Sintering method for preform rod powder of optical fiber

A technology of optical fiber preform and sintering method, which is applied in the field of sintering, can solve the problems of difficulty and difficulty in both sintering transparency and diameter unevenness, short sintering time, and long sintering time, so as to achieve standardized large-scale production and improve product quality. Effects of quality and productivity, shortening of sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

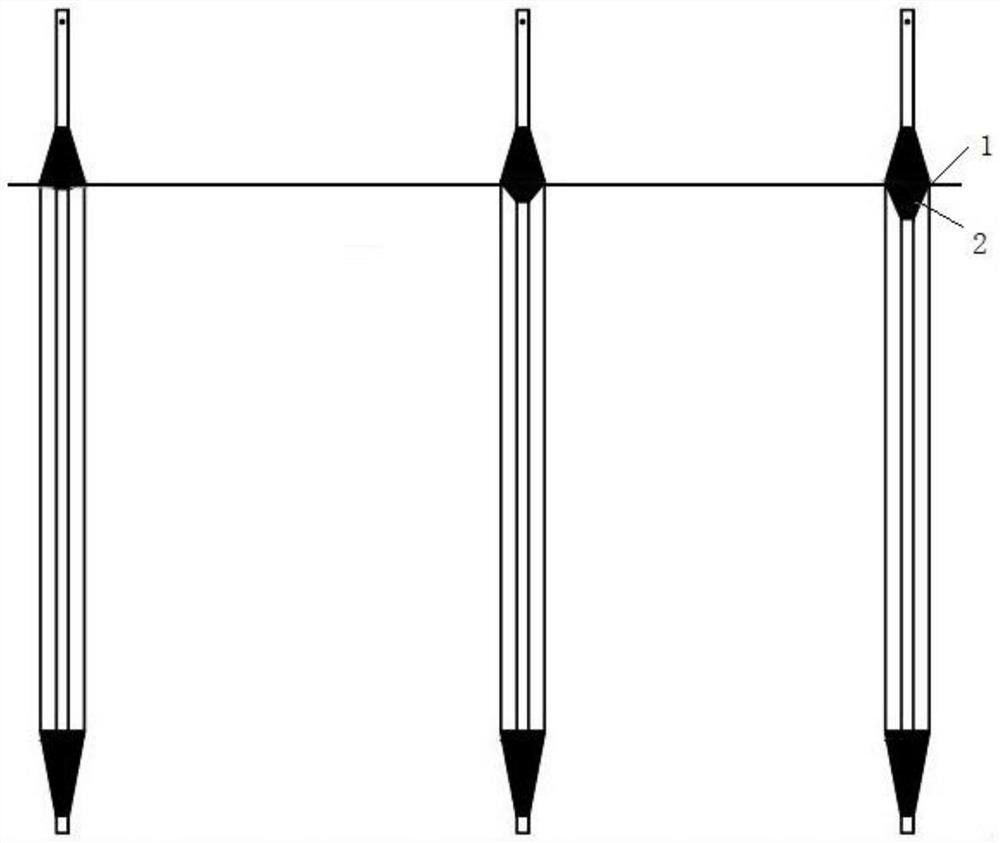

Image

Examples

Embodiment 1

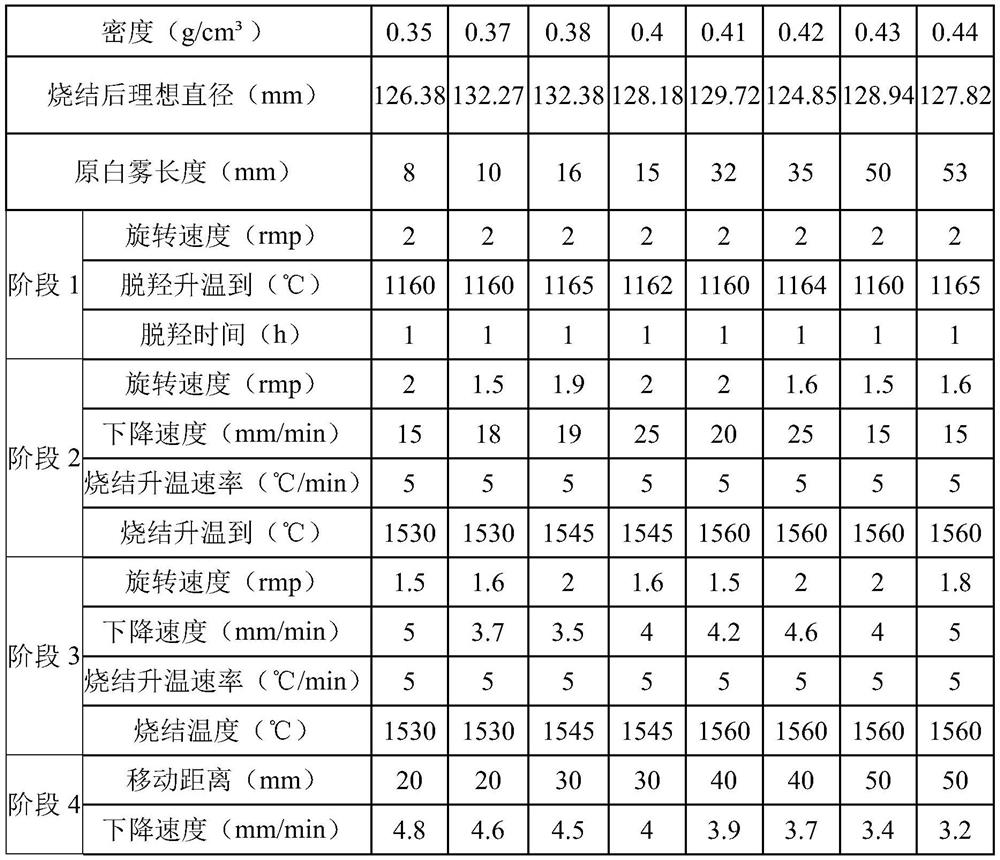

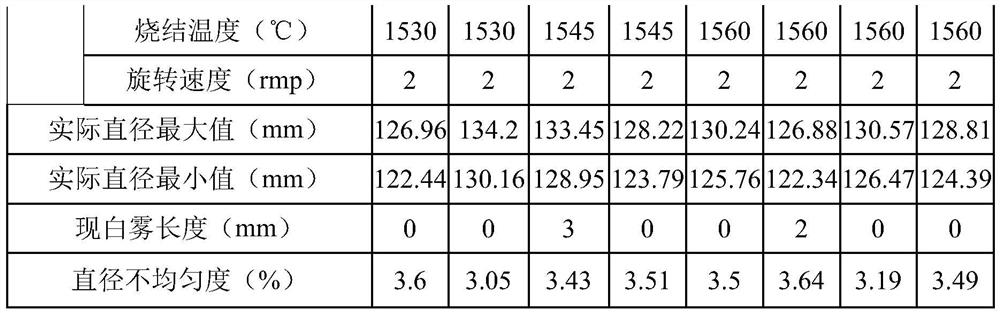

[0052] Select the preformed rod powder body for sintering, and the density of the preformed rod powder body is 0.35g / cm 3 , The ideal diameter of the preformed rod powder after sintering is 127.65mm, the theoretical diameter range is 122.54-132.75mm, and the tail handle diameter is 35mm.

[0053] Set the early warning value of the diameter of the tail shank to 33.5mm, because when the diameter of the tail shank in the sintering furnace is less than 33.5mm, the tail shank is easy to break, and the preform powder body is easy to fall into the furnace body, which will cause equipment damage.

[0054] The original process method is used for sintering, and the white mist length of the effective body part is 8mm. Sintering using the process method of this application, the downward moving distance of stage 4 is 20mm, the descending speed is 4.8mm / min, the rotation speed is 2rmp, and the temperature of the vitrification sintering zone is kept at 1530°C in stage 3. When moving down to...

Embodiment 2

[0066] Select the preformed rod powder body for sintering, and the density of the preformed rod powder body is 0.4g / cm 3 , The ideal diameter of the preformed rod powder body after firing the preformed rod powder body is 125.6mm, the theoretical diameter range is 120.57-130.62mm, and the tail handle diameter is 35mm.

