Carboxyl-functionalized rubber cross-linked elastomer capable of being repeatedly processed and preparation method thereof

A carboxyl-functionalized and cross-linked elastomer technology, applied in the field of rubber vulcanization, can solve the problems of blooming, storage prone to explosion, carcinogen nitrosamines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

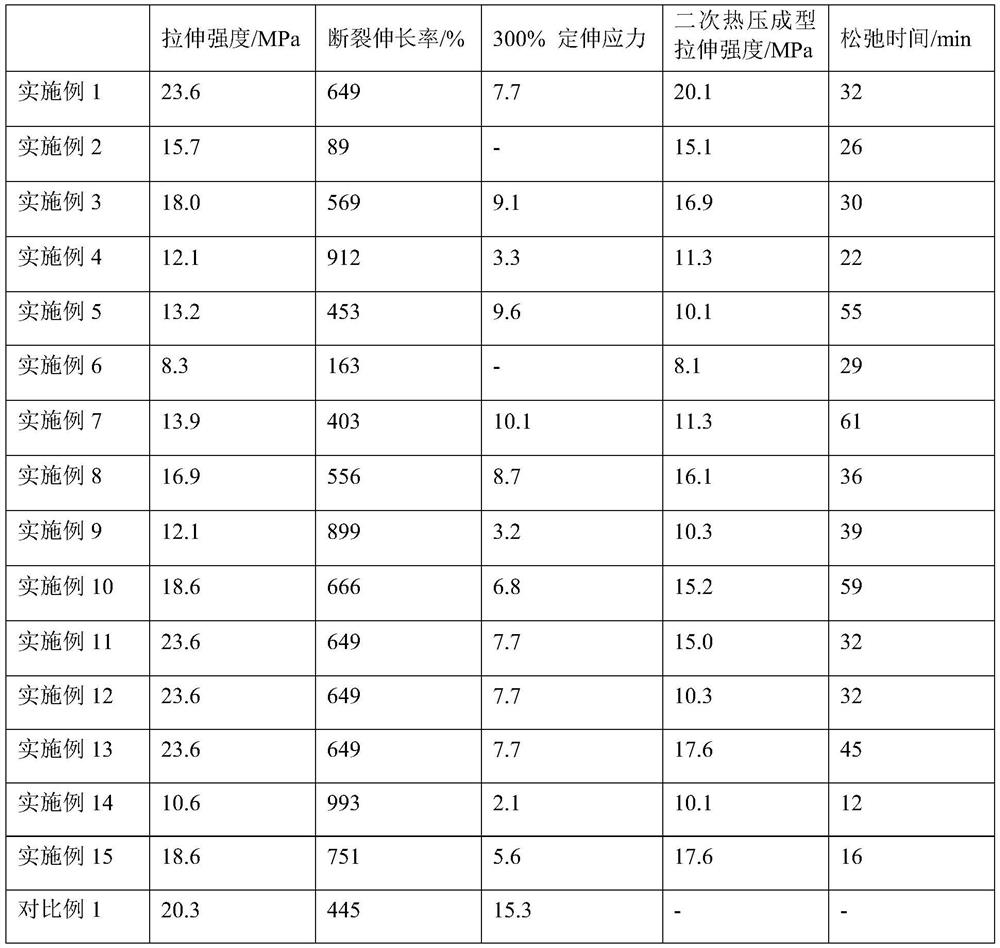

Examples

Embodiment 1

[0046] (1) Rubber mixing: take by weighing 100g acrylonitrile-butadiene-methacrylic acid copolymer glue (the copolymerization ratio of acrylonitrile unit is 26.5%, and the copolymerization ratio of methacrylic acid unit is 7%), adjust the mill roll distance to 0.5mm, keep the temperature of the roller at 50°C, and the front and rear speed ratio of the roller is 1:1.4. The rubber is masticated three times on the Φ160×320 double-roll mill, and then the roller distance of the mill is adjusted to 0.8mm to make the rubber roll , followed by adding 0.8phr transesterification catalyst zinc acetate Zn(OAc) 2 , 2phr anti-aging agent 4020, 40phr carbon black N300, 8phr epoxy soybean oil, cut twice, alternately make six triangle bags and six rolls, so that the epoxy soybean oil can be evenly dispersed, and then the film is produced.

[0047] (2) Vulcanization: vulcanize on a flat vulcanizer, and press it into a vulcanized rubber sample with a thickness of 2mm under the condition of 15MPa...

Embodiment 2

[0050] Different from Example 1, the content of carboxyl groups and the amount of crosslinking agent in the acrylonitrile-butadiene-methacrylic acid copolymer glue, in this embodiment, the carboxyl content is 30% (the copolymerization ratio of acrylonitrile units is 26.5% , the copolymerization ratio of methacrylic acid units is 30%), and the crosslinking agent consumption is 40phr. Other techniques and consumption are identical with embodiment 1.

Embodiment 3

[0052] The difference from Example 1 is the type of rubber and the type of crosslinking agent. In this embodiment, the rubber is styrene-butadiene-methacrylic acid copolymer (the copolymerization ratio of styrene units is 23.5%, methyl The copolymerization ratio of the acrylic acid unit is 3%), and the crosslinking agent is bisphenol A glycidyl ether. Other techniques and consumption are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com