Sampling method for building steel bar detection

A technology for buildings and steel bars, applied to building structures, buildings, building components, etc., can solve problems such as missing steel bars, unfavorable repairs, insufficient effective steel bars, etc., and achieve the effects of easy repair, reduced damage, and improved integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

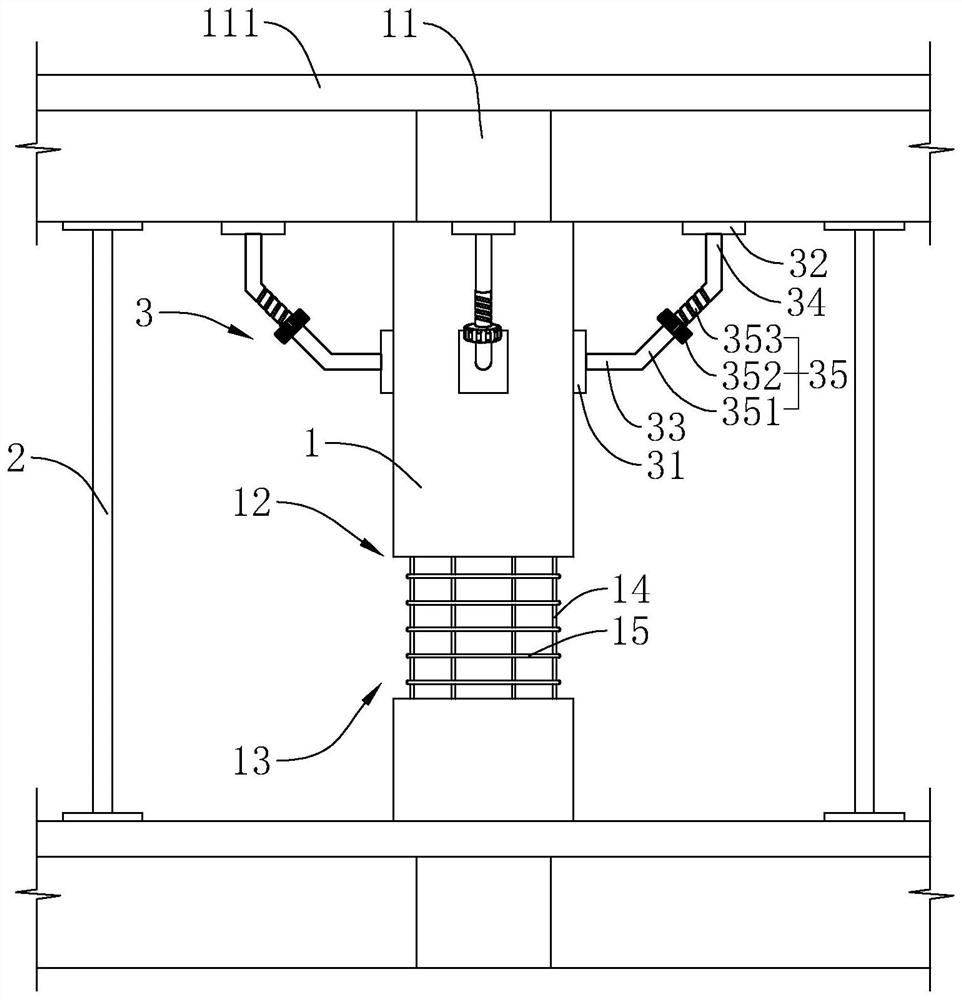

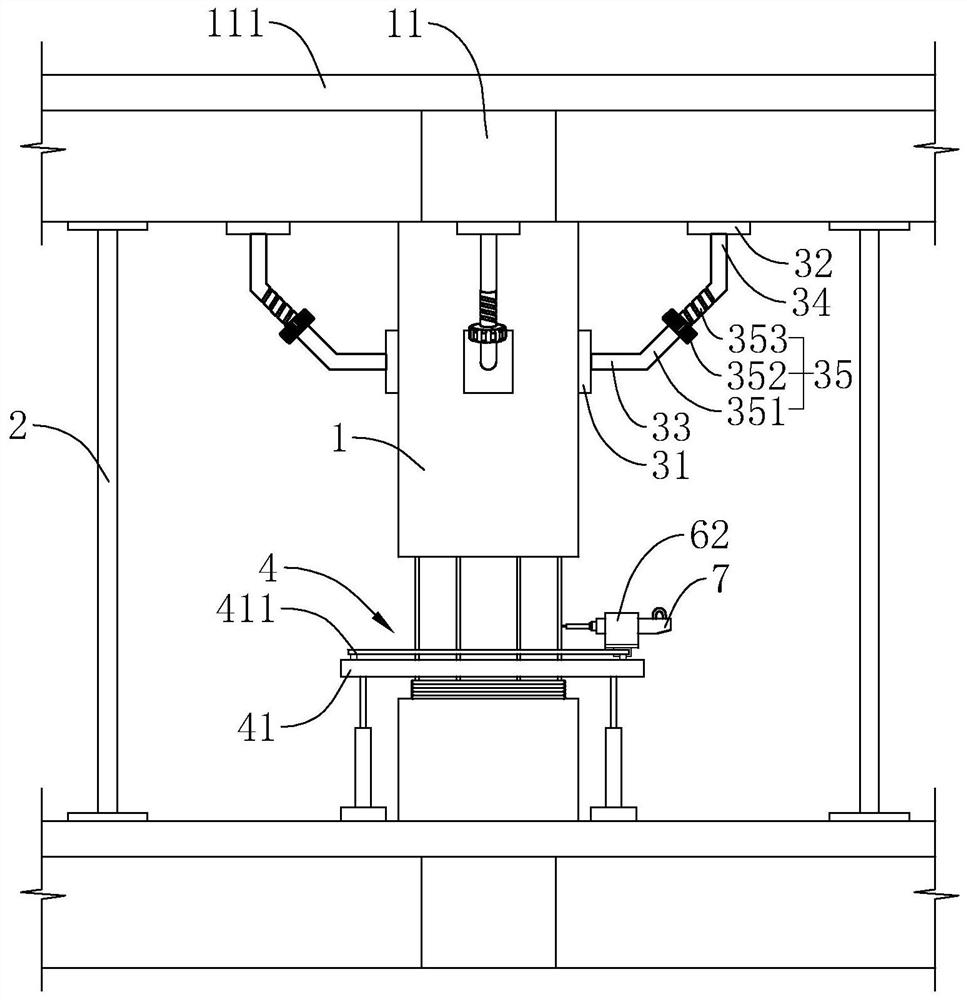

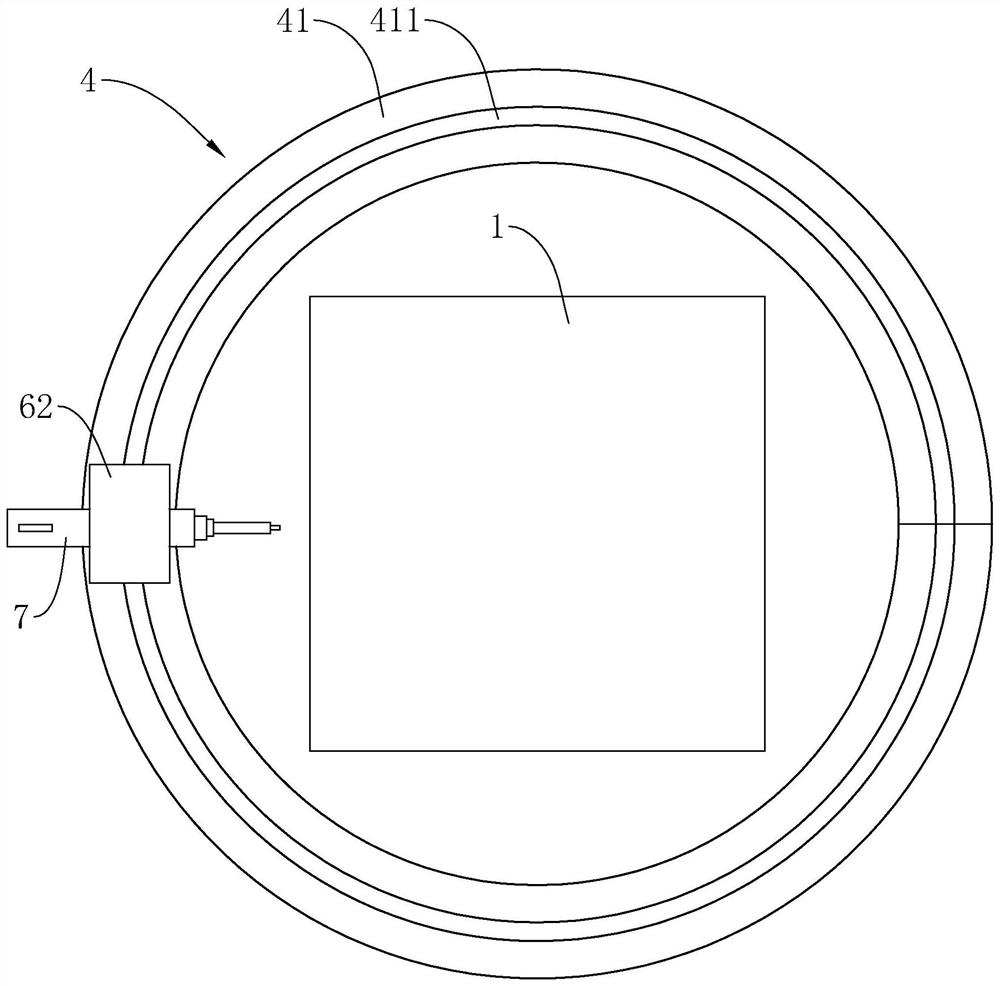

[0044] refer to figure 1 , is a kind of sampling method that is used for the steel bar detection of building disclosed by the present invention, comprises the following steps;

[0045] S1, unloading support;

[0046] The load on the floor 111 corresponding to the column 1 is removed, and the vertical support bar 2 is supported at the bottom of the main beam 11 directly connected to the column 1 . The vertical distance between each support rod 2 and the surface of the adjacent column 1 is not less than 1m. Wipe the top surface of the column 1 and the bottom wall of the main beam 11 close to the column 1 , and support the diagonal brace 3 between the outer wall of the column 1 and the bottom wall of the main beam 11 .

[0047] The diagonal brace 3 includes a first abutting plate 31 , a second abutting plate 32 , a first connecting rod 33 and a second connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com