Imide-bridged polysiloxane gas separation membrane and preparation method thereof

A technology of gas separation membrane and polysiloxane, which is applied in the direction of separation method, semipermeable membrane separation, dispersed particle separation, etc., can solve the problems of mutual restriction of gas permeability and selectivity, and achieve increased free volume and good permeability Sexual, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific technical solutions of the present invention are described in conjunction with the examples.

[0018] An imide-bridged polysiloxane gas separation membrane, the preparation method of which is as follows:

[0019] (1) In a reaction vessel filled with nitrogen, add a THF solution of pentamethylcyclotrisiloxane, stir in a dry ice and acetone mixed bath to below -78°C, then add lithium trimethylsiloxane and continue at -78°C React for 4 hours; then add trimethylchlorosilane, the molar ratio of each material is 1:100:0.2:0.04, continue to react for 5 hours, remove the solvent by rotary evaporation under reduced pressure to an oily substance.

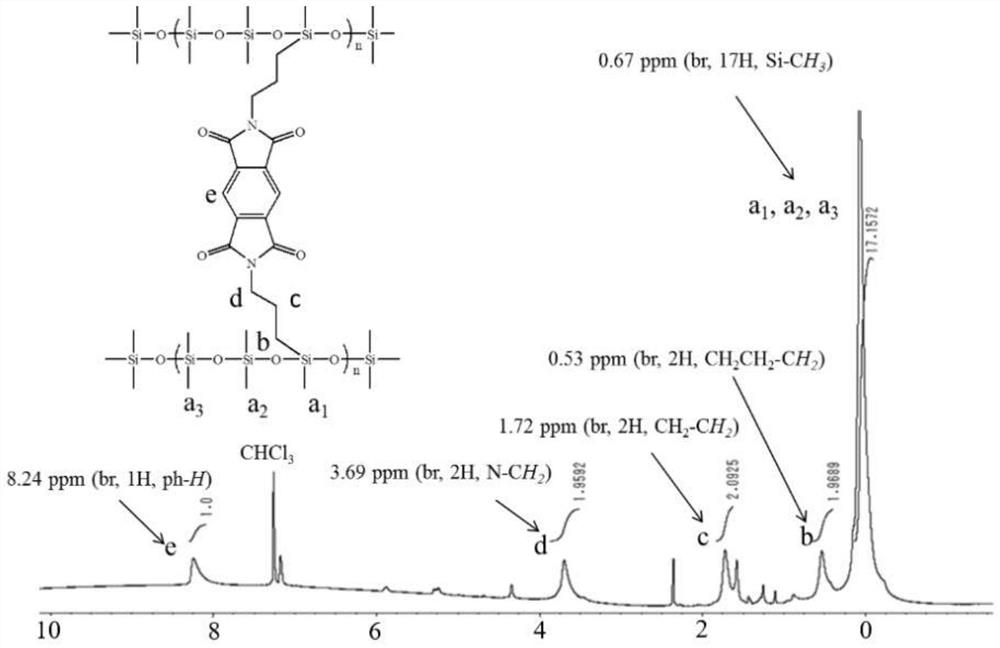

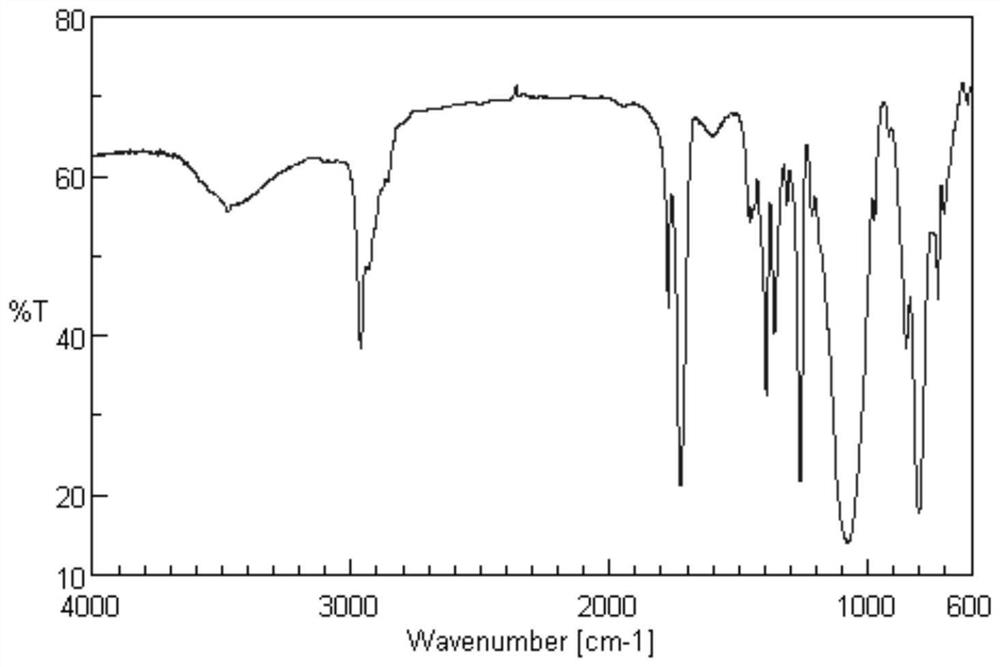

[0020] (2) Under nitrogen protection, add diallyl imide in the reaction vessel, then add Karstedt catalyst, freshly steam toluene and step (1) gained oil and stir for 15 hours, filter to remove insoluble matter, pour ether , the unreacted compound was precipitated, and the precipitate was removed by filtration. After rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com