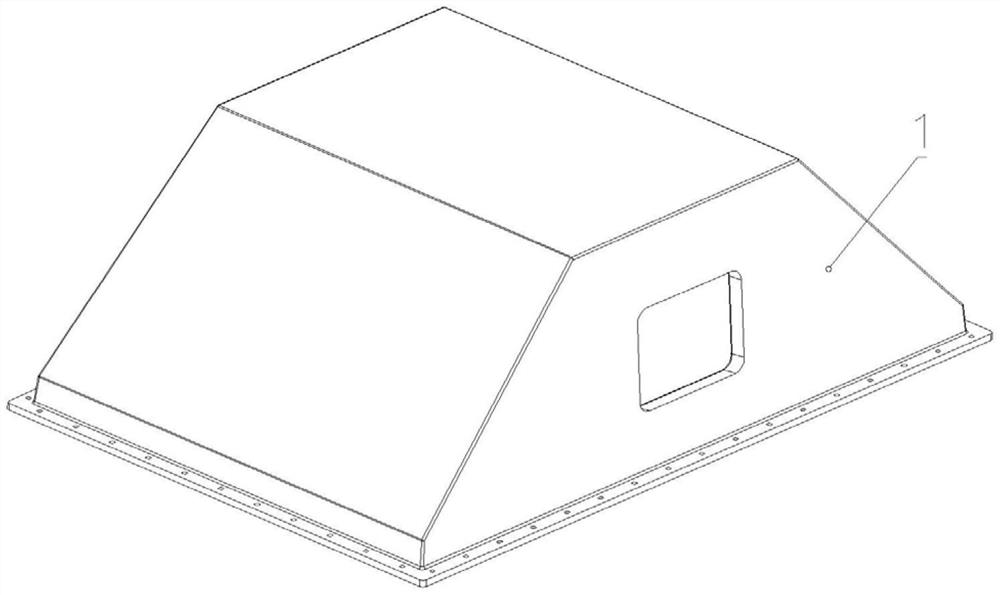

Refractory wheel cover of rail transit vehicle and manufacturing method thereof

A technology for rail transit vehicles and wheel covers, which is applied to chemical instruments and methods, railway car bodies, railway car body parts, etc., and can solve problems such as wheel cover damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

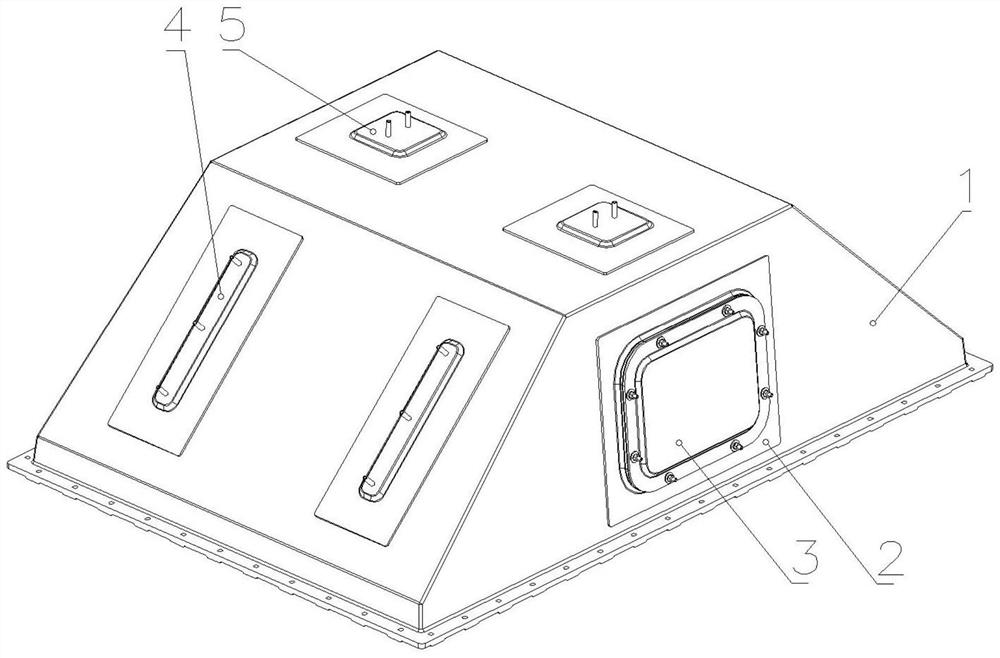

[0043] Embodiment 1, the manufacture method of the fireproof wheel cover of rail transit vehicle, comprises the following steps:

