Product surface defect detection method, system and device and medium

A defect detection and product technology, applied in neural learning methods, image analysis, image enhancement, etc., can solve problems such as difficult to adapt to new product images, slow algorithm update, high time cost and labor cost, etc., to achieve fast convergence speed and heavy weight structure quality, avoid dependence, and save manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

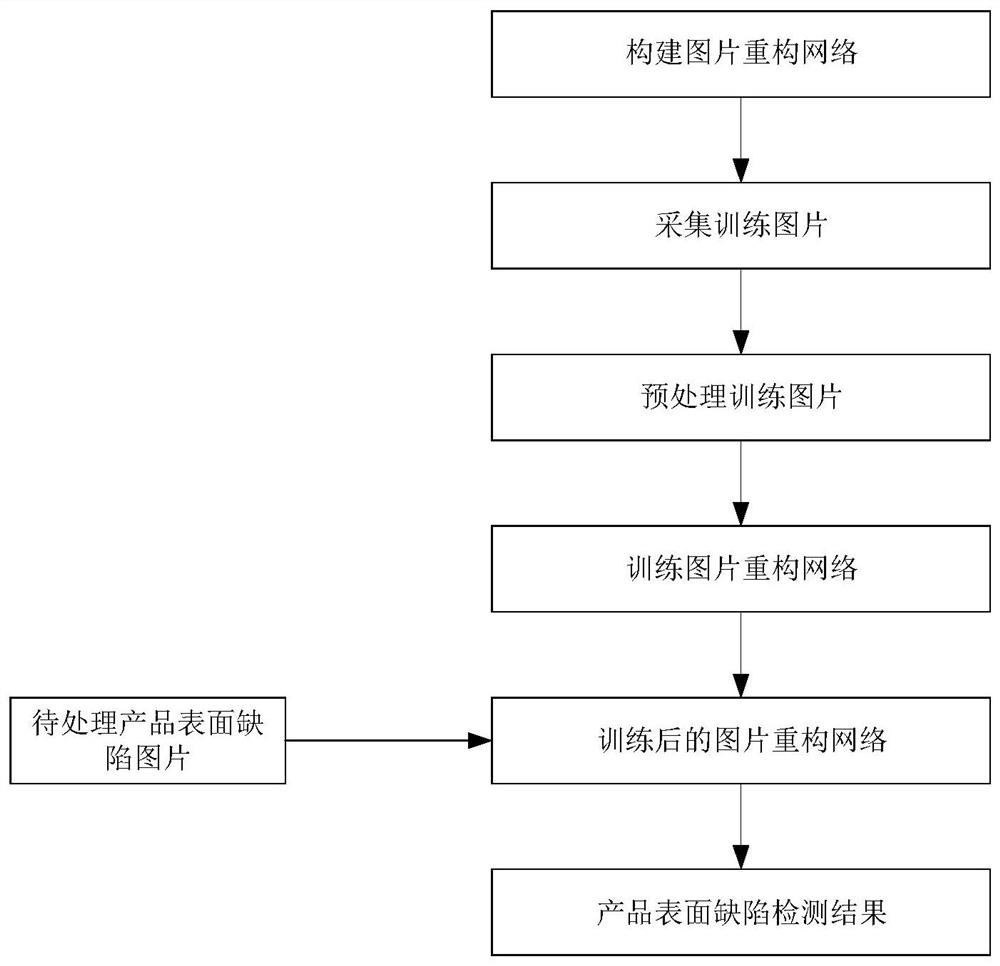

[0044] Embodiment 1 of the present invention provides a product surface defect detection method, please participate in figure 1 , figure 1 It is a schematic flow chart of a product surface defect detection method, and the method includes:

[0045] Step 1: Design a deep convolutional neural network structure based on a fully convolutional network. The process of processing images in this network mainly includes: downsampling process, upsampling process and cross-layer linking process. The downsampling process includes: multi-layer 3*3 convolution, batch normalization (batch normalize) and relu activation function. The upsampling process includes 2x upsampling, which uses an interpolation algorithm to double the size of the input feature map, a convolutional layer, batch normalization, and a relu activation function. Several feature maps in the downsampling process are directly added to the feature maps of the corresponding scales in the upsampling process, forming a cross-lay...

