A soil conditioner for regulating acidity and controlling diseases and its application

A soil conditioner and acid-adjusting technology, which is applied in the field of soil acidification improvement and bacterial wilt prevention and control, can solve the problems of unsatisfactory effect, high cost, and large dosage, and achieve the improvement of soil biological function activity, low cost, and long-term drug effect long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

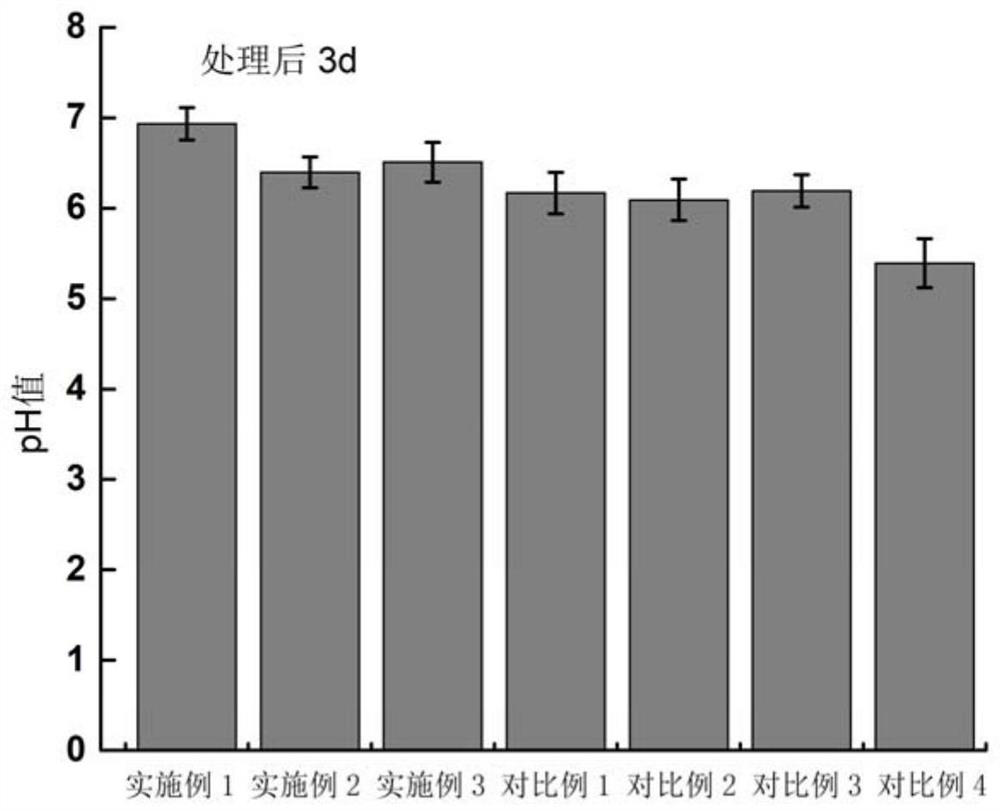

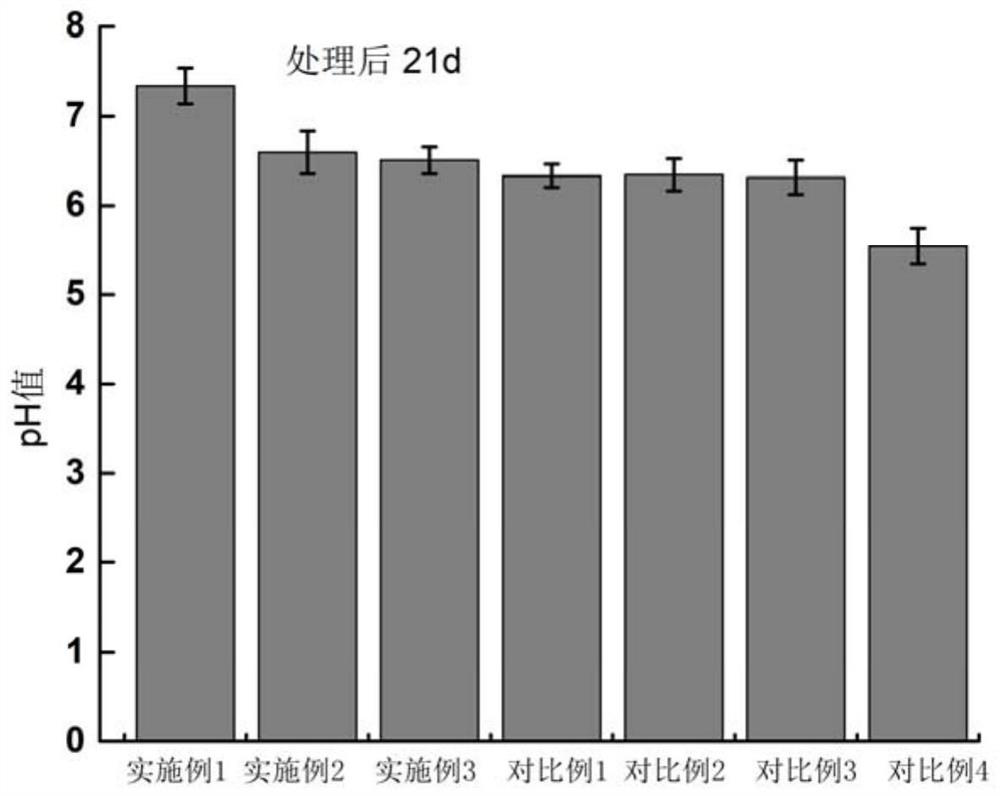

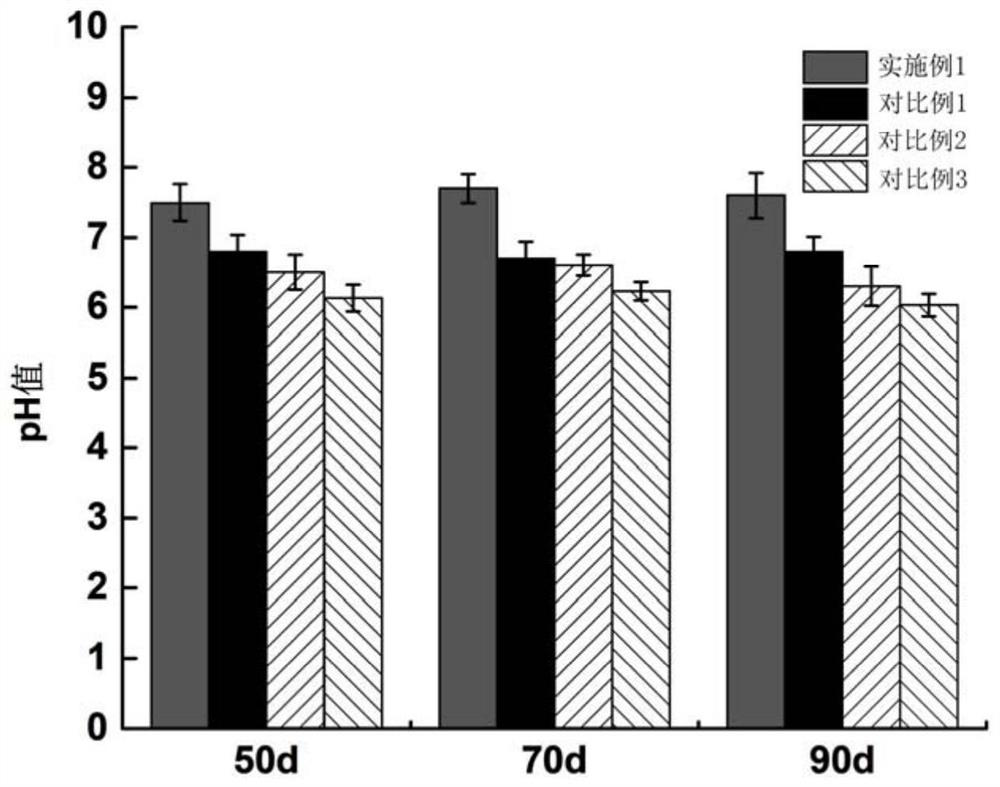

Examples

Embodiment 1

[0044] Embodiment 1: soil conditioner one

[0045] A soil conditioner for acid regulation and disease control, comprising the following raw materials: 8kg plant ash, 2kg oyster powder, 0.1kg sodium metasilicate, and the mass ratio is 4:1:0.05.

[0046] Among them, the plant ash is the residue of one or both of herbaceous and woody plants after burning, and the plant ash is fresh and non-caking powder;

[0047] Plant ash is pretreated before use, and the treatment method is as follows:

[0048] Put the plant ash sample into the heating device, rapidly raise the temperature to 120°C, keep the temperature for 30 minutes, then raise the temperature to 300°C at a heating rate of 50°C / h, and then quickly raise the temperature to 590°C, when the temperature rises to 590°C, keep the temperature for 1 hour, then turn off the power , cooled to room temperature.

[0049] Oyster powder is a powder product obtained by calcining and grinding marine oyster shells at 200°C. The particle siz...

Embodiment 2

[0052] Embodiment 2: soil conditioner two

[0053] A soil conditioner for acid regulation and disease control, comprising the following raw materials: 4kg plant ash, 4kg oyster powder, 0.02kg sodium metasilicate, and the mass ratio is 1:1:0.02.

