Automatic bearing polisher

A technology of grinding machine and grinding mechanism, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment designed for grinding the rotating surface of workpieces, etc. It can solve the problems of affecting repeated use and poor filtering effect of cooling fluid, and improve the filtering effect , Reduce the impact of machining accuracy and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

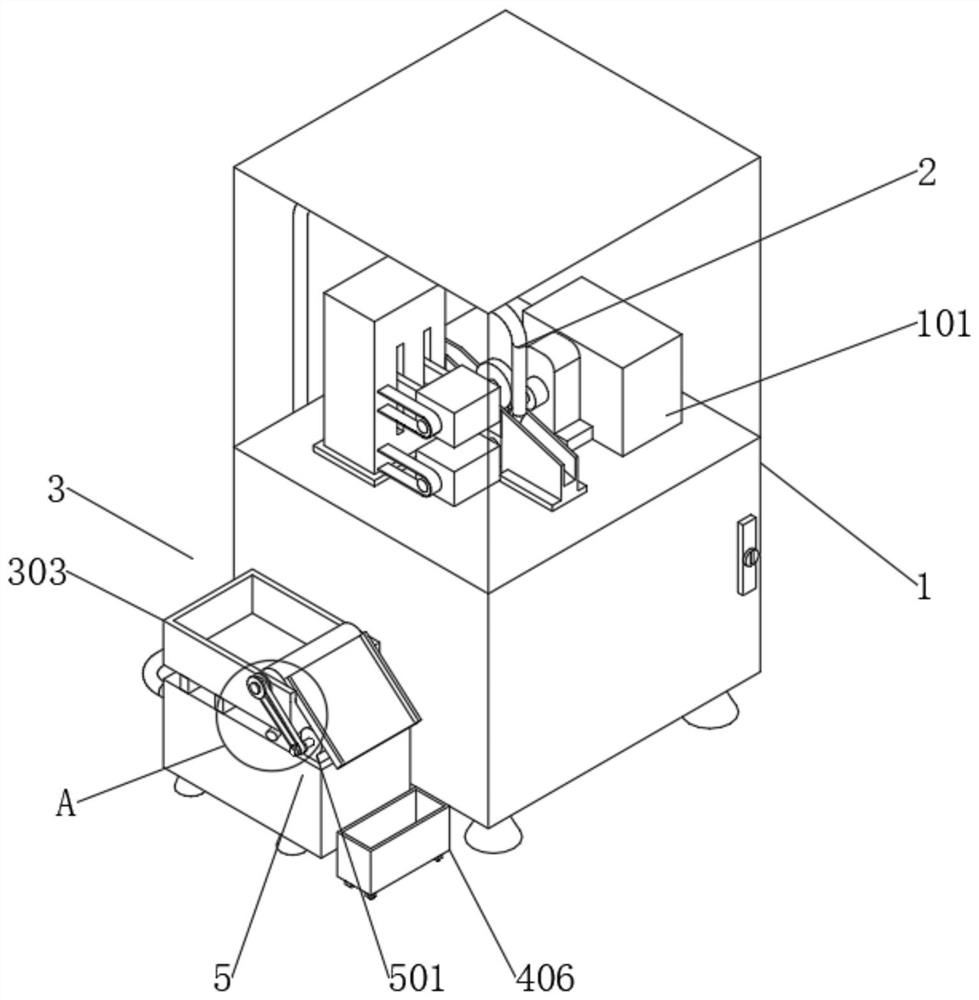

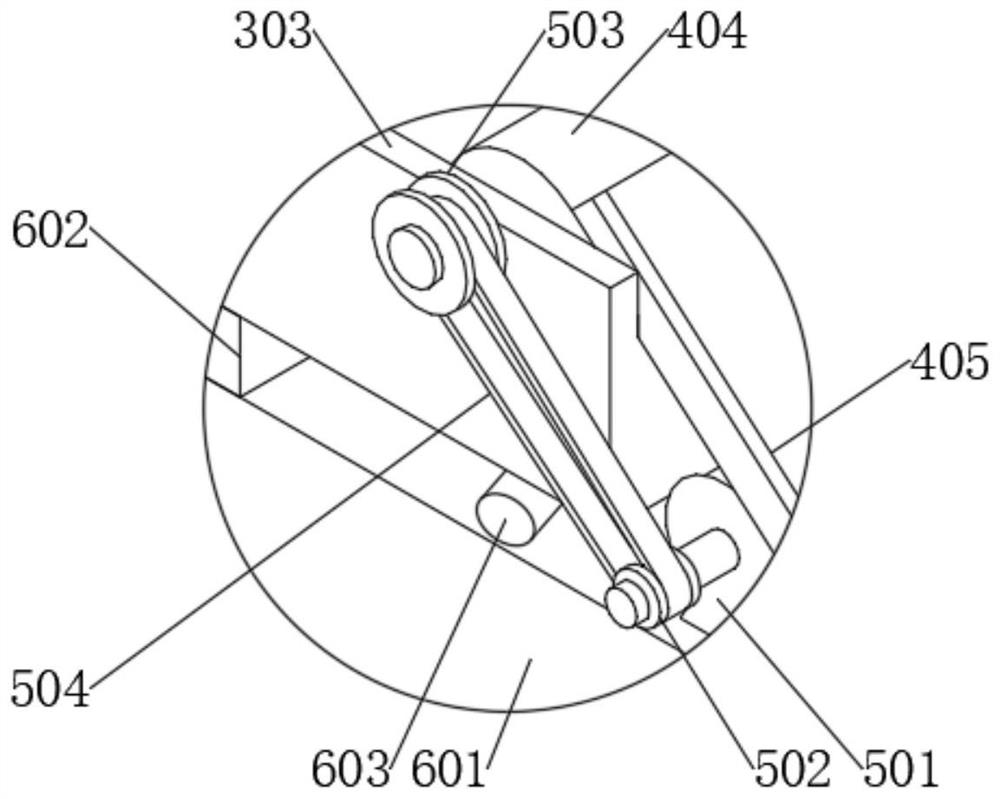

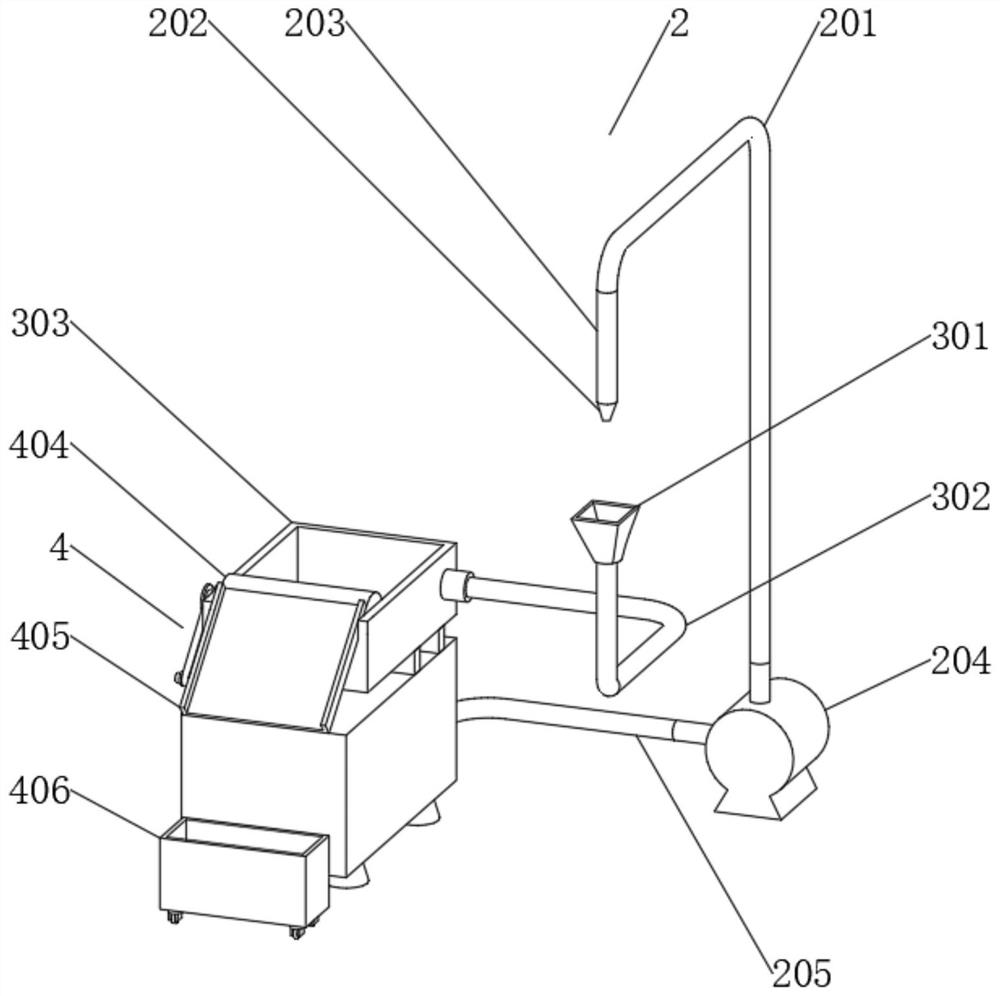

[0027] The invention discloses an automatic bearing grinding machine. Figure 1-Figure 7 As shown, the grinder body 1 is included, the grinder body 1 is connected with a grinding mechanism 101, the grinding mechanism 101 is provided with a coolant circulation mechanism 2, and the coolant circulation mechanism 2 includes a connecting pipe 201, which is convenient for transporting coolant, and the connecting pipe 201 A spray head 202 is arranged on the side close to the grinding mechanism 101, which is convenient for spraying cooling liquid. A cooling pipe 203 is connected between the connecting pipe 201 and the spray head 202, which is convenient for adjusting the angle of the spray head 202 according to the actual situation. The connecting pipe 201 is located outside the grinding machine body 1 One end of the pump is connected with a circulating water pump 204, the model of the circulating water pump 204 is 25WZD-1.1, the rotating speed is 2850r / min, and the power is 1.1KW. li...

Embodiment 2

[0030] The invention discloses an automatic bearing grinding machine, comprising a grinding machine body 1, a grinding mechanism 101 is connected to the grinding machine body 1, a cooling liquid circulation mechanism 2 is arranged on the grinding mechanism 101, and the cooling liquid circulation mechanism 2 includes a connecting pipe 201, To facilitate the delivery of coolant, the side of the connecting pipe 201 close to the grinding mechanism 101 is provided with a spray head 202, which is convenient for spraying coolant. One end of the pipe 201 located outside the grinding machine body 1 is connected with a circulating water pump 204. The model of the circulating water pump 204 is 25WZD-1.1, the speed is 2850r / min, and the power is 1.1KW. A delivery pipe 205 is connected between the circulating water pump 204 and the filter mechanism 6. It is convenient to extract the coolant in the collection box 601.

[0031] ginseng Figure 3-Figure 4 As shown, one side of the grinding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com