Waste gas stacked denitration and desulfurization device and use method thereof

A desulfurization device and layered technology, which is applied in the field of exhaust gas layered denitration and desulfurization devices, can solve the problems affecting the efficiency and difficulty of exhaust gas denitration and desulfurization, and the increase of filter screen desorption treatment, so as to ensure the denitration and desulfurization efficiency and avoid easy aging. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

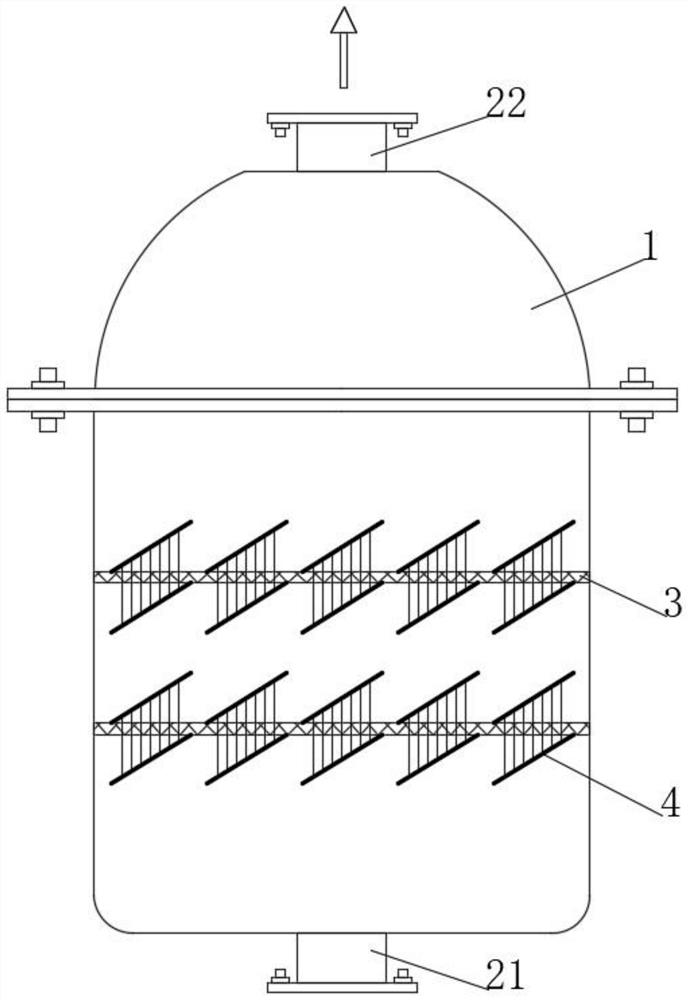

[0043] see figure 1 , a stacked exhaust gas denitrification and desulfurization device, including a device body 1, the upper and lower ends of the device body 1 are respectively fixedly connected with an outlet pipe 22 and an inlet pipe 21, and both the inlet pipe 21 and the outlet pipe 22 communicate with the inside of the device body 1, and the device body 1 is fixedly connected with a plurality of adsorption plates 3, and the adsorption plates 3 are provided with a plurality of evenly distributed two-way laminated plates 4.