[0054] Among them, the plant ash is the residue of one or both of herbaceous and woody plants after burning, and the plant ash is fresh and non-caking powder;

[0055] Plant ash is pretreated before use, and the treatment method is as follows:

[0056] Put the plant ash sample into the heating device, rapidly raise the temperature to 150°C, keep the temperature for 30 minutes, then raise the temperature to 300°C at a heating rate of 50°C / h, then rapidly raise the temperature to 590°C, when the temperature rises to 590°C, keep the temperature for 1 hour, then turn off the power , cooled to room temperature.

[0057] Oyster powder is the powder product of marine oyster shells calcined and ground at 200°C. The particle size of oyster p...

Embodiment 3

[0060] Embodiment 3: soil conditioner three

[0061] A soil conditioner for acid regulation and disease control, comprising the following raw materials: 7kg plant ash, 1kg oyster powder, 0.08kg sodium metasilicate, and the mass ratio is 7:1:0.08.

[0062] Among them, the plant ash is the residue of one or both of herbaceous and woody plants after burning, and the plant ash is fresh and non-caking powder;

[0063] Plant ash is pretreated before use, and the treatment method is as follows:

[0064] Put the plant ash sample into the heating device, rapidly raise the temperature to 100°C, keep the temperature for 30 minutes, then raise the temperature to 300°C at a heating rate of 50°C / h, and then quickly raise the temperature to 590°C, when the temperature rises to 590°C, keep the temperature for 1 hour, then turn off the power , cooled to room temperature.

[0065] Oyster powder is the powder product of marine oyster shells calcined and ground at 200°C. The particle size of oy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com