A high-strength cement-based repair material for concrete prefabricated components

A technology for high-strength cement and prefabricated components, applied in the field of high-strength cement-based repair materials, can solve problems such as poor strength, shrinkage cracking, and inability to achieve, and achieves reduced mixing water consumption, strong anti-carbonation ability, and increased compaction. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

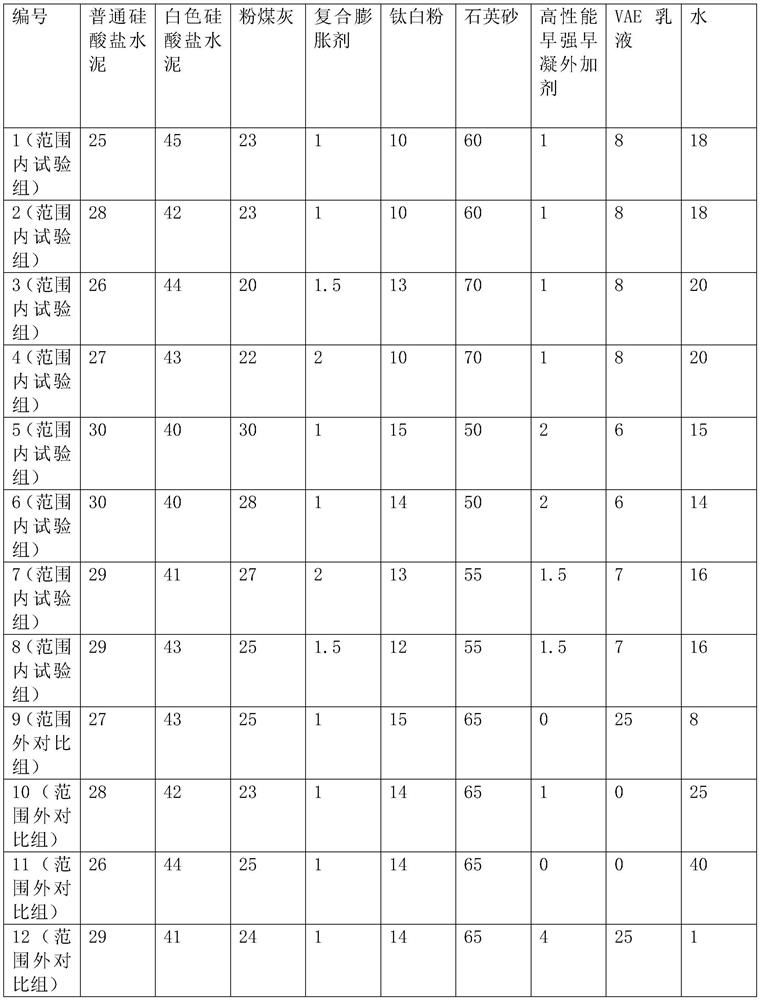

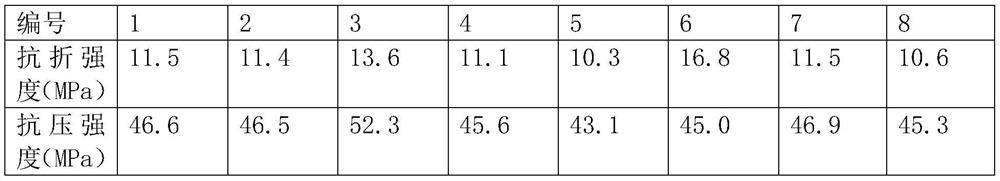

[0019] The invention provides a high-strength cement-based repair material for concrete prefabricated components, which comprises the following components in parts by weight: 20-40 parts of ordinary Portland cement, 40-60 parts of white Portland cement, and 20-60 parts of fly ash 40 parts, 1-2 parts of concrete expansion agent, 10-20 parts of titanium dioxide, 50-100 parts of quartz sand, 1-3 parts of high-performance early strength and early setting admixture, 5-10 parts of VAE emulsion, 10-20 parts of water .

[0020] Preferably, the following components are included in parts by weight: 20-40 parts of ordinary Portland cement, 50-60 parts of white Portland cement, 30-40 parts of fly ash, 1-2 parts of concrete expansion agent, 10 parts of titanium dioxide -20 parts, 50-80 parts of quartz sand, 1-3 parts of high-performance early strength and early setting admixture, 8-10 parts of VAE emulsion, 10-20 parts of water.

[0021] Preferably, it includes the following components by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com