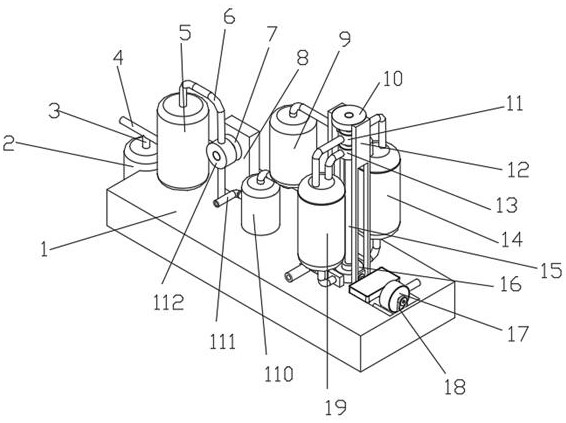

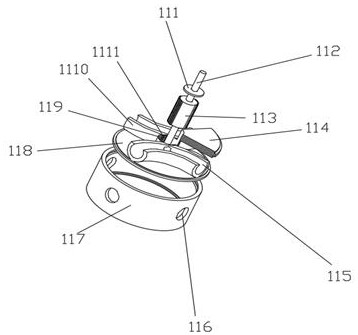

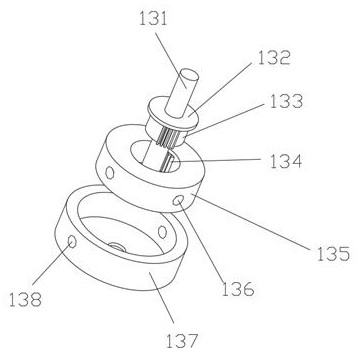

[0033] see Figure 1-7 As shown, the vacuum pressure swing adsorption oxygen equipment includes a base 1, a liquid oxygen tank 2, a liquid oxygen tank connecting pipe 3, an oxygen output pipe 4, an oxygen storage tank 5, a connecting pipe 6, an oxygen compressor driving motor 7, and a motor fixing frame 8. Oxygen balance tank 9, stepping motor 10, adsorption system output adjustment device 11, stepping motor fixing frame 12, adsorption system pressure equalization adjustment device 13, first adsorption system tank 14, connecting rotating shaft 15, intake and exhaust Circulation control device 16, Roots blower unit 17, Roots blower driving device 18, second adsorption system tank 19, oxygen buffer tank 110, unqualified venting pipeline 111 and oxygen compressor 112, Roots blower driving device 18 is embedded in On the inner side of the head end of the base 1, the Roots blower unit 17 is fixed on the upper end of the base 1, the Roots blower driving device 18 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com