Embodiment 2

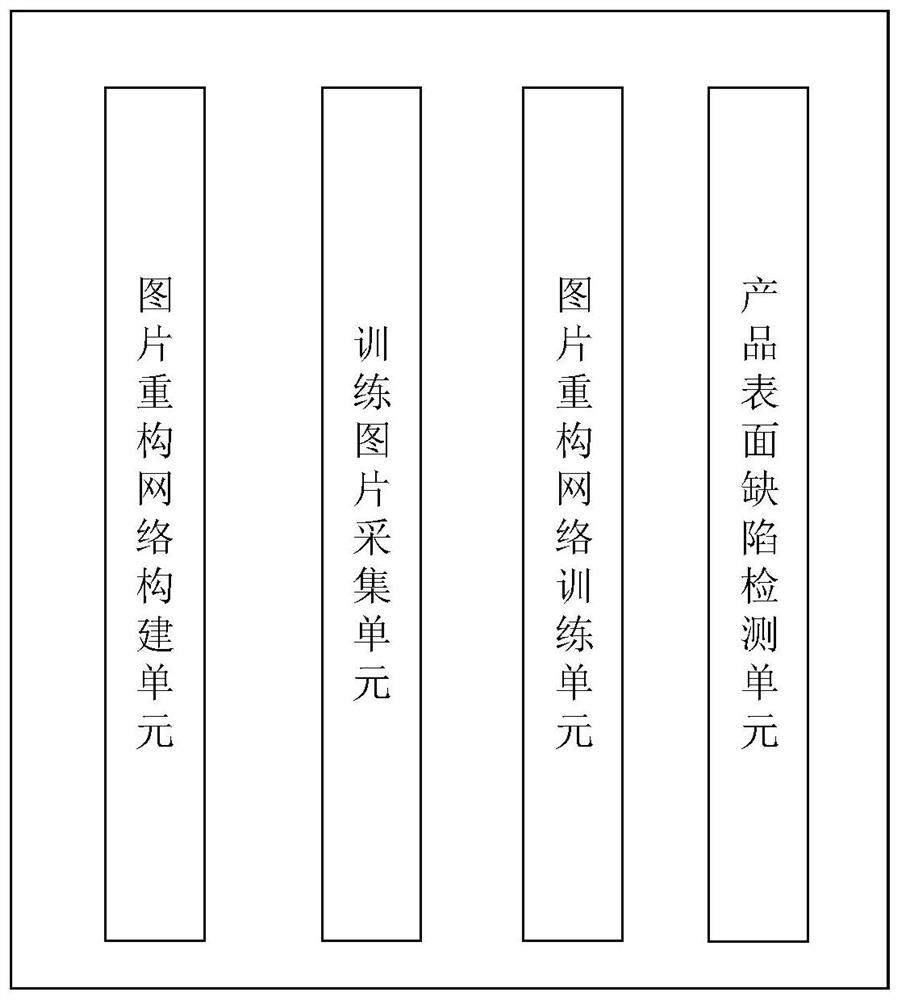

[0054] Embodiment 2 of the present invention provides a product surface defect detection system, the system comprising:

[0055] The image reconstruction network construction unit is used to construct the image reconstruction network. The image processing process of the image reconstruction network includes: downsampling process, upsampling process and cross-layer linking process; the downsampling process includes: the image is processed by the convolutional layer , then perform batch normalization processing, and then use the activation function to activate; the upsampling process includes: the image is processed through the convolutional layer, then batch normalization processing, and then activated using the activation function; the cross-layer linking process includes: Several feature maps in the downsampling process are added to the feature maps of the corresponding scales in the upsampling process;

[0056] A training picture acquisition unit, used to collect defect-free...

Embodiment 3

[0060] Embodiment 3 of the present invention provides a product surface defect detection device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the computer program, Steps for realizing the product surface defect detection method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com