Linear Fresnel condenser

A linear Fresnel and concentrator technology, applied in the field of solar energy utilization, can solve the problems of affecting the optical efficiency of linear Fresnel solar system, reducing the concentration ratio of secondary reflectors, and high manufacturing costs of vacuum tubes, so as to reduce construction costs. And operation and maintenance costs, reduce heat radiation loss, reduce the effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

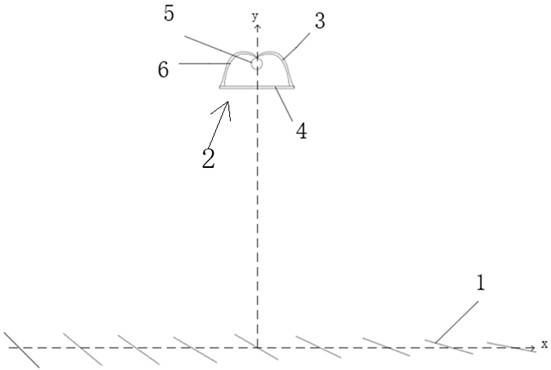

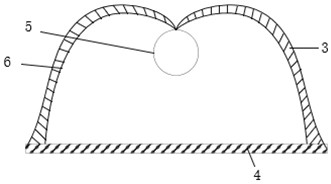

[0014] Such as figure 1 As shown, the concentrator is composed of a primary reflector 1, a secondary concentrator 2, an insulating layer 3 and a glass cover plate 4 coated with a spectral selective reflection film on the surface; The heat collecting tube 5 and the secondary reflection mirror 6 are composed of a metal heat collecting film with a permanent absorption film.

[0015] The upper layer of the glass cover plate is coated with a spectrally selective reflection film, and its structure is SiO2 from the inside to the outside. 2 layer / AZO layer / Al 2 o 3 Layer / Substrate / SiO 2 The layer is characterized by high transmittance to visible light (T ≥ 90%), mid-infrared reflectivity > 85%, high reflection and low emissivity (ε 100℃ ≤0.10), the width is 440mm. The substrate is made of high borosilicate glass with a thickness of 4mm.

[0016] The shape of the secondary reflector is compound parabolic concentrator (CPC), the arc length of the reflecting surface is 760mm, the m...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, another spectrally selective reflection film is selected.

[0025] The spectrally selective reflective film on the glass cover, its structure is SiO from the inside to the outside 2 layer / CN layer / Al 2 o 3 Layer / Substrate / SiO 2 layer, which is characterized by high transmittance of visible light (T≥90%), high infrared reflection and low emissivity (ε 100℃ ≤0.10), the width is 440mm. The substrate is made of high borosilicate glass with a thickness of 4mm.

[0026] Compared with ordinary concentrators, the optical efficiency is increased by 8%; the radiation heat loss is reduced by 20%, and the overall heat loss is reduced by 65%. System efficiency increased by 9%.

Embodiment 3

[0028] In this embodiment, on the basis of Embodiment 1, another spectrally selective reflection film is selected.

[0029] The glass cover is coated with a spectrally selective reflection film, and its structure is SiO from the inside to the outside. 2 layer / AZO layer / Al 2 o 3 Layer / Substrate / SiO 2 layer, which is characterized by high transmittance of visible light (T≥90%), high infrared reflection and low emissivity (ε 100℃ ≤0.10), the width is 440mm. The substrate is made of high borosilicate glass with a thickness of 4mm.

[0030] Compared with ordinary concentrators, the optical efficiency is increased by 8%; the radiation heat loss is reduced by 21.2%, and the overall heat loss is reduced by 68.5%. The system efficiency has increased by more than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com