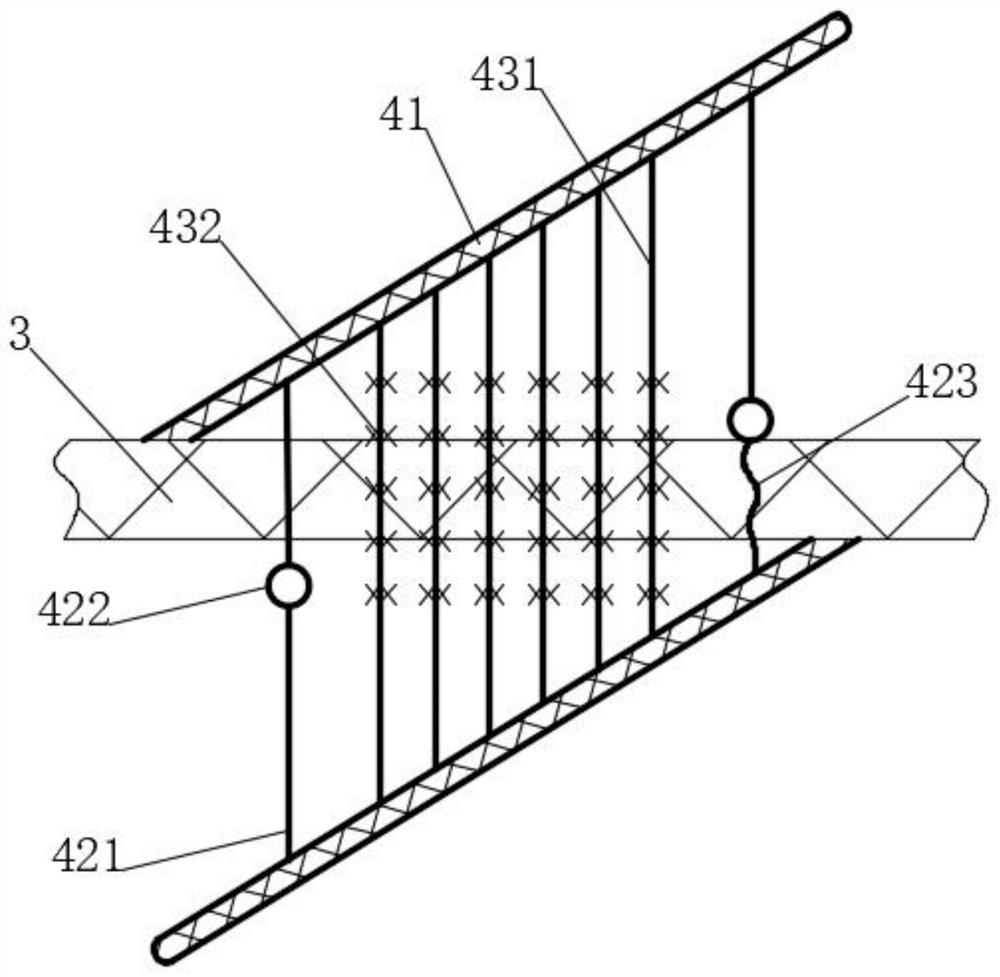

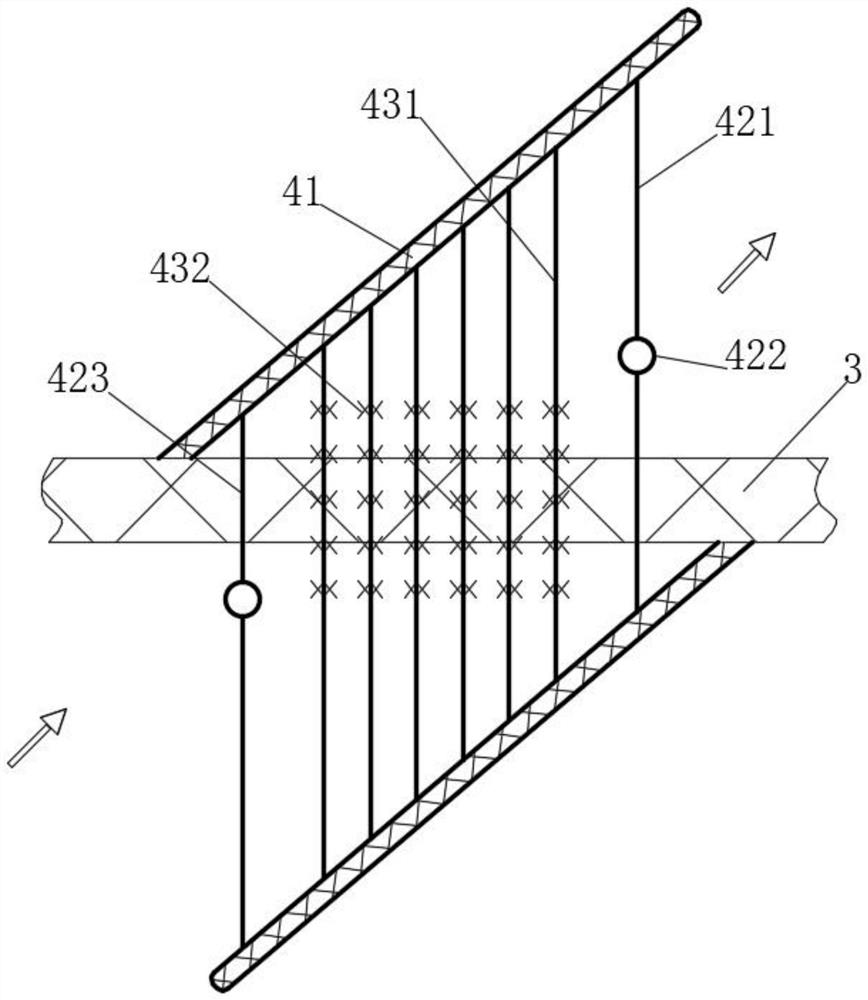

[0044] see figure 2 The two-way laminated board 4 includes two laminated sheets 41 fixedly connected to the upper and lower ends of the adsorption plate 3 respectively, and the two laminated sheets 41 are center-symmetrical, and the two ends of the two laminated sheets 41 are fixedly connected. Limited expansion ropes, a plurality of reaming ropes are fixedly connected between the middle parts of the two laminated expansion sheets 41, both the limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com