A kind of manufacturing method of physically sensitized deep water blasting emulsion explosive

An emulsion explosive and manufacturing method technology, which is applied to explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of increased production cost, poor data reliability, complicated test procedures, etc., and achieve stable production quality, The effect of preventing mechanical wear and increasing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

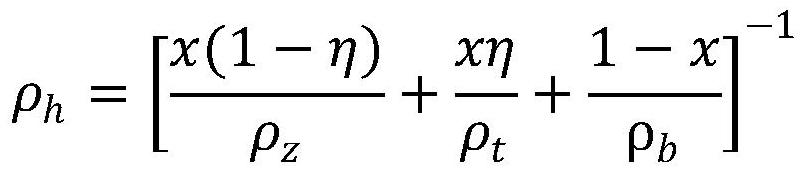

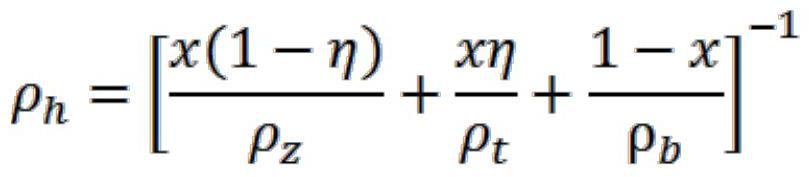

[0024] A hollow glass microbead is used as a physical sensitizer, preparing deep water emulsified explosives, testing the microbeads true density ρ z 0.202g / cm 3 The pressure of 10 h was pressed under 3ATM pressure, and the calculation rate η was 27.926%. Treatment of glass microbea ionure, prepared emulsified explosives with a mixture of 3.6% by mass concentration x and emulsified matrix, and the normal pressure density is 1.180g / cm. 3 When the open-air blasting is normal, the explosion is 5037m / s. Press the explosive under 3ATM pressure under pressure, completely refused, and calculate the explosive density in formula. h 1.246G / cm 3 (Glass density ρ t Take 2.2g / cm 3 Emulsified explosive matrix density ρ b Take 1.44g / cm 3 ).

Embodiment 2

[0026] A hollow glass microbead is used as a physical sensitizer, preparing deep water emulsified explosives, testing the microbeads true density ρ z 0.213g / cm 3The pressure of 10 h was pressed under 3ATM pressure, and the calculated ratio η was 15.98%. Treatment of glass microbeads, according to the glass microbead mass concentration X is 3.6% mixed with emulsified matrix, and the normal pressure density is 1.192g / cm. 3 When the open-air blasting is normal, the explosion is 5578m / s. Press the explosives under 3ATM pressure under pressure 12h, half-burst, calculate the explosive density ρ according to the formula h 1.228g / cm 3 (Glass density ρ t Take 2.2g / cm 3 Emulsified explosive matrix density ρ b Take 1.44g / cm 3 ).

Embodiment 3

[0028] A hollow glass microbead is used as a physical sensitizer, preparing deep water emulsified explosives, testing the microbeads true density ρ z 0.212g / cm 3 The pressure of 10 h was pressed under 3ATM pressure, and the calculated ratio η was 15.98%. Treatment of glass microbeads, according to the glass microbead mass concentration x is 4.2% mixed with emulsified matrix, and the normal pressure density is 1.158g / cm. 3 When the open-air blasting is normal, the explosion is 5240 m / s. The explosives were pressed against 24 h at 3ATM pressure, normally detonated, and the test explosion was 5385m / s. Calculate the explosive density in formula ρ h 1.197G / cm 3 (Glass density ρ t Take 2.2g / cm 3 Emulsified explosive matrix density ρ b Take 1.44g / cm 3 ).

[0029] The formula has been applied to the underwater project of Dalian Bay Hail Tunnel Construction Engineering, the blasting water depth is 10 ~ 30m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com