Reclaimed material drying roller and reclaimed material drying method

A technology of recycled materials and drums, which is applied in the field of recycled materials drying drums and recycled materials drying, and can solve problems such as sticking and leakage of fine material feeding rings, uncertain stable operation, and bonding of drying drums, etc. , to achieve the effect of saving labor costs, reducing material leakage and sticking problems, and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

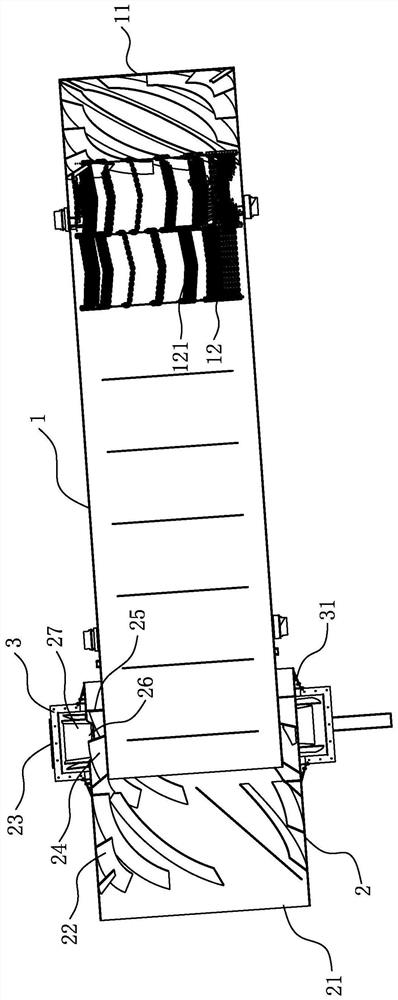

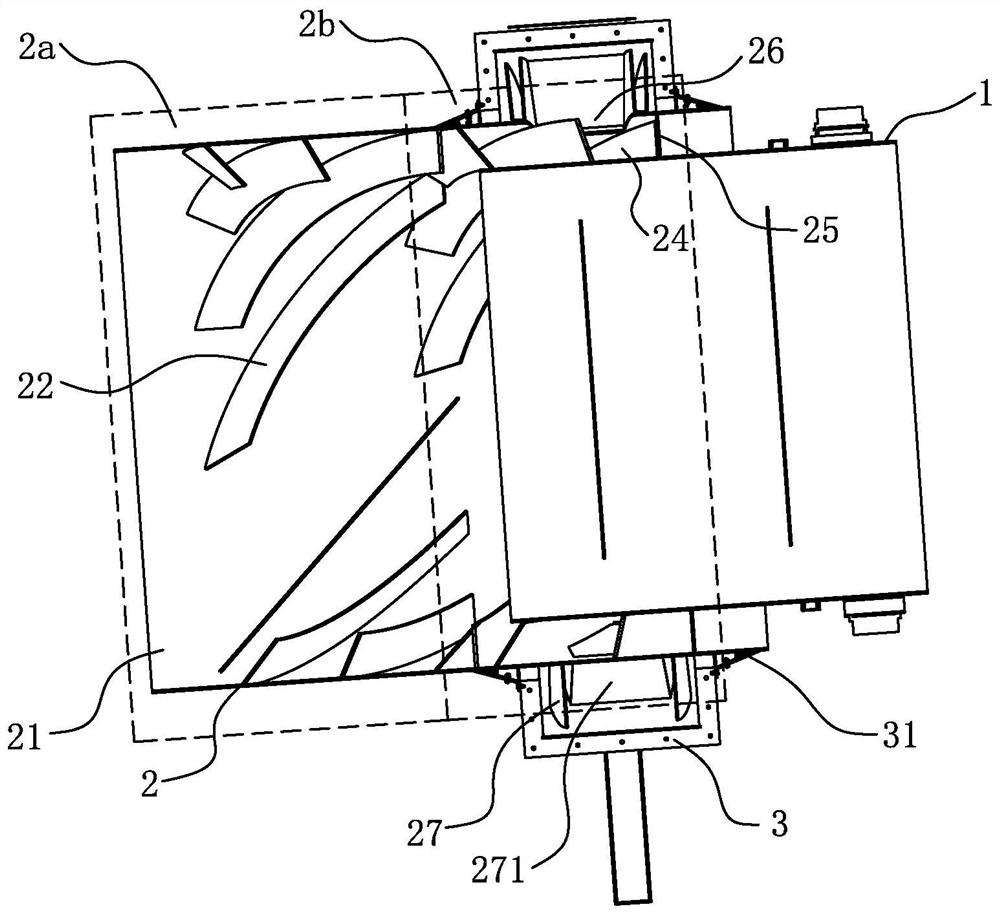

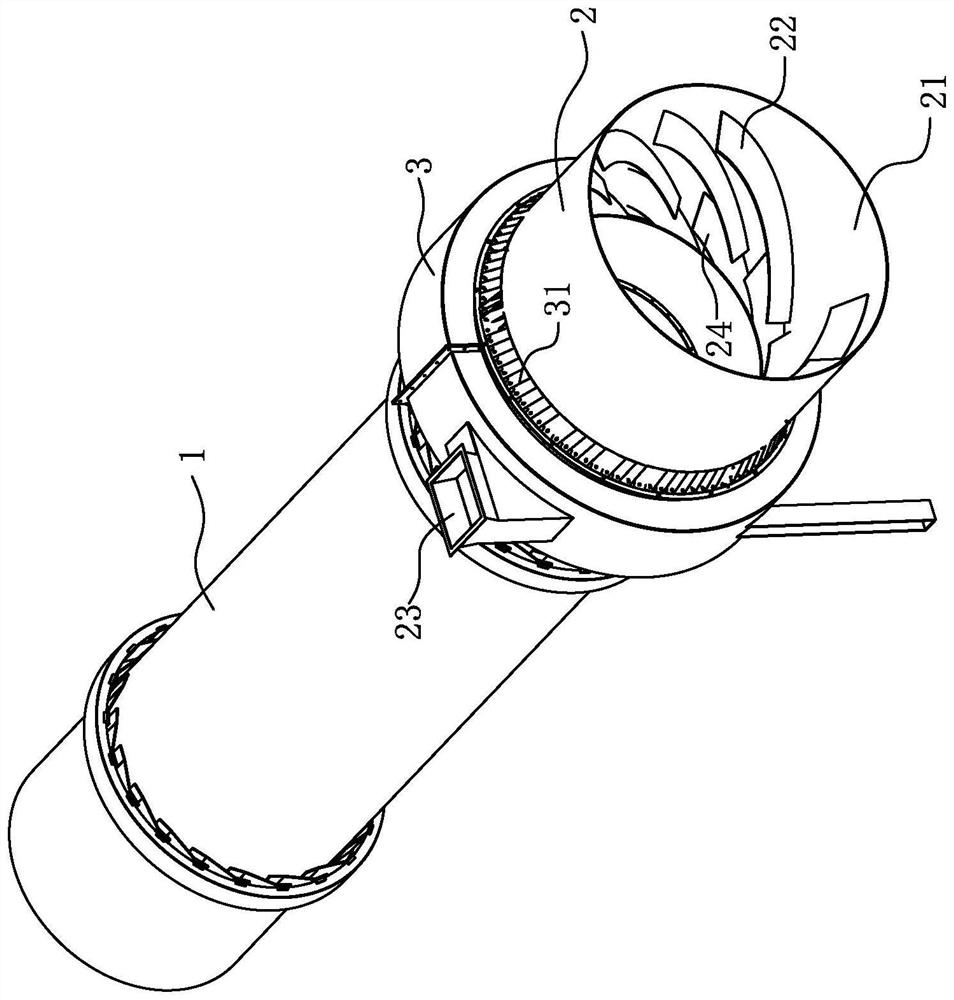

[0025] refer to Figure 1 to Figure 5 As shown, a recycled material drying drum includes a first cylinder 1 , a second cylinder 2 , and an annular feed box 3 .

[0026] The first cylinder 1 and the second cylinder 2 are connected. The first cylinder 1 and the second cylinder 2 are arranged obliquely and rotate around the axis. The hot air enters from one end of the second cylinder 2 and passes through the second cylinder 2 in turn. 1. The first cylinder 1; the second cylinder 2 is divided into a material guiding area 2a and a mixing area 2b. The end of the mixing area 2b is provided with a discharge port 21, and the mixing area 2b is provided with wrapping materials facing the discharge The mixing blade 22 conveyed in the direction of the mouth 21, the fine aggregate feed port 23 is provided on the material guide area 2a, and the material guide blade 24 for guiding the fine aggregate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com