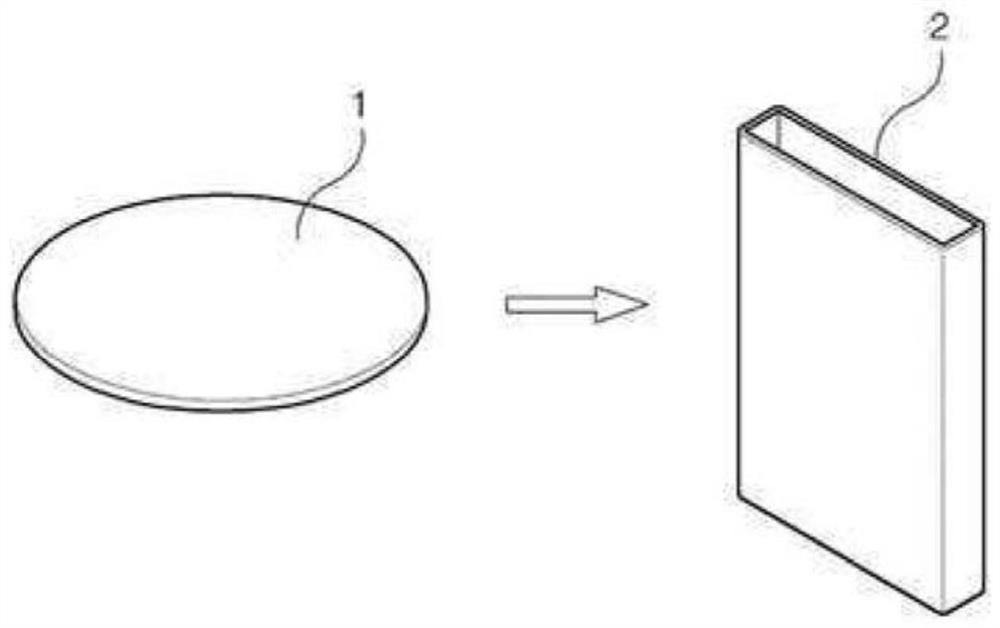

Secondary battery case molding method and secondary battery case manufactured thereby

A technology of secondary battery and molding method, which is applied in the field of secondary battery casing molding and the secondary battery casing manufactured therefrom, which can solve the problems of large load of folding deformation, uneven shape, size and appearance of deformation, etc., and achieve small load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

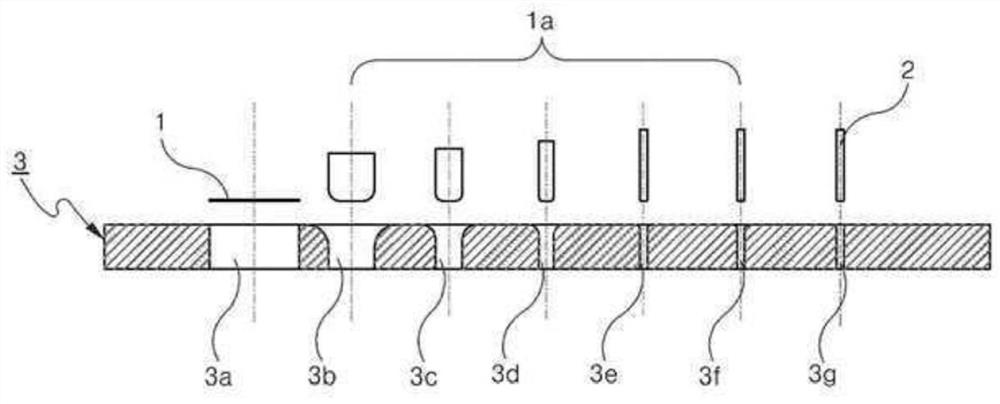

Method used

Image

Examples

experiment example

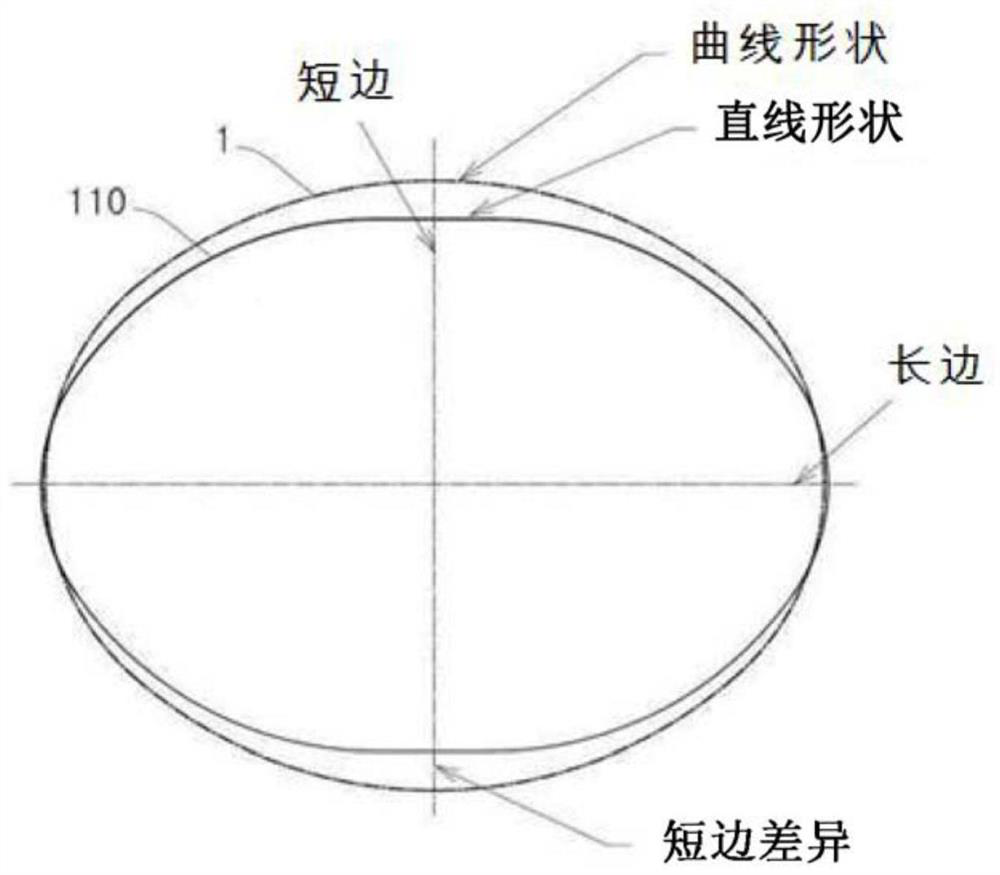

[0046] For the square shells produced in the above-mentioned examples and comparative examples, the stresses of the same process were compared with the vertical stress (predicted to fracture) generated in the direction of the main axis of the short side and their structures are shown in image 3 and Figure 4 .

[0047] Compared with the case of the comparative example, the stress is 0-13975MPa, and it is 0-5375MPa in the track shape of the present invention. It can be confirmed that the track shape of the present invention increases dimensional stability and changes the appearance while reducing the cost of materials. Be refined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com