A separate portable cable stripping device

A stripping device, portable technology, applied in the field of split portable cable stripping device, can solve the problems of easily scratched cable inner core, low efficiency, difficult to operate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

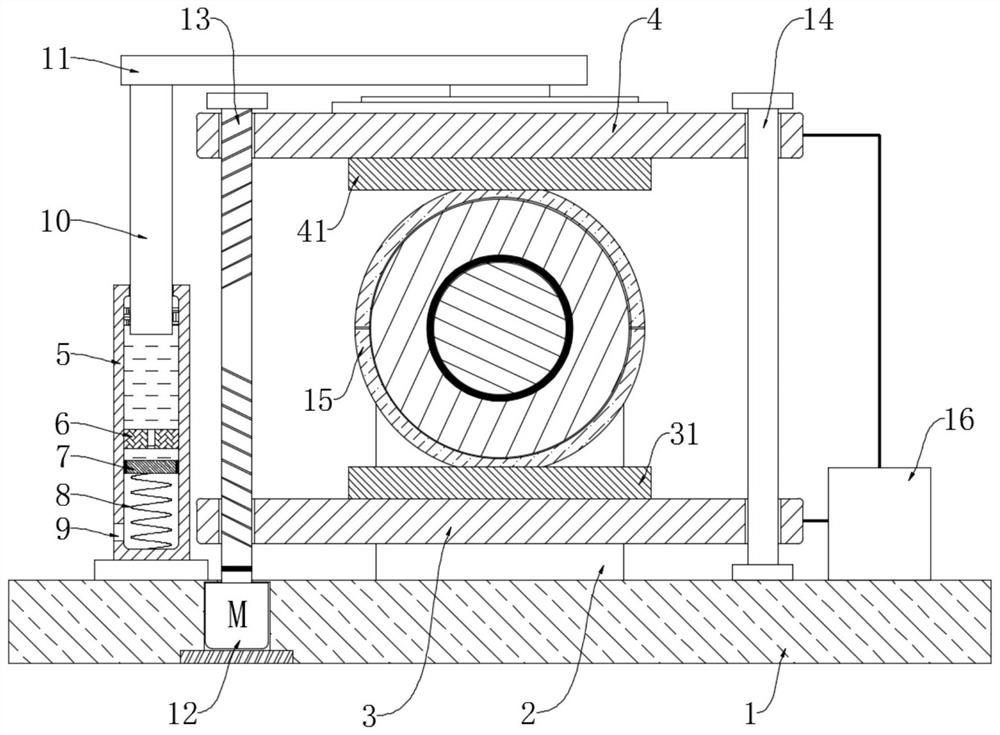

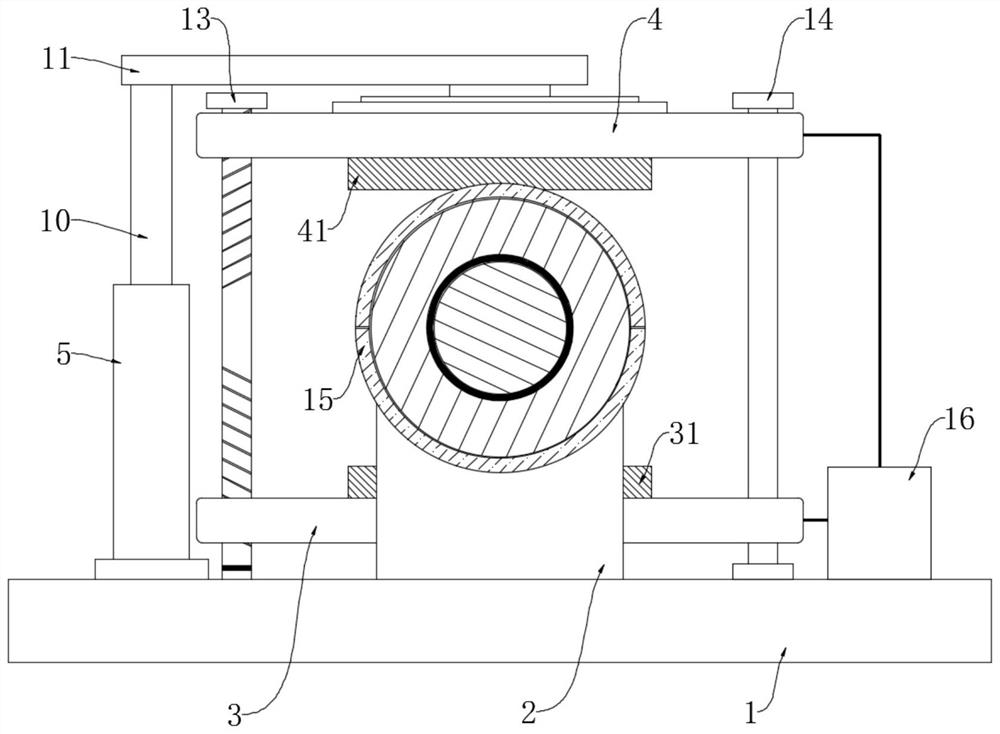

[0023] refer to Figure 1-2 , a split portable cable stripping device, including a support plate 1, a liquid storage cylinder 5, a lead screw 13, a polished rod 14 and a controller 16 are fixedly installed on the support plate 1, and an upper Fixed seat 4 and lower fixed seat 3, the opposite side of lower fixed seat 3 and upper fixed seat 4 are equipped with lower cutter body 31 and upper cutter body 41 respectively, and lower cutter body 31 and upper cutter body 41 are all connected with controller 16 connection, a low-speed motor 12 is installed in the support plate 1, and the output shaft of the low-speed motor 12 is fixedly connected with the lower end of the lead screw 13 through a coupling. Angle, has a certain self-locking property;

[0024] Because the requirements for the connection strength of the device are not high, the connection between the round rod 10 and the connecting rod 11 can be fixed by means of sleeve or clamping, and the connection between the polished...

Embodiment 2

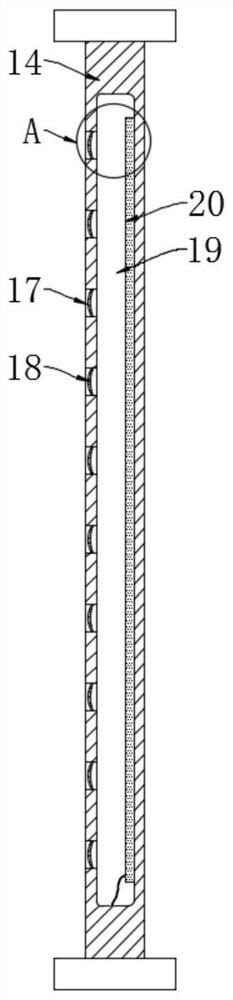

[0035] refer to Figure 3-4, the present embodiment differs from Embodiment 1 in that: a cavity 19 is provided in the polished rod 14, a temperature controller 20 is installed in the cavity 19, the temperature controller 20 is connected to the lithium battery through an independent circuit, and the side wall of the polished rod 14 There are a plurality of round holes 17 connected to the cavity 19 symmetrically on the top, and an elastic membrane body 18 is bonded in each round hole 17, and the centers of the plurality of round holes 17 are located on the same vertical line segment.

[0036] When this embodiment is used, air or low-boiling evaporative liquid can be stored in the cavity 19. Taking air as an example, when the temperature controller 20 is energized and heated, the air is heated and expands to deform the elastic membrane body 18, so that each round hole 17 An arc-shaped protrusion is formed at the center, so that the cooperation between the round rod 10 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com