Roof bolter angle adjusting and supporting device and using method thereof

A technology of angle adjustment and support device, which is applied in the directions of support device, bolt installation, earthwork drilling, etc. Accurate and difficult to construct anchor holes, bottom anchor holes and other problems, to achieve the effect of reducing labor intensity, good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

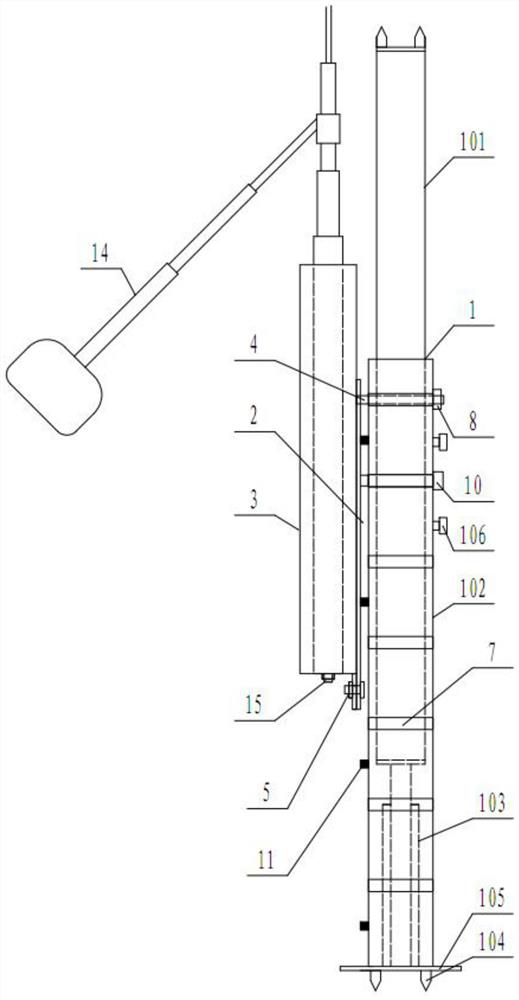

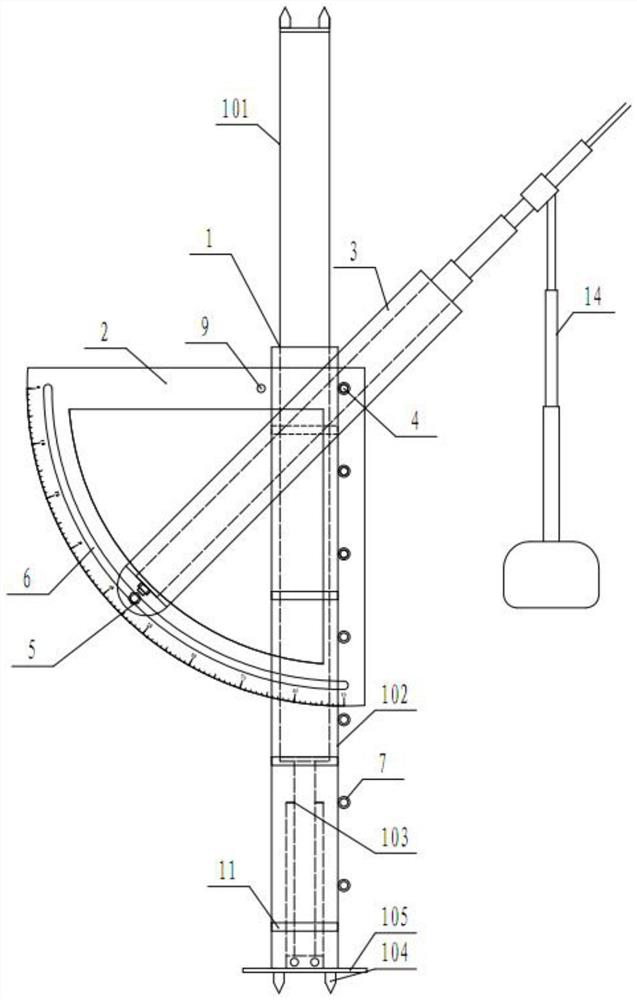

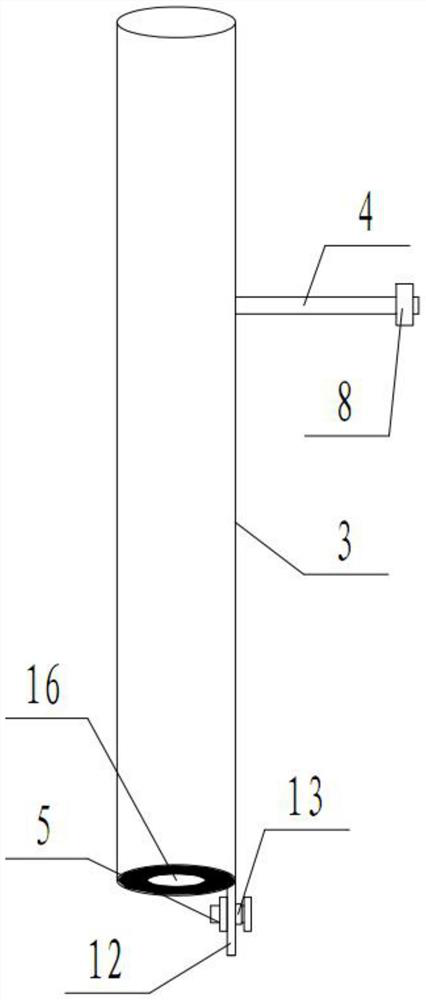

[0029] Embodiment 1: as Figure 1-4 As shown, a bolter angle adjustment support device includes a telescopic column 1, an angle plate 2 and a bolter sleeve 3, the angle plate 2 is a 90° fan-shaped frame structure, and is fixedly connected to the telescopic column 1, and the angle plate 2 Scale 17 is set on the arc-shaped side of the bolter sleeve 3. The tail end of the bolter sleeve 3 is sealed. The middle and upper part is fixedly connected with the rotating shaft 4. The end is fixedly connected to the angle-adjusting guide arc-shaped through hole 6 provided on the arc-shaped side of the angle plate 2 through bolts 5. The radial center of the angle-adjusting guide arc-shaped through hole 6 coincides with the axis of the rotating shaft 4. The bolter sleeve 3 is used To fix the bolter 14, the tail end of the bolter 14 is welded with a screw rod 15, and the screw rod 15 passes through the reserved hole 16 at the tail end of the bolter casing 3 and is locked with a nut.

[0030]...

Embodiment 2

[0038]Embodiment 2: A method of using a bolter angle adjustment support device, the method is: when constructing a bolt (cable) hole, connect the hydraulic cylinder to the hydraulic system, open the inlet valve, and the hydraulic cylinder pushes the inner column until The telescopic column is tightly fixed to the top and bottom of the construction roadway section to ensure that the conical body at the top and bottom of the telescopic column is embedded in the roof and floor of the roadway. According to the needs of construction drilling construction angle, adjust the installation position of the angle adjustment plate, the sector of the angle plate is facing upwards or towards, and insert the other through hole into the positioning pin to fix the angle plate, and insert the rotating shaft into the setting of the telescopic column Use nuts in the casing at the position to fix the bolter sleeve on the telescopic column. According to the designed construction angle, adjust the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com