Automatic zooming thin-film liquid lens based on temperature control and preparation method

A liquid lens, automatic zoom technology, applied in the lens, optics, instruments and other directions, can solve the problems of increasing the difficulty of device preparation, complex process preparation, small clear aperture, etc., to increase the degree of system integration, simple and convenient operation, and reduce Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

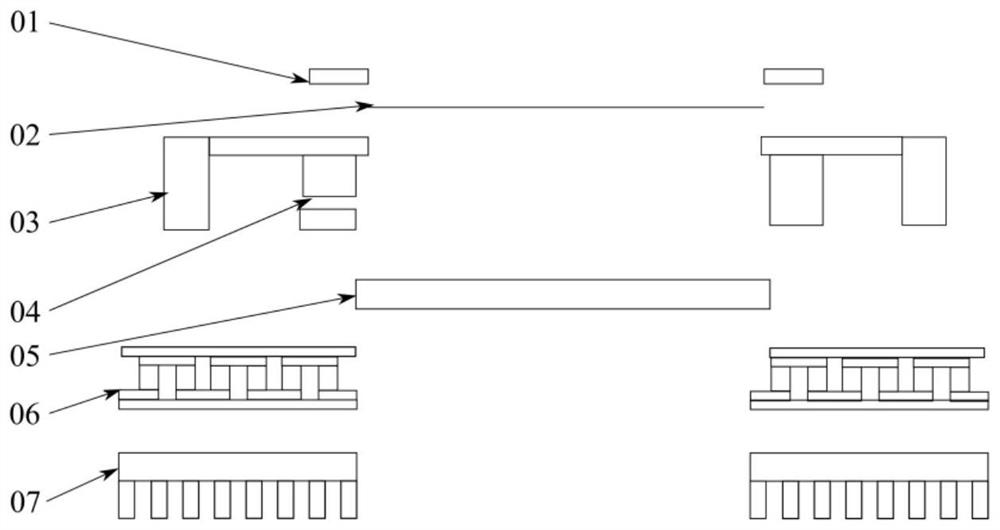

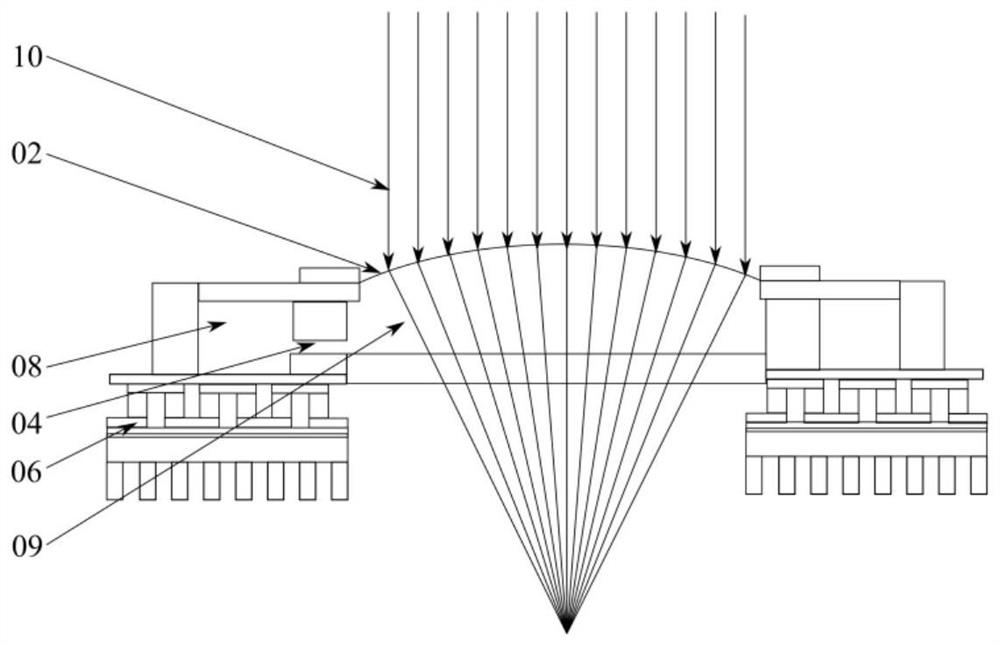

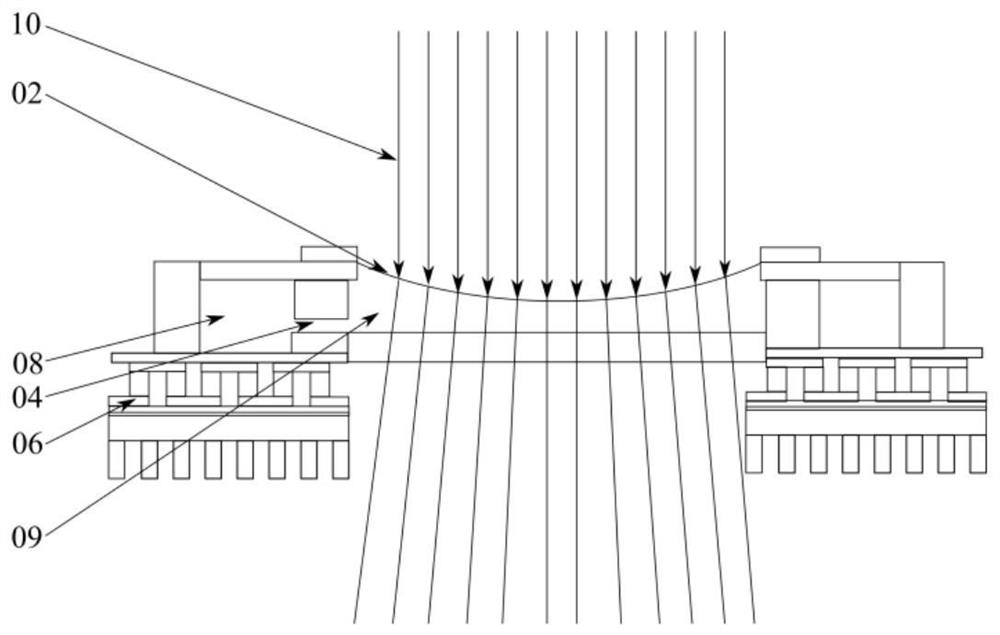

[0042] (1) The present invention proposes an automatic zoom liquid lens. as attached figure 1 As shown, the thin film liquid lens includes: thin film, optical liquid, 3D printed microchannel, micro cooling / heating sheet, and heat dissipation substrate. Using the principle of heat-gas drive, when the cooling plate is heated or cooled, the movement speed of the air molecules in the closed cavity is changed, which in turn causes a volume change, and finally controls the movement of a small amount of liquid in the closed cavity, causing the deformation of the film and realizing the automatic zoom optical lens.

[0043] (2) At normal temperature and pressure, air can be approximated as an ideal gas. The state of an ideal gas of a certain mass can be described by three state parameters P, V, T. And if any two of the parameters are determined, the third parameter mus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com