Fully automatic subglacial sediment vibrating sampler

A sediment and sampler technology, which is applied in the field of fully automatic subglacial sediment vibrating sampler, can solve the problems of inability to directly apply Antarctic subglacial sediment sampling, vibrator parts, and large radial dimensions of the trigger mechanism, etc., and achieve saving Effects of surface working time, radial dimension reduction, risk reduction of false triggering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

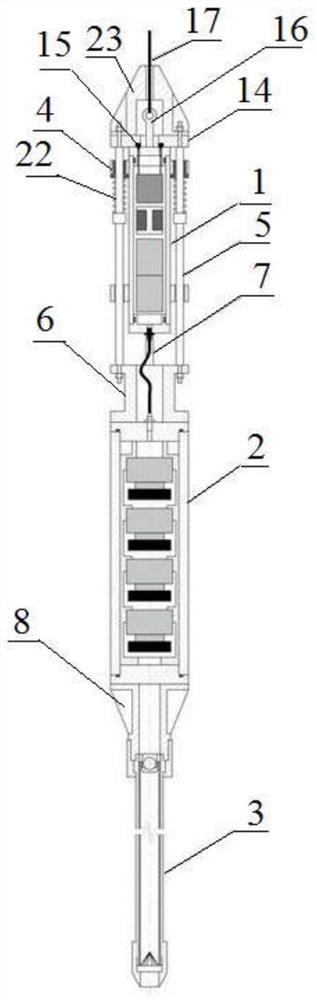

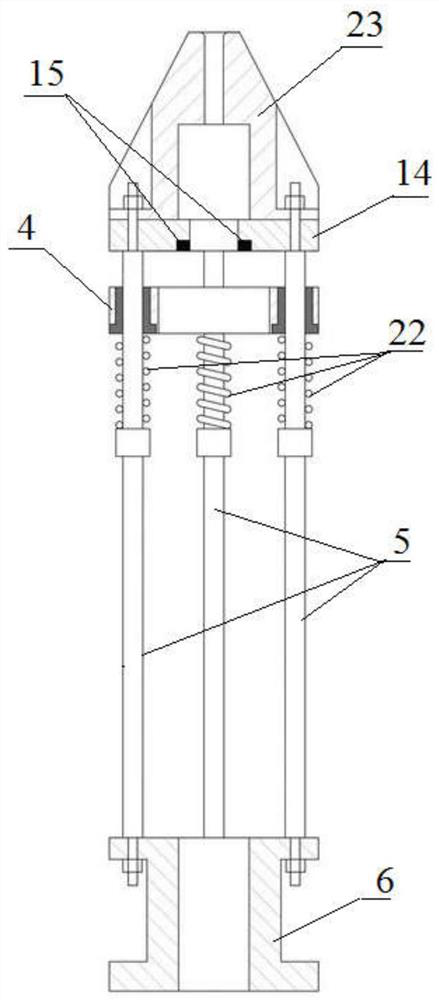

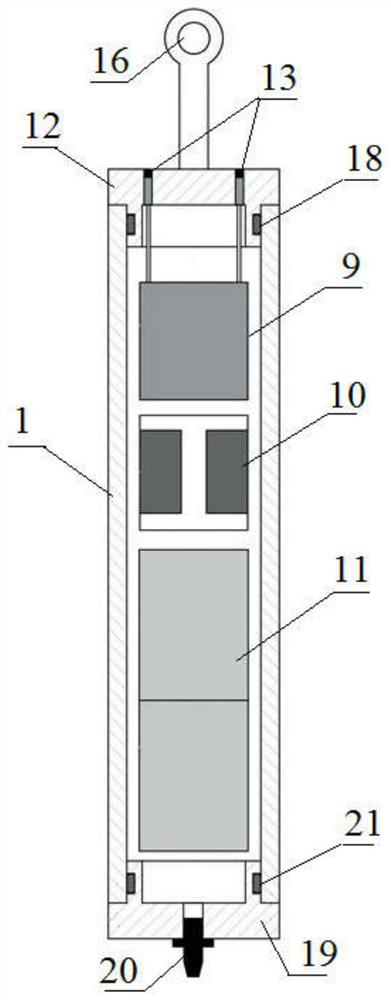

[0030] see Figure 1 to Figure 6 shown:

[0031] The fully automatic sub-ice sediment vibration sampler provided by the present invention includes a control cabin 1 , a vibration cabin 2 and a sampling tube part 3 , wherein the control cabin 1 is assembled on the upper part of the sampler body, and the control cabin 1 is sleeved through a sliding collar 4 On the guide column 5, the control cabin 1 can slide up and down along the guide column 5 driven by the sliding collar 4. The bottom of the guide column 5 is connected with the top of the vibration cabin 2 through the flange plate 6. The control device is connected with the vibration device in the vibration chamber 2 through the deep water cable 7, and the control chamber 1 transmits power and control signals to the vibration chamber 2 through the deep water cable 7. connected at the top.

[0032]The inner cavity of the control cabin 1 is provided with a voice coil motor controller 9, a transformer module 10 and a battery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com