Traction wheel and threading machine comprising traction wheel

A technology of traction wheel and threading machine, applied in the field of threading machine, can solve the problems that have not been paid attention to and solved, and achieve the effect of reducing traction, reducing cost and improving threading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

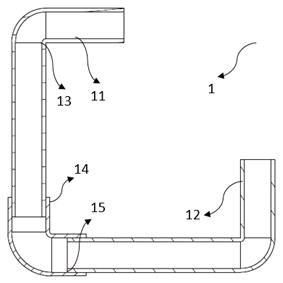

[0039] figure 1 It is a schematic cross-sectional view of the embedded pipe with multiple 90° straight bends and connecting pipes. There are many wiring pipes 11 and 12 in the embedded pipe 1 of the building wall, and the multiple wiring pipes 11 and 12 themselves have a plurality of 90° straight angles 13, and the wiring pipes 11 and 12 are formed at the 90° straight angle. A connecting pipe 14 is connected, and the inner diameter of the connecting pipe 14 is greater than or equal to the outer diameter of the connected pipe. Here, a variable section 15 is formed. When the lead wire is bent through a 90° straight angle, it is particularly easy to get stuck in the variable section. Department 15.

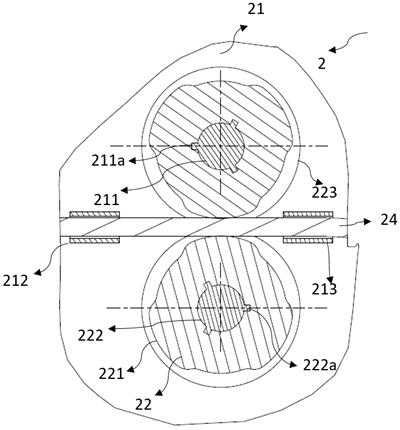

[0040] Such as figure 2 As shown, firstly, this embodiment provides a traction wheel 22 , at least one protruding feature 221 is provided on the outer edge of the traction wheel 22 , and the threading wire 24 is driven by the protruding feature 221 to make intermittent movements. ...

Embodiment 2

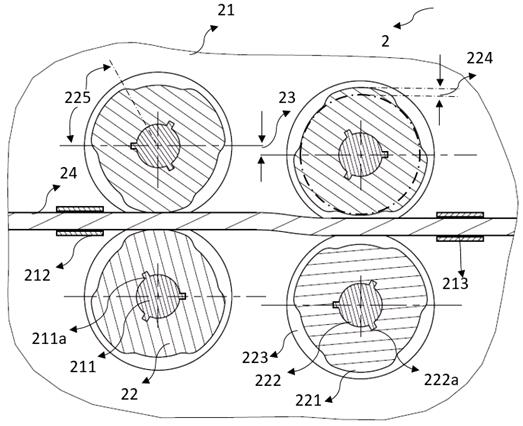

[0048] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: image 3 As shown, in this embodiment, two sets of front and rear transmission assemblies (only the output shaft 211 is shown) are arranged in the frame 21, and there are three evenly distributed raised features 221 on the traction wheel 22, each raised feature 221 Width or amplitude 225 is less than or approximately equal to 60°, ie, raised feature 221 is less than or approximately equal to 60°. For example, 58° means that each driving stroke of the traction wheel 22 is less than or approximately equal to the no-load stroke. The output torque of the motor varies with the load, and an impact can be formed when the traction wheel 22 is converted from the no-load stroke to the drive stroke.

[0049] In order to ensure enough disturbance and impact to help the threading wire 24 smoothly pass t...

Embodiment 3

[0052] The same features of this embodiment and the second embodiment will not be repeated, and the different features of this embodiment and the second embodiment are: still the same figure 2 As shown in , in this embodiment, the centers of the two pairs of traction wheels 22 at the front and rear can have an offset distance 23, thereby intensifying the disturbance of the threading wire 24, so that the threading wire 24 can pass through the 90° straight bend angle 13 and the variable section 15 more smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com