[0067] Set the early warning value of the diameter of the tail shank to 33.5mm, because when the diameter of the tail shank in the sintering furnace is less than 33.5mm, the tail shank is easy to break, and the preform powder body is easy to fall into the furnace body, which will cause equipment damage.

[0068] The original process method is used for sintering, and the white mist length of the effective body part is 15mm. The process method of this application is used for sintering, and the downward moving distance of stage 4 is 30mm, the descending speed is 4.3mm / min, the rotation speed is 2rmp, and the temperature in the vitrification sintering zone is mainta...

Embodiment 3

[0084] Select the preformed rod powder body for sintering, and the density of the preformed rod powder body is 0.44g / cm 3 , The ideal diameter of the preformed rod powder after sintering is 126.38mm, the theoretical diameter range is 121.32-131.43mm, and the tail handle diameter is 35mm.

[0085] Set the early warning value of the diameter of the tail shank to 33.5mm, because when the diameter of the tail shank in the sintering furnace is less than 33.5mm, the tail shank is easy to break, and the preform powder body is easy to fall into the furnace body, which will cause equipment damage.

[0086] Sintered by the original process method, the length of the white mist of the effective body part is 53mm. The process method of the present application is used for sintering, and the downward moving distance of stage 4 is 50mm, the descending speed is 4.3mm / min, the rotation speed is 2rmp, and the temperature of the vitrification sintering zone is maintained at 1560°C in stage 3. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com