Desulfurization spray tower

A spray tower and air outlet technology, applied in the field of waste water recovery, can solve the problems of slow mixing of waste gas and spray liquid, uneven waste gas, etc., and achieve the effect of improving dust collection effect, avoiding clogging and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

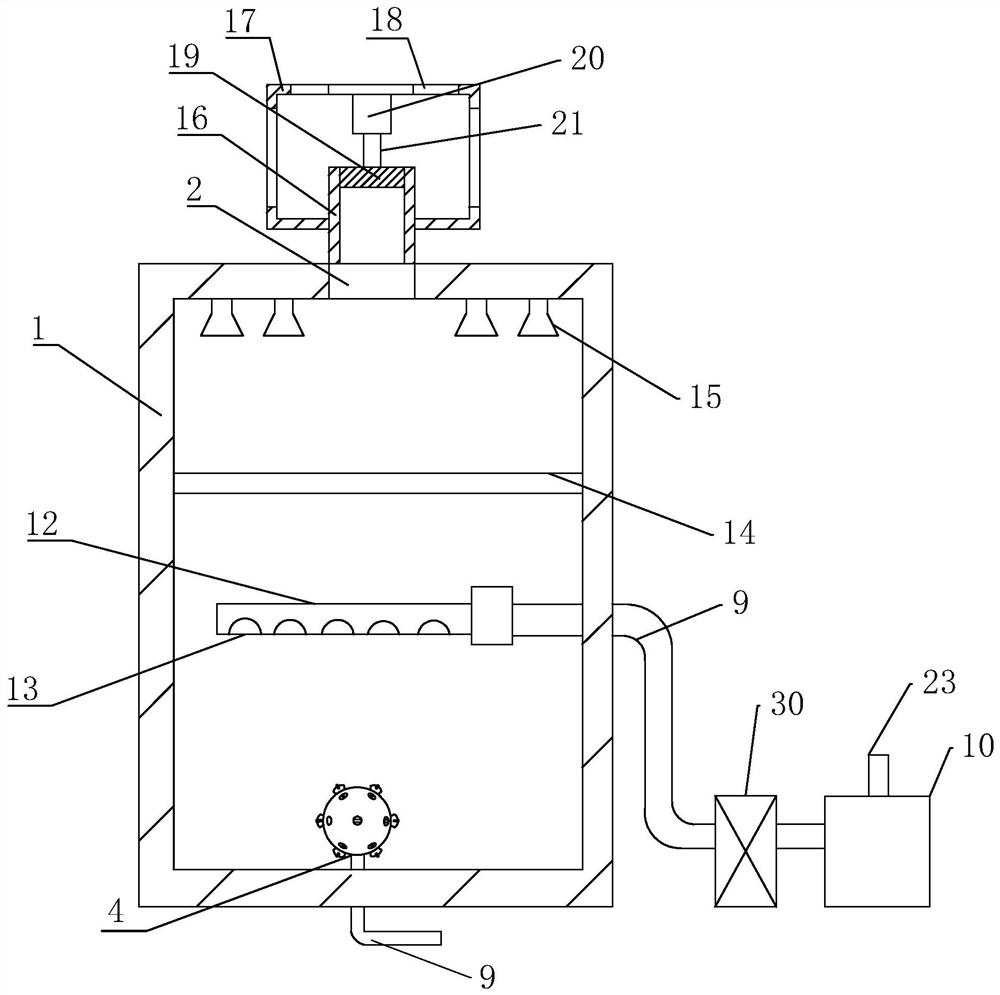

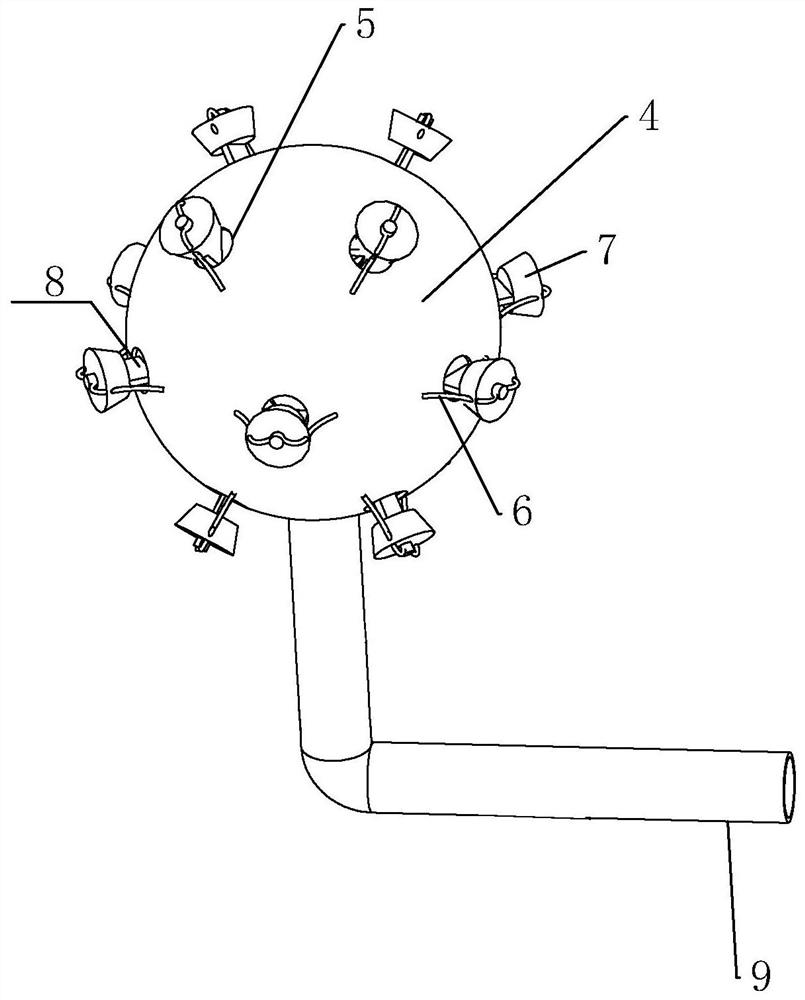

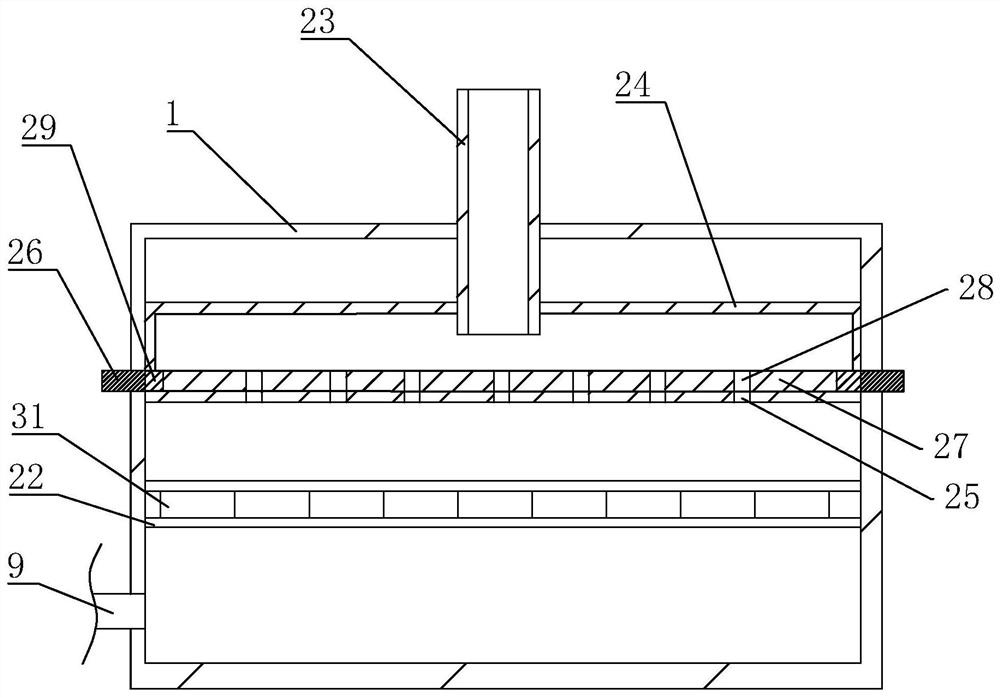

[0034] A desulfurization spray tower, such as figure 1 ,Such as image 3 , including spray tower 1, spray tower 1 includes exhaust gas outlet 2, exhaust gas outlet 2 is arranged on the top of spray tower 1, inlet pipe 3 is arranged at the bottom of spray tower 1, and liquid inlet pipe is arranged on the side wall of spray tower 1 9. One end of the liquid inlet pipe 9 extending out of the spray tower 1 is provided with a dust filter box 10 through a water pump, and the dust filter box is used to filter the exhaust gas to prevent the dust in the exhaust gas from entering the spray tower 1 and causing blockage. The dust filter box 10 is provided with an activated carbon adsorption layer 22, the activated carbon adsorption layer 22 is multi-layered, and an adsorbent 31 is filled between the two activated carbon adsorption layers 22 to improve the exhaust gas dust collection effect.

[0035] Such as figure 1 ,Such as image 3 , in order to improve the uniformity of waste gas ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com