[0044] ① Make a mold according to the size of the surface of the inner cavity of the wheel cover main body 1;

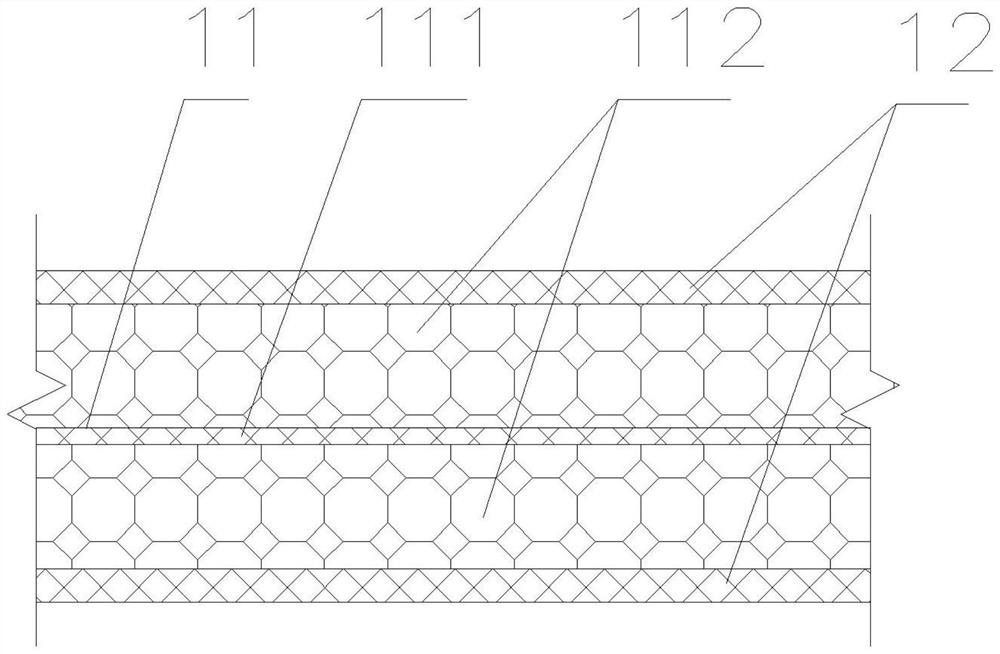

[0045] ②The two sandwich cores 112 are connected with the separator 111 to form a composite sandwich panel 11;

[0046] ③ spread the inner layer of glass fiber cloth, place the composite sandwich panel 11, and lay the outer layer of glass fiber cloth;

[0047] ④ Configure phenolic resin and curing agent in proportion, and inject the mixed resin and curing agent into the mold;

[0048] ⑤ Put the mold into the curing furnace or autoclave, pressurize and heat to cure the resin;

[0049] ⑥Take out the wheel cover main body 1 after cooling down.

Embodiment 2

[0050] Embodiment 2, the manufacture method of the fireproof wheel cover of rail transit vehicle, comprises the following steps:

[0051] (1) Production of wheel cover main body 1:

[0052] S1. Make a lower mold according to the surface of the inner cavity of the wheel house main body 1, and make a movable insert according to the size of the inspection port of the wheel house main body 1.

[0053] S2. Making the composite sandwich panel 11: use two sandwich cores 112 and partitions 111 to glue together to form a "core material-partition-core material" type, and then carve out the shape, chamfers, openings, etc. according to the typesetting blanking diagram feature.

[0054] S3. Laying: clean the surface of the mold, place and position the movable inserts; lay the inner layer of glass fiber cloth, place the composite sandwich panel 11, and lay the outer layer of glass fiber cloth;

[0055] S4. Resin infusion: configure phenolic resin and curing agent in proportion, and inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap