High-pressure fluid pulsation control test platform

A test platform, high-pressure fluid technology, applied in the direction of fluid dynamics test, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve problems such as fatigue damage of hydraulic system, and achieve compact structure and pressure pulsation attenuation effect. Excellent and good pulsation attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

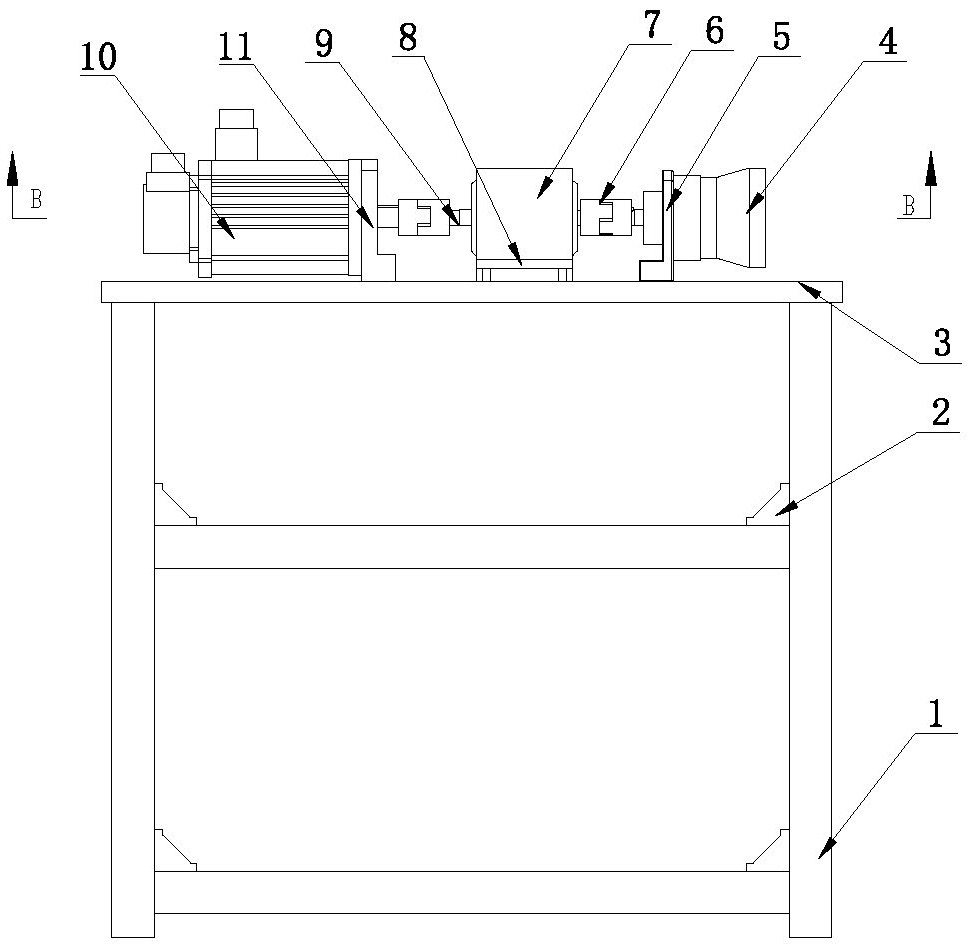

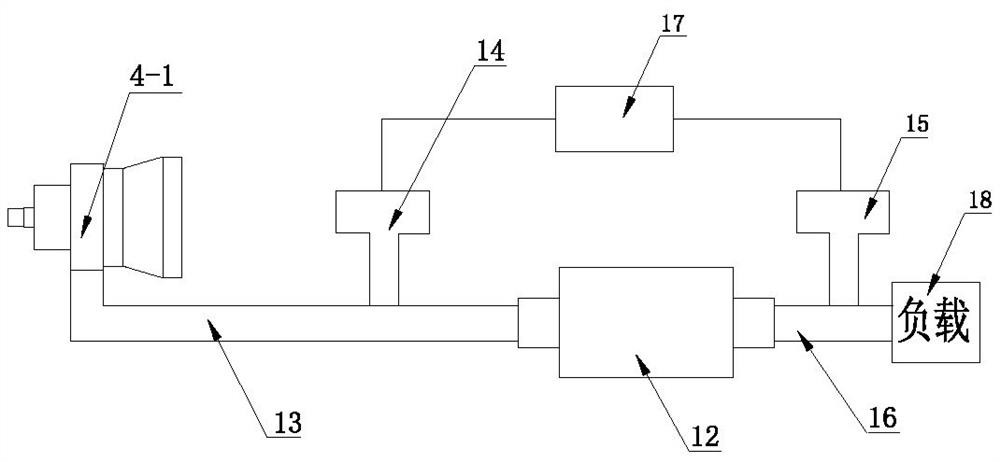

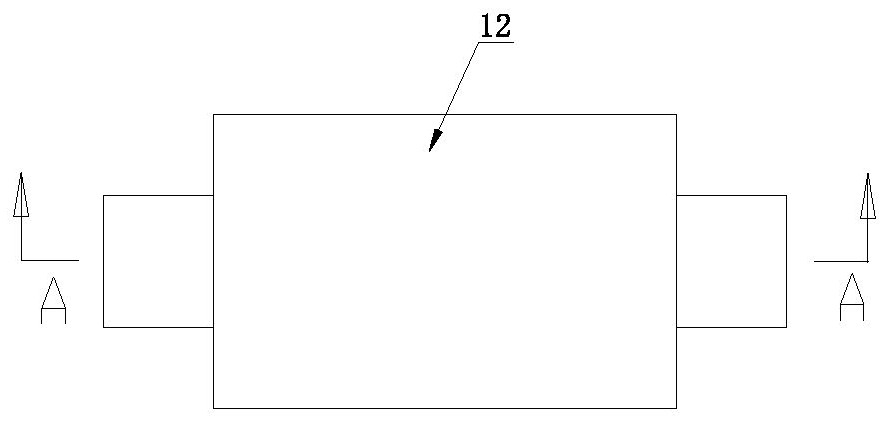

[0023] Such as Figure 1-2 A high-pressure fluid pulsation control test platform shown includes a test bench, a servo motor 10, a torque sensor 7 and an axial piston pump 4. The test bench includes a table top 3 and a test bench support 1, and also includes a fluid pulsation control device 12, The test bench bracket 1 is fixed to the table top 3 by screws. There are multiple fixing holes on the table top 3. The bracket connector 2 is provided on the test bracket. The bracket connector 2 is provided with a keyway. The bracket connector 2 and the test bench bracket 1 adopt The bolts are fixed; the servo motor 10, the torque sensor 7 and the axial piston pump 4 are arranged and fixed on the test bench in sequence, the servo motor 10 is fixed on the test bench through the servo motor connecting plate 11 and screws, the servo motor 10 and the servo motor connecting plate The screw holes on the four corners of 11 are fixedly connected by screws, and the bottom of the servo motor con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com